At their core, PECVD and CVD are both chemical vapor deposition processes, but they differ fundamentally in how they energize the chemical reactions required for film growth. Conventional CVD relies on high thermal energy (heat) to break down precursor gases. In contrast, PECVD (Plasma-Enhanced Chemical Vapor Deposition) uses an electrically-excited plasma to achieve the same result at significantly lower temperatures.

The choice between CVD and PECVD is a critical engineering decision driven by a single factor: the energy source. Using heat (CVD) versus plasma (PECVD) dictates everything from the materials you can use to the final properties of the film and the overall cost of the process.

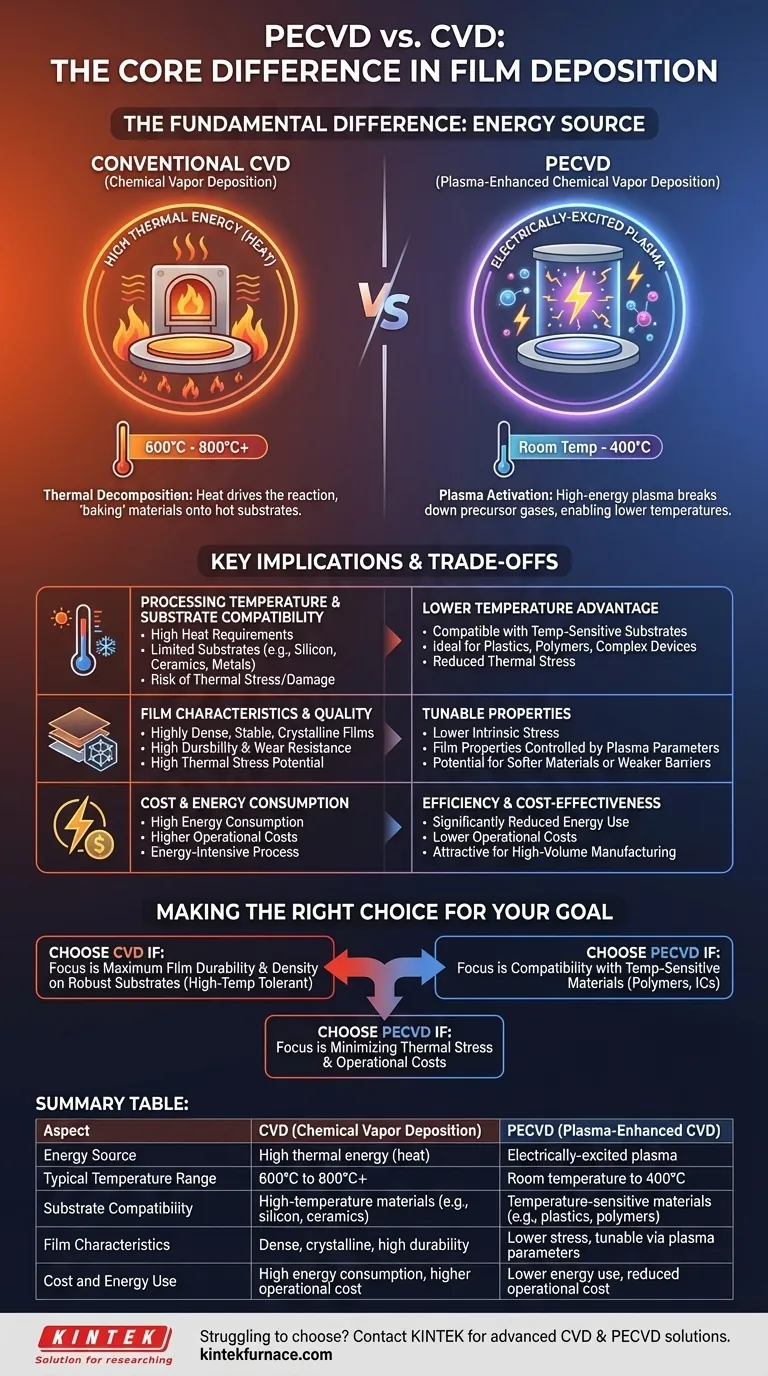

The Fundamental Difference: Heat vs. Plasma

The method used to supply energy to the precursor gases is the defining distinction between these two technologies. This choice has cascading effects on the entire deposition process.

How Conventional CVD Works: Thermal Decomposition

Conventional CVD operates on a simple principle: heat drives the reaction. Precursor gases are introduced into a chamber where the substrate is heated to very high temperatures, typically between 600°C and 800°C, and sometimes much higher.

