Industrial electric heating chamber furnaces guarantee process assurance by creating a precise, stable high-temperature environment, typically maintained at 900 degrees Celsius for ASTM A36 steel. This rigorous temperature control provides the constant energy required for carbon atoms to overcome diffusion resistance, while sustained heat preservation ensures the carburized layer achieves the specified depth and microstructural transformation.

Core Insight: The carburization of ASTM A36 steel is not merely about reaching a temperature; it is about maintaining specific energy levels over time. Electric chamber furnaces solve the problem of diffusion resistance by delivering the constant thermal energy required to drive carbon atoms into the steel matrix.

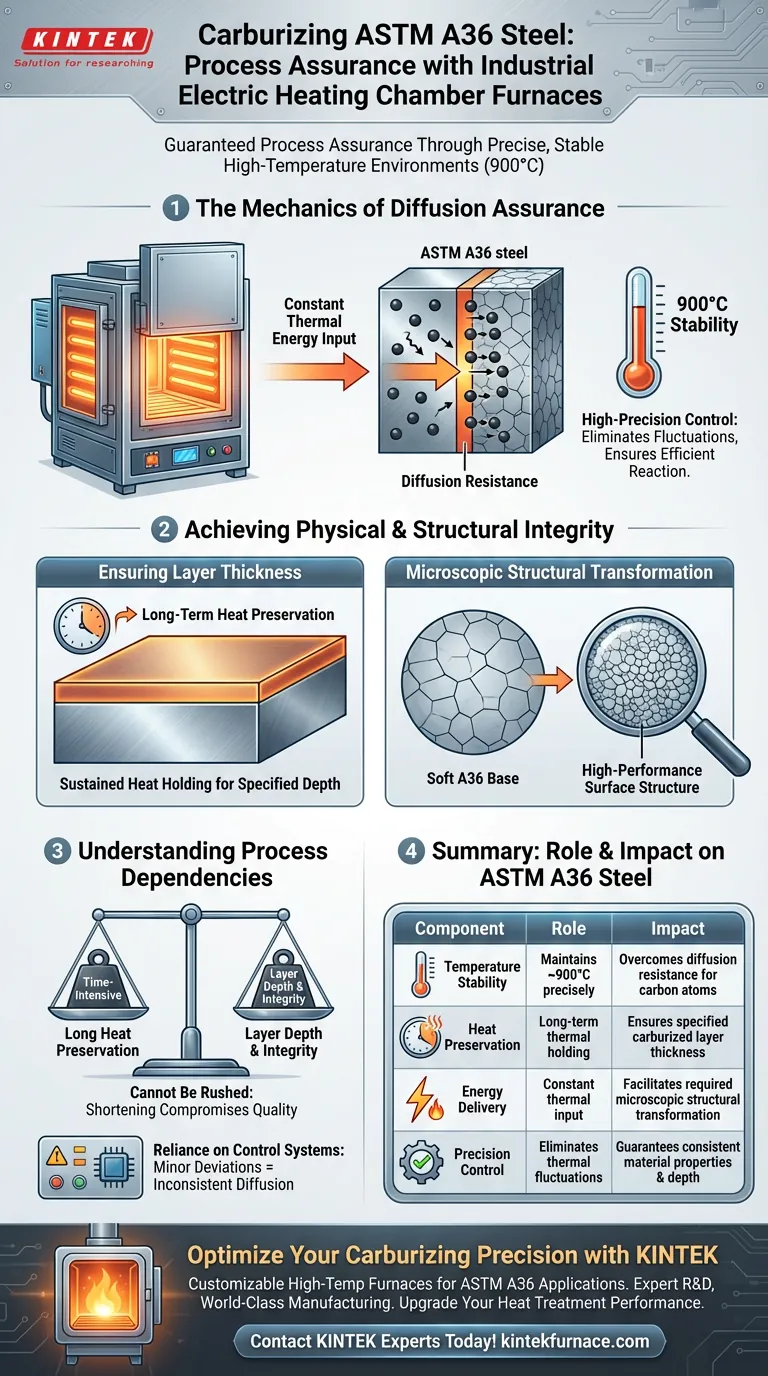

The Mechanics of Diffusion Assurance

Overcoming Diffusion Resistance

The primary challenge in carburizing steel is physical resistance to carbon entry. Carbon atoms require significant, uninterrupted energy to penetrate the surface of the steel.

Electric heating chamber furnaces provide this by ensuring the thermal energy input is constant. This allows the carbon atoms to consistently overcome diffusion resistance and migrate into the material.

Stability at Critical Temperatures

For ASTM A36 steel, the process requires a stable environment of approximately 900 degrees Celsius.

Fluctuations in temperature can interrupt the energy supply needed for the reaction. The high-precision control of these furnaces eliminates such variables, maintaining the exact environment required for the chemical reaction to proceed efficiently.

Achieving Physical and Structural Integrity

Ensuring Layer Thickness

Creating a durable wear layer is a function of time and temperature stability.

Through long-term heat preservation, the furnace allows the process to continue until the carburized layer reaches its intended physical thickness. Without this sustained heat holding capability, the hardened layer would be too thin to be effective.

Microscopic Structural Transformation

The quality of the heat treatment is determined at the microscopic level.

Beyond simple depth, the furnace's ability to hold heat ensures the steel undergoes the necessary microscopic structural transformation. This phase change is critical for converting the soft A36 base material into a surface capable of high performance.

Understanding Process Dependencies

The Trade-off of Time

While electric chamber furnaces provide precision, the "long-term heat preservation" required for deep carburization is time-intensive.

Operators must accept that achieving the intended physical thickness cannot be rushed. Shortening the heat preservation cycle will directly compromise the depth and integrity of the carburized layer.

Reliance on Control Systems

The process assurance described here is entirely dependent on the furnace's temperature control systems.

If the high-precision control fails, the "constant energy" required to overcome diffusion resistance is lost. Even minor deviations at 900°C can result in inconsistent diffusion and unpredictable material properties.

Making the Right Choice for Your Goal

To maximize the effectiveness of your carburizing process, align your furnace operation with your specific metallurgical targets:

- If your primary focus is Layer Depth: Prioritize the furnace's heat preservation capabilities to ensure the cycle is held long enough for deep carbon diffusion.

- If your primary focus is Structural Consistency: Prioritize high-precision temperature control to guarantee constant energy delivery and uniform microscopic transformation.

True process assurance comes from understanding that the furnace is not just a heat source, but a precision instrument for managing atomic diffusion.

Summary Table:

| Process Component | Role in Carburizing | Impact on ASTM A36 Steel |

|---|---|---|

| Temperature Stability | Maintains ~900°C precisely | Overcomes diffusion resistance for carbon atoms |

| Heat Preservation | Long-term thermal holding | Ensures specified carburized layer thickness |

| Energy Delivery | Constant thermal input | Facilitates required microscopic structural transformation |

| Precision Control | Eliminates thermal fluctuations | Guarantees consistent material properties and depth |

Optimize Your Carburizing Precision with KINTEK

Don't let inconsistent thermal cycles compromise your material integrity. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically engineered to overcome diffusion resistance and ensure deep, uniform carburized layers.

Backed by expert R&D and world-class manufacturing, our lab and industrial high-temp furnaces are fully customizable to meet your unique metallurgical standards. Whether you are focusing on layer depth or microscopic consistency, our high-precision control systems deliver the process assurance your ASTM A36 applications demand.

Ready to upgrade your heat treatment performance? Contact our experts today to find your custom furnace solution!

Visual Guide

References

- The effect of carbonate energizer on pack carburizing ASTM A36 steel. DOI: 10.30574/gjeta.2025.23.2.0145

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How do high-temperature furnaces facilitate ZnZrOx and InZrOx catalysts? Optimize Your Solid Solution Synthesis

- What are the safety precautions when using a box type electric furnace? Ensure Operator and Equipment Protection

- What role do muffle furnaces play in pharmaceutical research and development? Essential for Quality Control and Innovation

- What are the primary functions of industrial high-temperature muffle or tube furnaces in the sintering of PCEC?

- Why was the muffle furnace initially developed? To Ensure Purity in High-Temperature Processing

- What are the key differences between a muffle furnace and a vacuum furnace? Choose the Right Furnace for Your Lab

- What are the installation and maintenance benefits of electric furnaces? Achieve Simpler, Lower-Cost Heating

- How does a muffle furnace control the atmosphere around the sample? Achieve Precise Material Processing