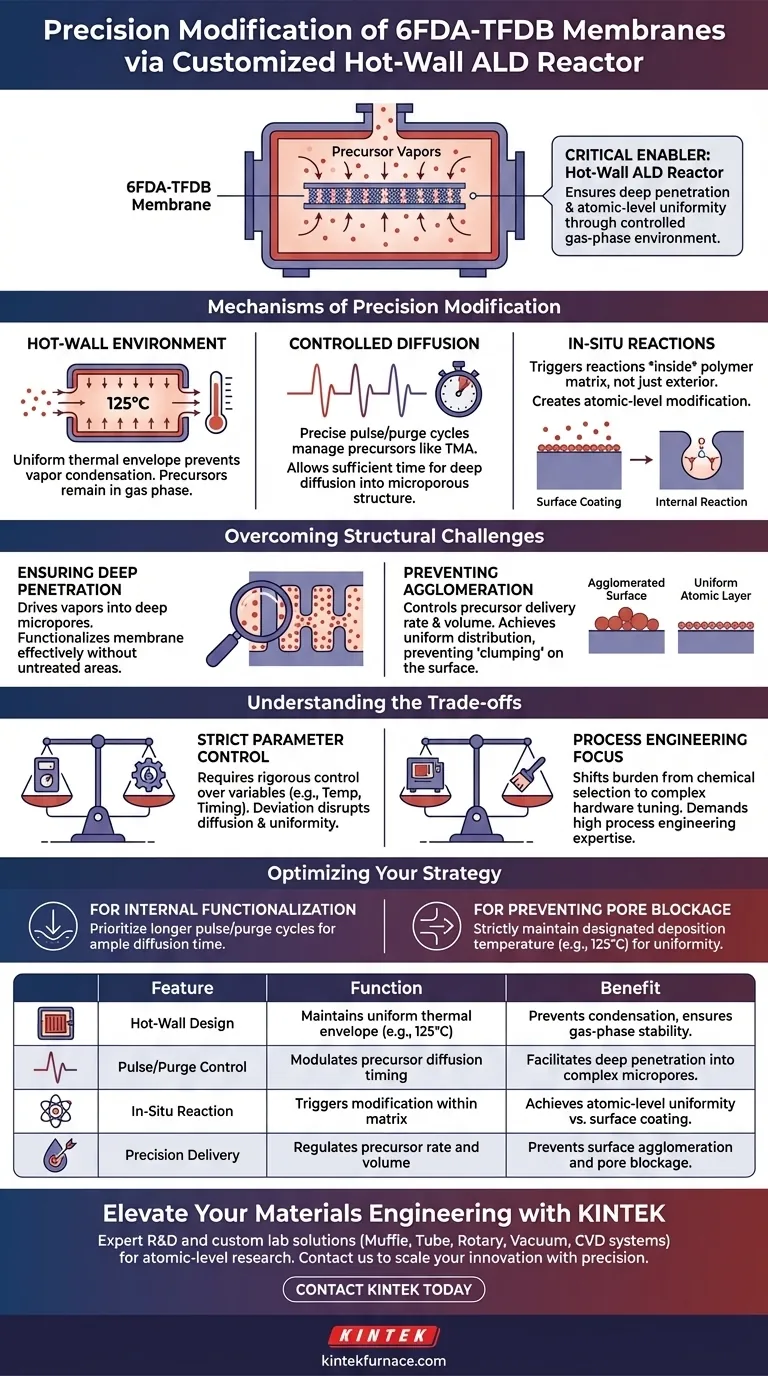

A customized hot-wall Atomic Layer Deposition (ALD) reactor serves as the critical enabler for the precise chemical modification of 6FDA-TFDB membranes. By maintaining a strictly controlled gas-phase environment, the reactor regulates deposition temperatures and pulse/purge cycles to ensure precursor vapors penetrate the polymer deeply. This apparatus allows for in-situ reactions within the microporous structure, distinguishing high-quality modification from superficial surface coatings.

The core value of the hot-wall ALD reactor is its ability to facilitate atomic-level uniformity. It ensures chemical precursors react inside the polymer matrix rather than accumulating on the exterior, effectively preventing surface agglomeration.

Mechanisms of Precision Modification

The Role of the Hot-Wall Environment

The primary function of the "hot-wall" design is to create a uniform thermal envelope around the sample. By maintaining specific deposition temperatures, such as 125°C, the reactor prevents precursor vapors from condensing on the chamber walls. This ensures that the chemical agents remain in the gas phase, directed entirely toward interacting with the membrane.

Controlling Precursor Diffusion

The reactor allows for the precise management of pulse and purge cycles. This control is vital for handling precursors like trimethylaluminum. By modulating these cycles, the system gives the vapor sufficient time to diffuse into the complex microporous structure of the 6FDA-TFDB polymer.

Facilitating In-Situ Reactions

Unlike simple coating methods, this reactor setup is designed to trigger reactions within the material itself. The controlled environment enables in-situ reactions, meaning the chemical modification occurs internally across the pore surfaces rather than just on the exterior face of the membrane.

Overcoming Structural Challenges

Ensuring Deep Microporous Penetration

One of the most significant challenges in modifying 6FDA-TFDB membranes is reaching the internal surface area. The customized reactor drives precursor vapors into the deep micropores. This penetration is essential for functionalizing the membrane effectively without leaving internal areas untreated.

Preventing Surface Agglomeration

A common failure point in membrane modification is the "clumping" of materials on the surface. The ALD reactor’s precision prevents this surface agglomeration. By controlling the rate and volume of precursor delivery, it achieves a uniform distribution at the atomic level, keeping the membrane's surface clean and porous.

Understanding the Trade-offs

The Necessity of Strict Parameter Control

While this method offers superior quality, it requires rigorous control over variables. Deviation from the optimal temperature (e.g., 125°C) or timing in pulse/purge cycles can disrupt the diffusion process. The system relies on exact calibration to avoid incomplete penetration or unwanted vapor phase reactions.

Complexity vs. Simplicity

Using a customized hot-wall reactor is inherently more complex than standard dip-coating or ambient gas treatments. It shifts the burden of quality from chemical selection to process engineering. The hardware must be specifically tuned to the thermal and kinetic properties of both the 6FDA-TFDB polymer and the chosen precursor.

Optimizing Your Membrane Modification Strategy

To leverage a hot-wall ALD reactor effectively, you must align the process parameters with your specific structural goals.

- If your primary focus is internal functionalization: Prioritize longer pulse/purge cycles to allow the precursor vapors ample time to diffuse deep into the microporous structure before reacting.

- If your primary focus is preventing pore blockage: Strictly maintain the designated deposition temperature (e.g., 125°C) to ensure atomic-level uniformity and avoid surface agglomeration that could choke flow.

Success in modifying 6FDA-TFDB membranes lies in using the reactor not just as a coating tool, but as a mechanism for controlled, internal structural engineering.

Summary Table:

| Feature | Function in Membrane Modification | Benefit for 6FDA-TFDB |

|---|---|---|

| Hot-Wall Design | Maintains uniform thermal envelope (e.g., 125°C) | Prevents condensation and ensures gas-phase stability |

| Pulse/Purge Control | Modulates precursor diffusion timing | Facilitates deep penetration into complex micropores |

| In-Situ Reaction | Triggers chemical modification within the matrix | Achieves atomic-level uniformity vs. surface coating |

| Precision Delivery | Regulates precursor rate and volume | Prevents surface agglomeration and pore blockage |

Elevate Your Materials Engineering with KINTEK

Precise chemical modification requires more than just standard equipment; it demands a partner who understands the nuances of thermal and kinetic process engineering. KINTEK provides high-performance, customizable lab solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, designed to meet the rigorous demands of atomic-level research.

Whether you are functionalizing 6FDA-TFDB membranes or developing next-generation microporous structures, our expert R&D and manufacturing teams are here to help you scale your innovation with precision and reliability.

Ready to optimize your deposition process? Contact KINTEK today to discuss your custom project.

Visual Guide

References

- Xiuling Chen, Nanwen Li. Atomically distributed Al-F3 nanoparticles towards precisely modulating pore size of carbon membranes for gas separation. DOI: 10.1038/s41467-024-54275-1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- Why is NaCl used in WTe2 CVD synthesis? Enhance Crystal Growth with Salt-Assisted Flux

- Why is Ar/H2 Flow Control Critical for V2O5 Nanosheet CVD? Master Redox Potential and Morphology

- How do IoT gas sensors and Autoencoders contribute to CVD furnace safety? Enhance Pipeline Integrity and Monitoring

- What is Chemical Vapor Deposition (CVD) and what is it used for? Unlock High-Performance Thin Films

- What are the drawbacks of CVD coatings? Understand the limitations and trade-offs for your application.

- How do industrial-grade vacuum CVD reactors achieve precise precursor control? Mastering Nitrogen-Doped Graphene Growth

- What drives the precursor generation and decomposition in CVD? Master Thermodynamics and Kinetics for Superior Film Growth

- What nanomaterials can be synthesized using CVD furnaces? Unlock Versatile Nanoscale Material Creation