This intense thermal energy causes the gas molecules to decompose and react on the hot substrate surface, gradually building up a thin film. It can be thought of as precisely "baking" a new material layer onto a component.

How PECVD Works: Plasma Activation

PECVD bypasses the need for extreme heat by using plasma—an ionized gas containing high-energy electrons, ions, and free radicals. An electrical field is applied to the precursor gas, creating this plasma.

These high-energy particles collide with the precursor gas molecules, breaking them apart and creating the reactive species needed for deposition. Because the energy comes from the plasma itself, not from heating the substrate, the process can run at much lower temperatures, often from room temperature up to around 350-400°C.

Key Implications of the Energy Source

The difference in energy source is not merely academic. It creates dramatic and practical differences in process capability, material compatibility, and cost.

Processing Temperature and Substrate Compatibility

This is the most significant consequence. CVD's high thermal requirements limit its use to substrates that can withstand extreme temperatures, such as silicon wafers, ceramics, or certain metals.

PECVD's low-temperature nature makes it compatible with a vastly wider range of temperature-sensitive substrates. This includes plastics, polymers, and complex electronic devices with pre-existing layers that would be damaged or destroyed by CVD's heat.

Film Quality and Thermal Stress

The high heat of CVD can induce significant thermal stress in both the film and the substrate, potentially leading to cracking or warping. However, the high temperature can also produce highly dense, stable, and crystalline films.

PECVD deposits films with much lower intrinsic stress, which is critical for delicate structures. The film's properties are controlled by plasma parameters rather than temperature alone, offering a different set of variables for tuning film characteristics.

Cost and Energy Consumption

Heating a process chamber to over 600°C requires a substantial amount of energy, making conventional CVD a relatively high-cost, energy-intensive process.

By operating at lower temperatures, PECVD significantly reduces energy consumption and, consequently, operational costs. This efficiency makes it an attractive option for high-volume manufacturing.

Understanding the Trade-offs

Neither technology is universally superior. The optimal choice depends on balancing the inherent strengths and weaknesses of each method against the project's specific requirements.

The Limitations of PECVD

While versatile, PECVD films can present certain compromises. The resulting materials may be softer or have less wear resistance than their high-temperature CVD counterparts.

Furthermore, some PECVD films may exhibit weaker barrier performance compared to films deposited by other methods. The process can also involve halogenated precursor gases, which require careful handling due to potential health and environmental concerns.

The Constraints of CVD

The primary drawback of CVD is its high thermal budget. This immediately excludes its use for a growing number of modern applications involving polymers and advanced electronics.

The high heat not only limits substrate choice but also increases the risk of damaging the components being coated. Finally, the higher energy consumption translates directly to higher production costs.

Making the Right Choice for Your Goal

Selecting the correct deposition method requires a clear understanding of your primary objective. Your material, performance target, and budget will guide your decision.

- If your primary focus is maximum film durability on a robust substrate: CVD is often the superior choice for creating highly dense and crystalline films when the substrate can tolerate extreme heat.

- If your primary focus is compatibility with temperature-sensitive materials: PECVD is the definitive solution for depositing films on polymers, plastics, or complex integrated circuits that cannot survive high temperatures.

- If your primary focus is minimizing thermal stress and operational cost: PECVD's low-temperature, energy-efficient process reduces the risk of thermal damage and lowers production expenses.

Ultimately, understanding the energy source—thermal versus plasma—is the key to selecting the deposition method that aligns with your material constraints and performance goals.

Summary Table:

| Aspect | CVD (Chemical Vapor Deposition) | PECVD (Plasma-Enhanced CVD) |

|---|---|---|

| Energy Source | High thermal energy (heat) | Electrically-excited plasma |

| Typical Temperature Range | 600°C to 800°C+ | Room temperature to 400°C |

| Substrate Compatibility | High-temperature materials (e.g., silicon, ceramics) | Temperature-sensitive materials (e.g., plastics, polymers) |

| Film Characteristics | Dense, crystalline, high durability | Lower stress, tunable via plasma parameters |

| Cost and Energy Use | High energy consumption, higher operational cost | Lower energy use, reduced operational cost |

Struggling to choose the right deposition method for your lab? KINTEK specializes in advanced high-temperature furnace solutions, including CVD and PECVD systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—whether you're working with robust substrates or temperature-sensitive materials. Contact us today to enhance your lab's efficiency and achieve precise film deposition results!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is PECVD specification? A Guide to Choosing the Right System for Your Lab

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition