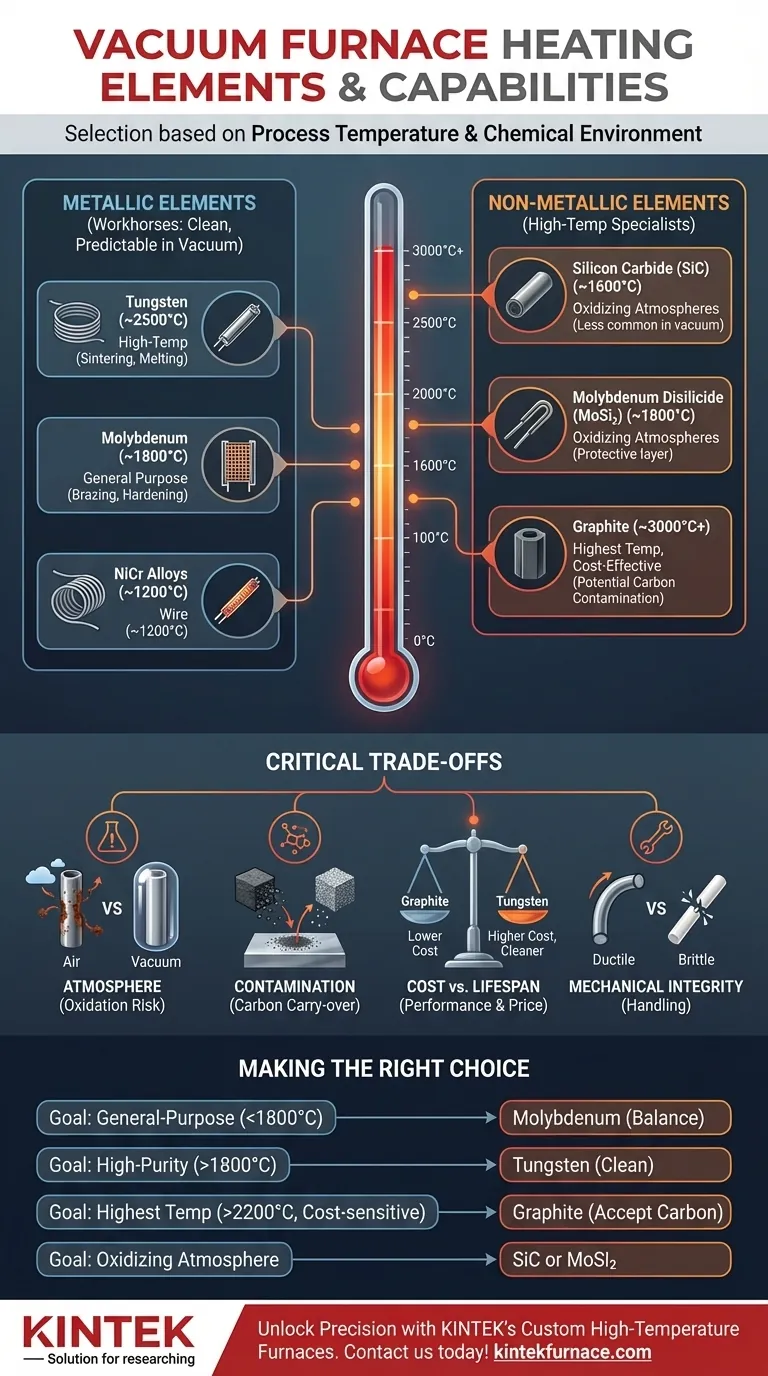

The selection of a heating element for a vacuum furnace is dictated by the required process temperature and the chemical environment inside the chamber. The most common materials are metallic alloys, pure refractory metals like molybdenum and tungsten, and non-metallic compounds like graphite and silicon carbide. These elements cover a wide operational range, from approximately 750°C for basic alloys to over 3000°C for specialized graphite designs.

The optimal heating element is not simply the one that gets hottest. It represents a critical trade-off between maximum temperature, chemical compatibility with your process, furnace longevity, and overall cost.

Heating Element Materials and Temperature Ranges

Heating elements for vacuum furnaces are broadly categorized into metallic and non-metallic types. Each has a distinct temperature range and set of operational characteristics.

Metallic Elements: The Workhorses

Metallic elements are prized for their cleanliness and predictable performance in high-vacuum environments.

-

Resistance Wire Alloys (up to ~1200°C): For lower-temperature vacuum applications, nickel-chromium (NiCr) and similar resistance alloys are effective. They are robust and cost-effective but limited in their peak temperature.

-

Molybdenum (up to ~1800°C): Molybdenum, or "moly," is the most common heating element for general-purpose vacuum furnaces. It provides excellent performance for processes like brazing, annealing, and hardening. It requires a vacuum or inert atmosphere to prevent rapid oxidation.

-

Tungsten (up to ~2500°C): For temperatures beyond the capability of molybdenum, tungsten is the preferred choice. It has an extremely high melting point and is used for high-temperature sintering, melting, and other demanding applications.

Non-Metallic Elements: The High-Temp Specialists

Non-metallic elements offer superior temperature capabilities but often come with specific operational considerations.

-

Silicon Carbide (SiC) (up to ~1600°C): While capable of high temperatures, SiC is more commonly used in furnaces with air or oxidizing atmospheres. In vacuum furnaces, it is less common than molybdenum but can be found in certain specialized designs.

-

Molybdenum Disilicide (MoSi₂) (up to ~1800°C): Like SiC, MoSi₂ elements are known for their excellent performance in oxidizing environments. They form a protective silica layer that makes them less suitable for high-vacuum applications where this layer can become unstable.

-

Graphite (up to ~3000°C): Graphite is the undisputed leader for achieving the highest possible temperatures in a vacuum furnace. It is lightweight, has excellent thermal shock resistance, and is relatively inexpensive.

A Note on Induction Heating

Induction coils are also listed as a heating method. This is fundamentally different from resistance heating. Instead of the element getting hot, an induction coil generates a powerful magnetic field that directly heats the electrically conductive material (the "workpiece") inside the furnace.

Understanding the Critical Trade-offs

Choosing an element based solely on its maximum temperature is a common mistake. The true challenge lies in balancing performance with practical limitations.

Temperature vs. Atmosphere

Refractory metals like molybdenum and tungsten will rapidly oxidize and fail if operated at high temperatures in the presence of oxygen. They demand a high-quality vacuum or a pure inert gas atmosphere (like argon or nitrogen). This is the primary reason materials like SiC or MoSi₂ are used in air furnaces.

Performance vs. Contamination

Graphite is not a "clean" heat source. At high temperatures, it can outgas and shed fine carbon particles. This "carbon carry-over" can contaminate sensitive materials, making graphite unsuitable for processes where carbon interaction is a concern, such as with certain titanium or refractory metal alloys.

Cost vs. Lifespan

There is a direct correlation between performance and cost. Graphite is often the most cost-effective option for very high-temperature work. Tungsten is significantly more expensive but offers a cleaner, high-performance alternative. Molybdenum sits in the middle, providing a balanced solution for a wide range of applications.

Mechanical Integrity

Heating elements also differ in their physical properties. Graphite and ceramic-based elements are brittle and require careful handling and furnace design. Metallic elements like molybdenum and tungsten are more ductile at room temperature, simplifying installation and maintenance.

Making the Right Choice for Your Goal

Your process requirements should be the definitive guide for selecting a furnace and its heating element system.

- If your primary focus is general-purpose brazing or heat treating (<1800°C): Molybdenum offers the best balance of performance, cleanliness, and cost for a vast majority of vacuum applications.

- If your primary focus is high-purity, high-temperature work (>1800°C): Tungsten is the superior choice when carbon contamination from graphite is not permissible.

- If your primary focus is achieving the highest temperatures (>2200°C) and cost is a major factor: Graphite is the go-to material, provided its potential for carbon contamination is acceptable for your process.

- If you are operating in an air or oxidizing atmosphere: Molybdenum, tungsten, and graphite are unsuitable; you must use elements like silicon carbide (SiC) or molybdenum disilicide (MoSi₂).

Understanding these fundamental differences empowers you to select a system that delivers not just heat, but the precise environment your process needs to succeed.

Summary Table:

| Material Type | Examples | Max Temperature | Key Characteristics |

|---|---|---|---|

| Metallic | NiCr Alloys, Molybdenum, Tungsten | Up to 2500°C | Clean, predictable in vacuum, requires inert atmosphere |

| Non-Metallic | Silicon Carbide, Graphite | Up to 3000°C | High-temperature specialists, may cause contamination |

Unlock Precision in Your Lab with KINTEK's Custom High-Temperature Furnaces

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need molybdenum elements for brazing or graphite for extreme temperatures, we deliver reliable, tailored systems that enhance efficiency and results.

Contact us today to discuss how our furnaces can solve your specific challenges and elevate your research or production processes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision