At its core, modern dental furnace precision comes from microprocessor-based control, which allows for the independent and highly accurate programming of every critical variable in the sintering cycle. This digital oversight governs the exact timing, temperature, heating and cooling rates, and internal atmosphere, ensuring that complex, material-specific protocols are executed flawlessly every time.

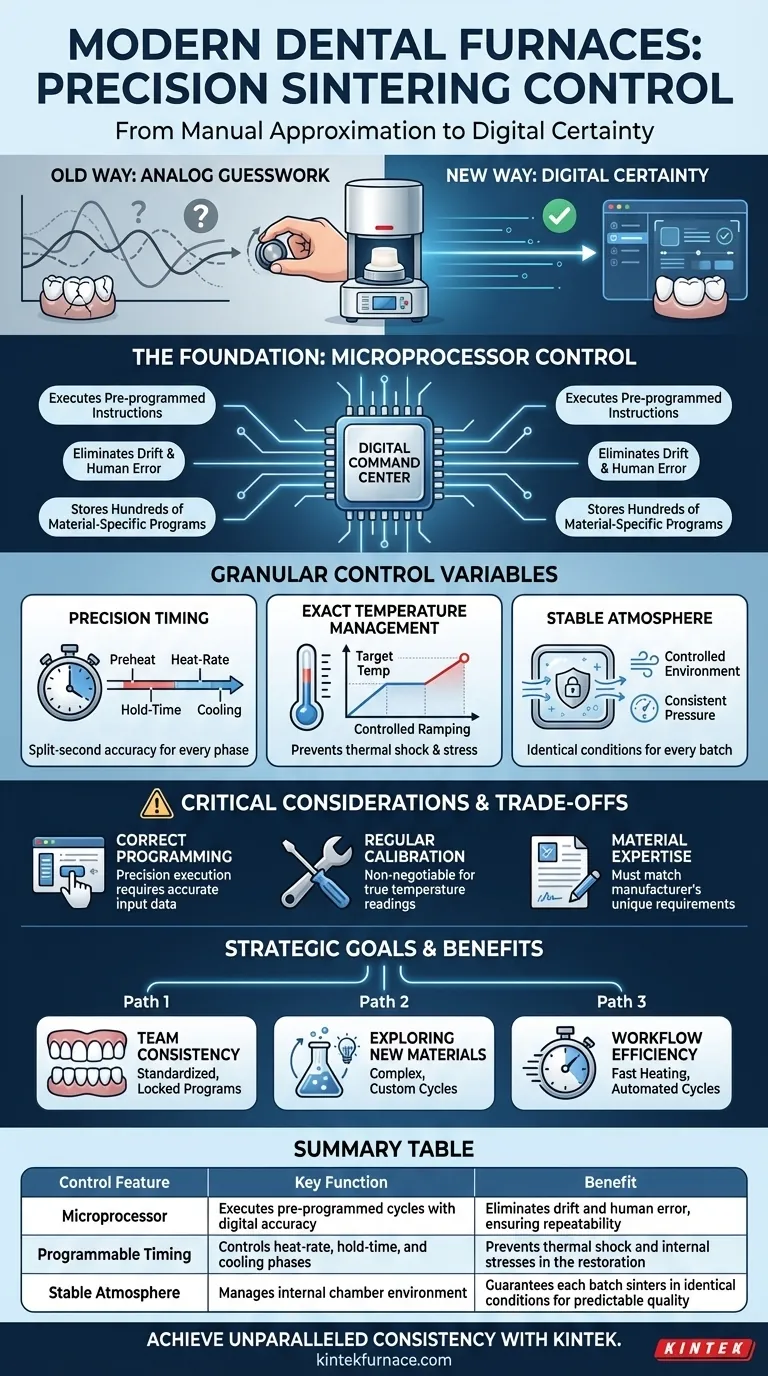

The fundamental shift is from manual approximation to digital certainty. By replacing analog guesswork with programmable microprocessors, modern furnaces transform the sintering process into a repeatable, scientific procedure that produces consistent, high-quality dental restorations.

The Foundation of Control: The Microprocessor

The "brain" of a modern dental furnace is its integrated microprocessor. This component is solely responsible for translating a user's desired settings into the physical operations of the heating elements and chamber controls.

The Digital Command Center

A microprocessor acts as the central command unit, executing pre-programmed instructions with absolute precision. Unlike older analog systems, it doesn't drift or lose accuracy over time, ensuring that the 100th firing cycle is identical to the first.

Programmability and Memory

Modern furnaces can often store hundreds of unique sintering programs. This allows a dental lab to create and save specific cycles for every type of ceramic material they use—from zirconia and opaquer porcelains to shoulder and glaze firings—and recall them with the touch of a button.

Deconstructing the Sintering Cycle: Granular Control

Precision isn't about one single feature; it's about the furnace's ability to manage multiple variables independently throughout the entire heating and cooling process.

Precision Timing

Every phase of the cycle can be programmed down to the split second. This includes the initial preheating/drying phase, the rate of temperature increase (heat-rate), the duration at peak temperature (hold-time), and the cooling phase.

Exact Temperature Management

The furnace can be programmed for specific target temperatures with high accuracy. More importantly, it controls the rate at which it reaches that temperature. This precise ramping is essential for preventing thermal shock and internal stresses in the restoration.

Stable Atmosphere and Pressure

For consistent results, the environment inside the firing chamber must be perfectly controlled. Modern furnaces manage the internal atmosphere and pressure to ensure that each batch of restorations sinters in identical conditions, leading to predictable stability and quality.

Understanding the Trade-offs

This level of precision offers incredible advantages, but it's crucial to understand the context in which it operates. The furnace is a tool that executes instructions perfectly, but it relies on correct input.

The Necessity of Correct Programming

A furnace's precision is only as good as the program it's running. Selecting an incorrect program or entering the wrong parameters for a specific material will still lead to a poor outcome, no matter how accurately the furnace executes the flawed instructions.

Calibration is Non-Negotiable

Automated calibration is a key feature, but it is not optional. Regular calibration ensures the furnace's temperature sensors are reporting correctly. A miscalibrated furnace provides a false sense of security, executing a program with precision but at the wrong actual temperature.

Material-Specific Requirements

The furnace's adaptability to various ceramic materials is a major strength. However, the user must still possess the expertise to know the exact sintering requirements for each material. The furnace cannot compensate for a program that doesn't match the material manufacturer's specifications.

Making the Right Choice for Your Goal

By understanding these control mechanisms, you can leverage your furnace to meet specific clinical and operational objectives.

- If your primary focus is consistency across a team: Use the furnace's memory to create and lock standardized, named programs for each material, ensuring every technician achieves the same result.

- If your primary focus is exploring new materials: Rely on the granular programmability to precisely match the complex heating and cooling cycles recommended by the material's manufacturer.

- If your primary focus is workflow efficiency: Utilize the fast heating rates and automated "set-and-forget" cycles to minimize hands-on time and increase your lab's overall throughput.

By mastering these precise controls, you transform the dental furnace from a simple oven into a predictable manufacturing tool for exceptional restorations.

Summary Table:

| Control Feature | Key Function | Benefit |

|---|---|---|

| Microprocessor | Executes pre-programmed cycles with digital accuracy | Eliminates drift and human error, ensuring repeatability |

| Programmable Timing | Controls heat-rate, hold-time, and cooling phases | Prevents thermal shock and internal stresses in the restoration |

| Stable Atmosphere | Manages internal chamber environment | Guarantees each batch sinters in identical conditions for predictable quality |

Ready to achieve unparalleled consistency and quality in your dental lab?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides dental laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet your unique sintering requirements.

Contact us today to discover how a KINTEK furnace can become the predictable, precision manufacturing tool your lab needs for exceptional restorations.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations