In short, the requirements for a sealed vacuum furnace shell center on three critical functions: achieving a perfect seal to maintain vacuum, possessing the structural strength to withstand atmospheric pressure, and having an effective cooling system to prevent thermal deformation. These elements work together to create a stable, controlled environment essential for high-quality thermal processing.

The furnace shell is not merely a container; it is a high-performance system designed to isolate a process from the outside atmosphere. Its success hinges on a perfect balance between impenetrable sealing, structural rigidity against immense external forces, and precise temperature control of the shell itself.

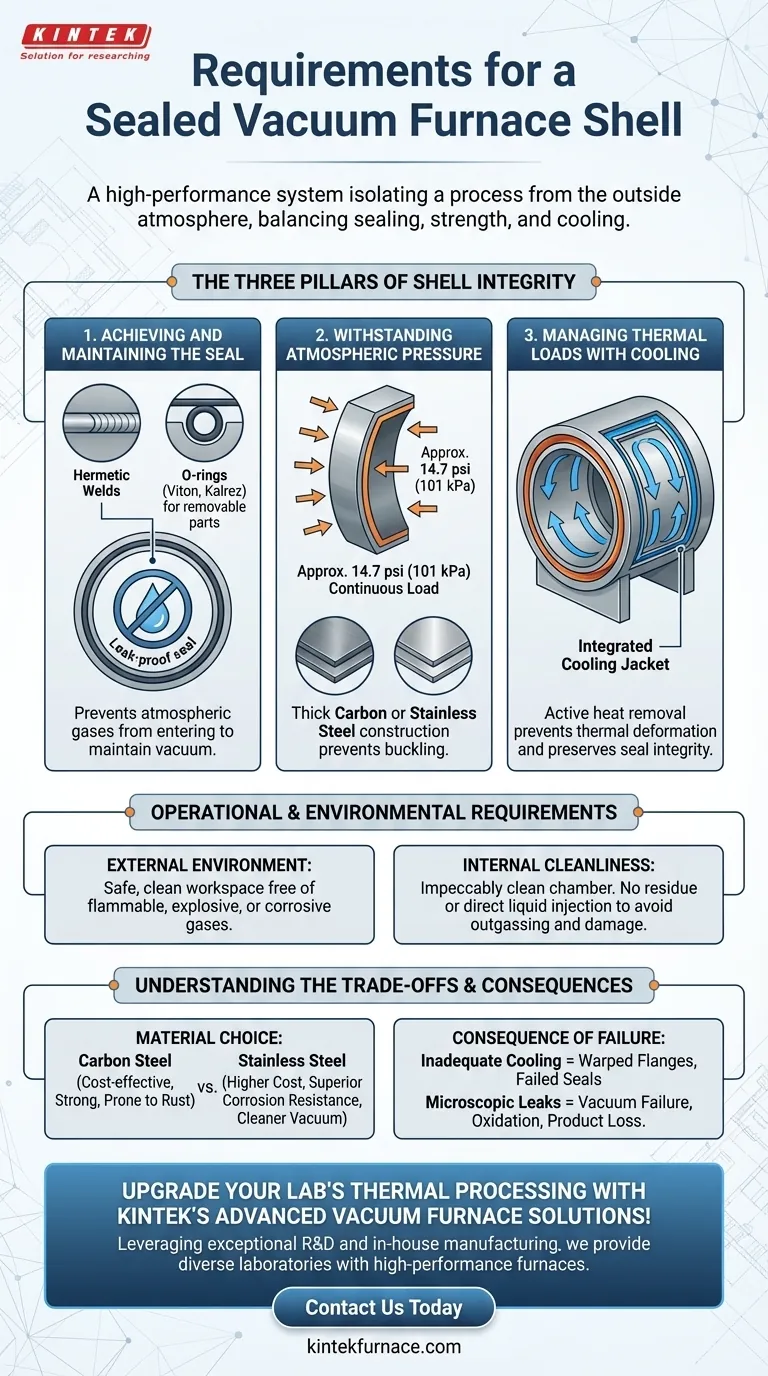

The Pillars of Furnace Shell Integrity

A vacuum furnace's performance is fundamentally tied to the quality of its sealed shell. Each design requirement addresses a specific physical challenge inherent to creating a vacuum next to a high-temperature process.

Pillar 1: Achieving and Maintaining the Seal

The primary function of the shell is to be airtight. Any failure to seal properly makes achieving the target vacuum impossible.

Welds are the first line of defense. All permanent joints of the furnace shell must be expertly welded to ensure they are hermetic and free of any porosity that could cause a leak.

For removable components like doors or maintenance ports, specialized vacuum sealing materials are used. These are typically O-rings made from elastomers like Viton or Kalrez, which are compressed to create a reliable, reusable seal.

Pillar 2: Withstanding Atmospheric Pressure

When a deep vacuum is pulled inside the furnace, the shell must withstand the full force of atmospheric pressure—approximately 14.7 pounds per square inch (or 101 kilopascals)—pressing on every part of its exterior surface.

This immense, continuous load requires a robust structure. The shell is typically fabricated from thick carbon steel or stainless steel plates, reinforced as needed to prevent buckling or collapse.

The choice of material depends on budget and application. Carbon steel is a cost-effective and strong solution, while stainless steel provides superior corrosion resistance, which helps maintain vacuum purity over the long term.

Pillar 3: Managing Thermal Loads with Cooling

The extreme heat generated inside the furnace can cause the outer shell to expand and warp. This thermal deformation can compromise the integrity of seals, leading to vacuum leaks.

To prevent this, the shell is almost always constructed with an integrated cooling system. This is typically a double-walled design, or a "jacket," through which cooling water or air is constantly circulated.

This cooling jacket actively removes heat from the outer shell, keeping its temperature stable and ensuring all sealing surfaces remain dimensionally accurate.

Operational and Environmental Requirements

Beyond the physical design, the furnace's operating environment and internal cleanliness are critical requirements for performance and safety.

The External Environment

A vacuum furnace must be operated in a workspace free of flammable, explosive, or corrosive gases. These substances pose a significant safety risk and can be drawn into the furnace if a minor leak develops, contaminating the process and damaging the equipment.

Internal Cleanliness and Material Handling

The internal furnace chamber must be kept impeccably clean. Any residue, oil, or debris left inside will "outgas" as the furnace heats up, releasing vapors that contaminate the vacuum and prevent it from reaching the required low pressure.

For this reason, direct injection of liquids or molten metals into the hot chamber is strictly prohibited. This can cause a sudden, violent vaporization that creates a dangerous pressure spike and can severely damage the furnace interior.

Understanding the Trade-offs

Choosing and maintaining a furnace shell involves balancing cost, performance, and operational discipline.

Material Choice: Carbon Steel vs. Stainless Steel

Carbon steel is less expensive initially but is susceptible to rust. Rust on a sealing surface can easily create a vacuum leak. Stainless steel costs more but offers excellent corrosion resistance, ensuring a cleaner vacuum environment and longer-lasting seal integrity.

The Consequence of Inadequate Cooling

Failing to maintain proper coolant flow is a common operational mistake. An overheating shell will lead to warped flanges and failing O-ring seals, resulting in persistent and hard-to-find vacuum leaks that disrupt production.

The Critical Impact of Leaks

Even a microscopic leak is a major failure. It prevents the system from reaching its ultimate vacuum level and, more importantly, continuously introduces atmospheric gases like oxygen and nitrogen into the chamber. For sensitive processes like brazing or heat treating, this contamination can lead to oxidation and complete failure of the product batch.

Making the Right Choice for Your Goal

Your priorities for the furnace shell should align with your primary operational objective.

- If your primary focus is process purity and long-term reliability: Invest in a stainless steel shell and a robust, well-monitored cooling system.

- If your primary focus is operational uptime and maintenance: Implement strict internal cleanliness protocols and a regular schedule for leak-checking seals and verifying cooling system performance.

- If your primary focus is achieving consistent product quality: Regularly monitor the furnace's ultimate vacuum level and leak-up rate, as these are direct indicators of the shell's sealing integrity.

Ultimately, the sealed furnace shell is the foundation upon which every successful vacuum processing application is built.

Summary Table:

| Requirement | Key Details |

|---|---|

| Airtight Sealing | Hermetic welds, O-rings (e.g., Viton, Kalrez) for removable parts |

| Structural Strength | Thick carbon or stainless steel to withstand atmospheric pressure |

| Cooling System | Double-walled jacket with water/air circulation to prevent thermal deformation |

| Operational Environment | Free from flammable, explosive, or corrosive gases |

| Internal Cleanliness | No residue or liquids to avoid outgassing and contamination |

Upgrade your lab's thermal processing with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-performance furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing