In essence, multiple-chamber vacuum furnaces outperform single-chamber designs by separating the heating and cooling processes into different physical modules. This fundamental design difference leads to major advantages in energy efficiency, production throughput, and equipment longevity by eliminating the need for the hot zone to cool down and reheat between every batch.

The core advantage of a multi-chamber vacuum furnace is its transformation of heat treatment from a slow, energy-intensive batch process into a highly efficient, continuous production flow. By keeping the heating chamber consistently hot, you minimize energy waste, accelerate production cycles, and reduce mechanical stress on the equipment.

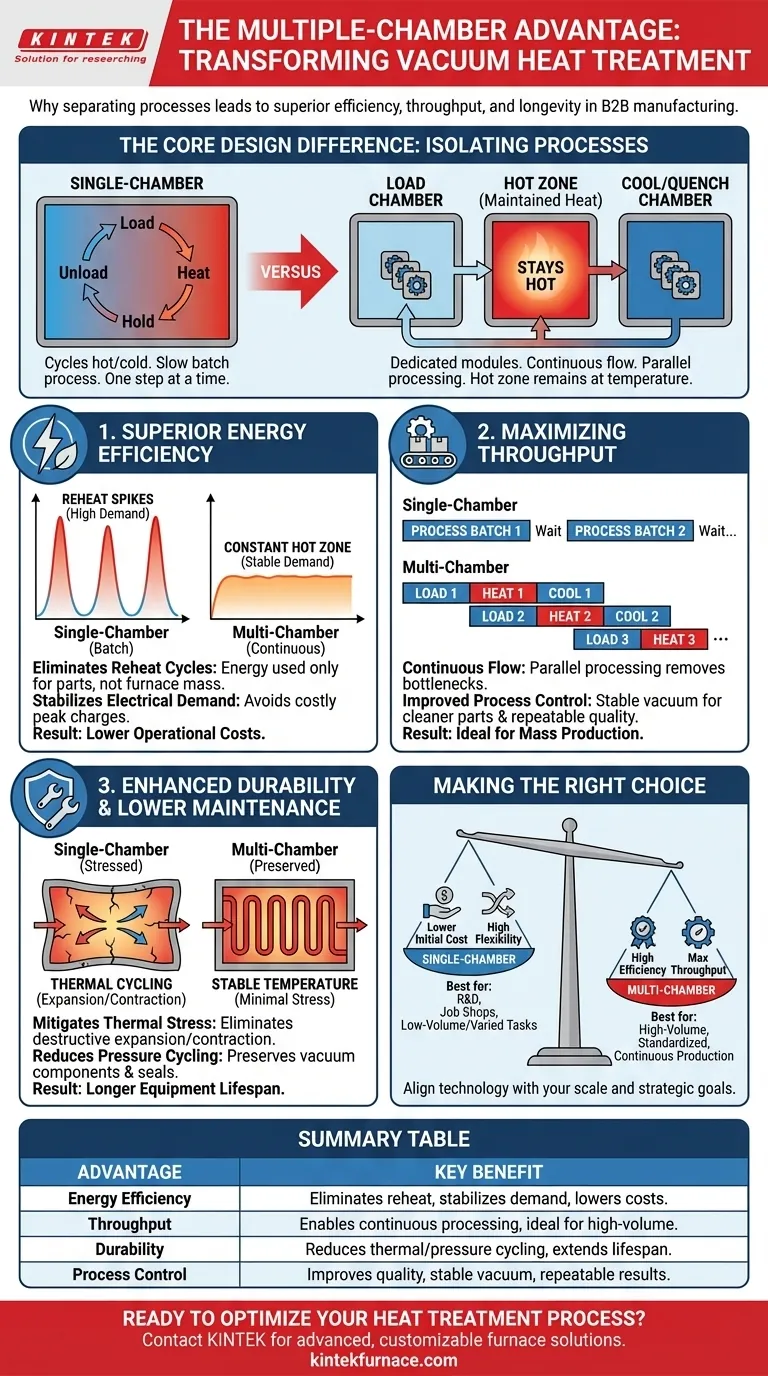

The Core Design Difference: Isolating Processes

The functional superiority of a multiple-chamber furnace stems from one simple principle: dedicating separate, isolated chambers for distinct process steps.

The Single-Chamber Limitation

A single-chamber furnace must perform every step—pumping down, heating, holding at temperature, and cooling or quenching—in the same space. This requires the chamber and all its internal components to cycle through extreme temperature and pressure changes with every load.

The Multi-Chamber Advantage

A multiple-chamber system moves the workload between specialized chambers. A typical flow involves a loading chamber, a dedicated hot zone that remains at temperature, and a separate cooling or quenching chamber. This allows multiple loads to be in different stages of the process simultaneously.

Advantage 1: Superior Energy Efficiency

By not cooling the hot zone for every cycle, multi-chamber furnaces achieve significant energy savings and operational cost reductions.

Eliminating Reheat Cycles

The single largest energy expenditure in batch processing is reheating the furnace from a cooled state. In a multi-chamber design, the heat is retained in the hot zone, ready for the next load.

The available energy is consumed almost exclusively by the parts being treated, not by the furnace itself. This dramatically lowers the energy cost per pound of processed material.

Stabilizing Electrical Demand

Single-chamber furnaces create massive spikes in electrical demand as they ramp up to temperature. A multi-chamber furnace, by maintaining a constant hot zone temperature, draws a much more consistent and predictable electrical load, reducing or eliminating costly peak-demand charges from utility providers.

Advantage 2: Maximizing Throughput for Mass Production

The ability to process loads continuously makes multiple-chamber furnaces ideal for modern industrial-scale production.

From Batch to Continuous Flow

While one load is cooling, the next load can already be in the hot zone. This parallel processing overcomes the primary bottleneck of single-chamber designs, which are inherently unsuited for high-volume manufacturing.

This continuous model significantly increases productivity and overall output, making it the standard for applications that require consistent, large-scale results.

Improved Process Control and Quality

Dedicated chambers allow for more precise control over each step. The constant, stable vacuum in the hot zone prevents oxidation from moisture contamination that can occur during pressure cycling. This results in cleaner part surfaces, minimal decarburization, and superior metallurgical repeatability.

Advantage 3: Enhanced Durability and Lower Maintenance

Maintaining a stable environment within the furnace chambers dramatically reduces wear and tear, extending the equipment's lifespan.

Mitigating Thermal Stress

The repeated expansion and contraction caused by thermal cycling is a primary cause of fatigue and failure in furnace components like heating elements, insulation, and the chamber itself. By keeping the hot zone at a stable temperature, this destructive stress is virtually eliminated.

Reducing Pressure Cycling

Likewise, the hot zone is not subjected to constant pressure cycling between deep vacuum and atmospheric pressure. This preserves the integrity of the furnace casing, seals, and vacuum components, leading to a longer operational life and fewer maintenance interventions.

Understanding the Trade-offs

While powerful, a multiple-chamber system is not the universal solution. The primary trade-off is between operational efficiency and initial investment.

A multi-chamber furnace represents a higher capital expenditure and is more complex. Its benefits are most fully realized in high-volume, standardized production environments where efficiency and cost-per-part are the dominant concerns.

A single-chamber furnace offers a lower initial investment and greater flexibility. It is often a more practical choice for research and development, job shops with highly varied parts and processes, or low-volume production where the costs of a continuous system cannot be justified.

Making the Right Choice for Your Operation

Your decision should be guided by your specific production goals, volume, and budget.

- If your primary focus is high-volume, continuous production: A multiple-chamber furnace is the definitive choice for its superior throughput and low cost-per-part.

- If your primary focus is long-term operational cost reduction: The energy savings and reduced maintenance of a multi-chamber system provide a clear return on investment.

- If your primary focus is process flexibility for low-volume or varied tasks: A single-chamber furnace offers a more versatile and cost-effective entry point for vacuum heat treatment.

Ultimately, choosing the right furnace architecture is about aligning the technology with the scale and strategic goals of your operation.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Energy Efficiency | Eliminates reheat cycles, stabilizes electrical demand, lowers operational costs |

| Throughput | Enables continuous processing, ideal for high-volume mass production |

| Durability | Reduces thermal and pressure cycling, extends equipment lifespan |

| Process Control | Improves quality with stable vacuum, cleaner parts, and repeatable results |

Ready to optimize your heat treatment process? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in high-volume production or need flexible solutions, we can help you achieve superior efficiency and quality. Contact us today to discuss how our furnaces can benefit your operation!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety