At its core, an induction furnace achieves faster melting times because it heats the metal directly and internally. Unlike traditional furnaces that heat a container or the surrounding air first, induction uses a powerful magnetic field to generate heat instantly within the metal itself, eliminating thermal lag and dramatically accelerating the process.

The fundamental advantage of induction is the shift from indirect, external heating to direct, internal heating. This principle is the source of its exceptional speed, energy efficiency, and ability to improve metal quality.

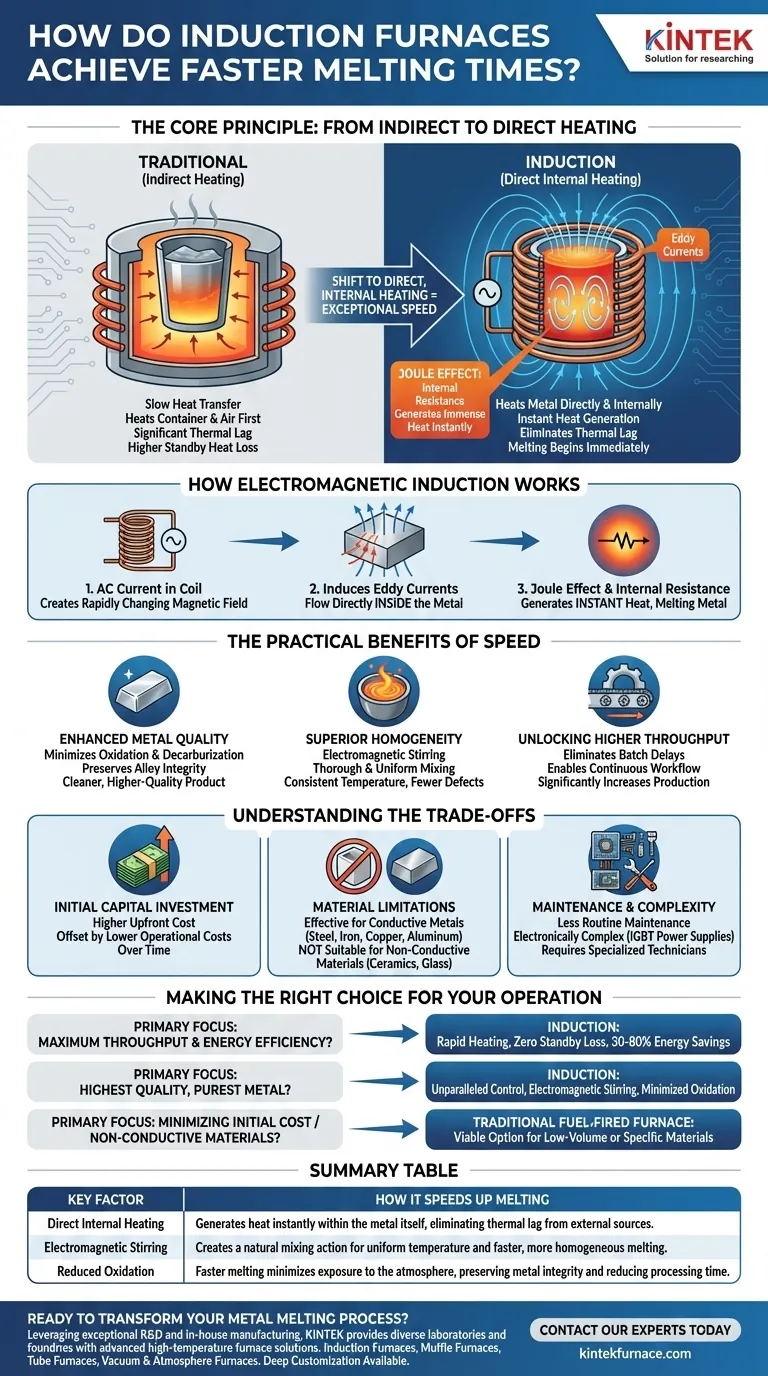

The Core Principle: From Indirect to Direct Heating

Traditional furnaces operate like a conventional oven, slowly transferring heat from an external source (like burning fuel or electric elements) to the metal. Induction heating fundamentally changes this dynamic.

How Electromagnetic Induction Works

An induction furnace uses a coil of conductive material, typically copper, through which a high-frequency alternating current (AC) is passed. This creates a powerful, rapidly changing magnetic field around the coil. When conductive material like metal is placed within this field, it induces electrical currents—known as eddy currents—to flow directly inside the metal.

The Power of Internal Resistance

The metal's natural resistance to the flow of these eddy currents generates immense heat almost instantaneously. This phenomenon, known as the Joule effect, is the primary source of melting. The heat is generated from the inside out, not the outside in.

Eliminating Thermal Lag

Because the heat is generated within the workpiece, there is no need to wait for a crucible, chamber, or surrounding air to heat up first. This eliminates thermal lag and standby heat loss, allowing melting to begin the moment the system is activated. Some systems can bring metal to over 2,000°F in under a second.

The Practical Benefits of Speed

This rapid, direct heating method delivers significant operational advantages beyond just melting faster.

Enhanced Metal Quality

The speed of induction heating drastically reduces the time the molten metal is exposed to the atmosphere. This minimizes oxidation and other reactions like decarburization, preserving the alloy's integrity and resulting in a cleaner, higher-quality final product.

Superior Homogeneity

The strong magnetic fields also create a natural electromagnetic stirring action within the molten bath. This ensures the alloy is mixed thoroughly and uniformly, leading to consistent temperature, better scum removal, and castings with fewer impurities or defects like porosity.

Unlocking Higher Throughput

Fast melting and cooling cycles eliminate the delays associated with batch processing in traditional furnaces. This enables a continuous workflow, allowing operations to be performed directly on the factory floor and significantly increasing production throughput.

Understanding the Trade-offs

While highly effective, induction technology is not a universal solution. Understanding its limitations is key to making an informed decision.

Initial Capital Investment

Induction furnaces often represent a higher upfront capital cost compared to simpler, fuel-fired furnace systems. However, this is frequently offset by lower operational costs over time.

Material Limitations

The core principle of induction relies on electrical conductivity. The process is highly effective for conductive metals like steel, iron, copper, and aluminum but is not suitable for non-conductive materials like ceramics or glass.

Maintenance and Complexity

While they require less routine maintenance and no fuel handling, modern induction systems are electronically complex. Repairing IGBT power supplies and control systems requires specialized technicians, which can be a different type of operational dependency compared to the mechanical nature of older furnaces.

Making the Right Choice for Your Operation

Choosing the right melting technology depends entirely on your primary operational goals.

- If your primary focus is maximum throughput and energy efficiency: Induction is the clear leader due to its rapid heating, zero standby heat loss, and potential for 30-80% energy savings.

- If your primary focus is producing the highest quality, purest metal: The speed and electromagnetic stirring of induction offer unparalleled control over oxidation and alloy homogeneity.

- If your primary focus is minimizing initial cost for low-volume or varied materials: A traditional fuel-fired furnace might remain a viable option, especially if non-conductive materials are involved.

By understanding the principles of direct internal heating, you can leverage the right technology to meet your specific production demands.

Summary Table:

| Key Factor | How It Speeds Up Melting |

|---|---|

| Direct Internal Heating | Generates heat instantly within the metal itself, eliminating thermal lag from external sources. |

| Electromagnetic Stirring | Creates a natural mixing action for uniform temperature and faster, more homogeneous melting. |

| Reduced Oxidation | Faster melting minimizes exposure to the atmosphere, preserving metal integrity and reducing processing time. |

Ready to transform your metal melting process with the speed and precision of induction heating?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and foundries with advanced high-temperature furnace solutions. Our product line, including Induction Furnaces, Muffle Furnaces, Tube Furnaces, and Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet your unique production requirements—whether you prioritize maximum throughput, superior metal quality, or energy efficiency.

Contact our experts today to discuss how a KINTEK induction furnace can accelerate your operations and enhance your final product quality.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications