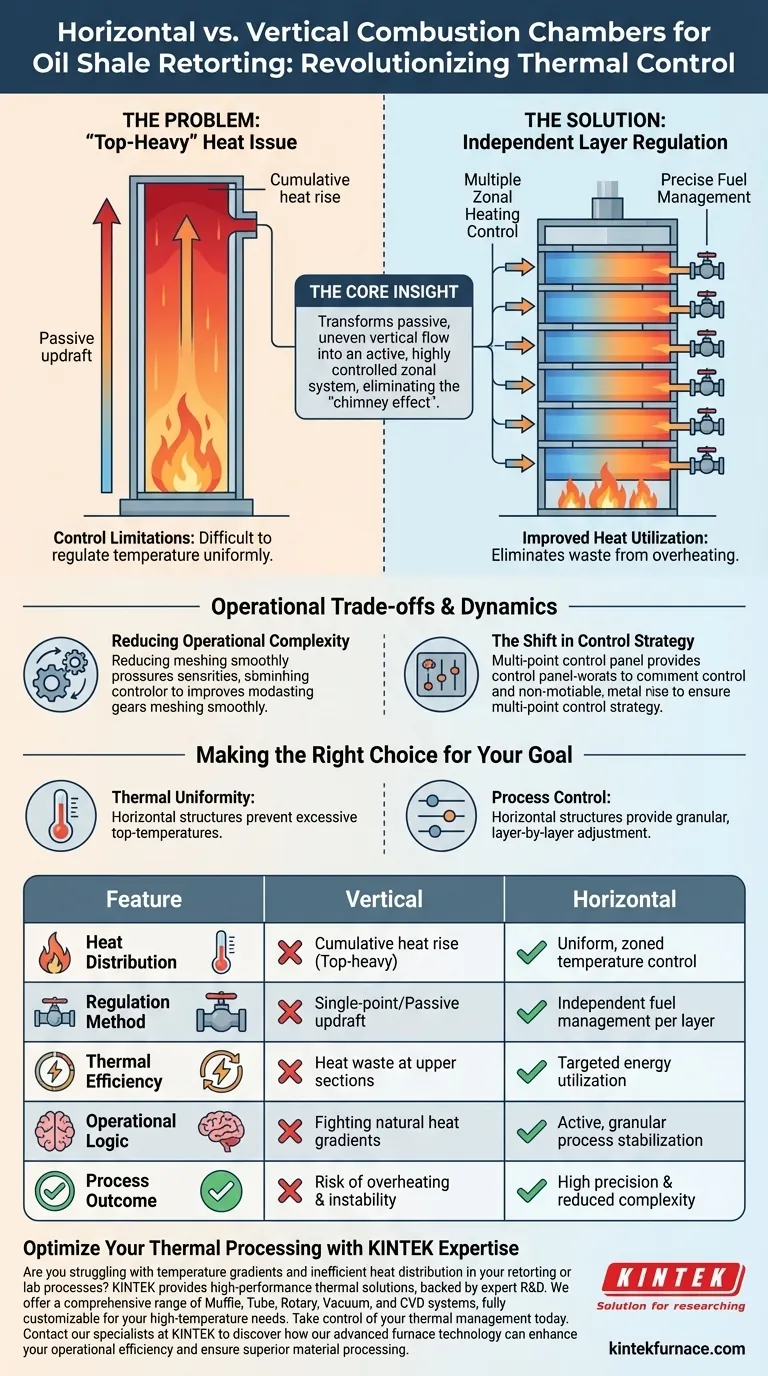

Horizontal combustion chamber structures revolutionize thermal control by enabling independent temperature regulation at specific heights within the oil shale retort. Unlike vertical structures, which suffer from cumulative heat rise, horizontal designs allow operators to adjust fuel consumption for each individual combustion layer, ensuring precise thermal management and preventing overheating at the top of the chamber.

The Core Insight By segmenting the heating wall into independent horizontal layers, this design eliminates the "chimney effect" inherent in vertical channels. It transforms the heating process from a passive, uneven vertical flow into an active, highly controlled zonal system.

The Problem with Vertical Structures

The "Top-Heavy" Heat Issue

Traditional vertical channels often face significant thermal imbalances.

Because heat naturally rises, the temperature at the top of a vertical combustion chamber tends to become excessively high.

Control Limitations

This natural thermal gradient makes it extremely difficult to regulate temperature distribution uniformly.

Operators often struggle to cool the top section without disrupting the heat required at the bottom, leading to inefficient processing.

How Horizontal Structures Solve the Problem

Independent Layer Regulation

Horizontal combustion chamber structures are designed to break the heating wall into distinct, manageable zones.

This allows for the independent regulation of the temperature distribution at different heights.

Precise Fuel Management

The system achieves this control by regulating the fuel consumption of each individual combustion layer.

Operators can increase fuel in cooler zones and decrease it in hotter zones, creating a tailored heat profile.

Improved Heat Utilization

By eliminating the waste associated with overheating the top of the chamber, the system utilizes heat more effectively.

Energy is directed exactly where it is needed, rather than accumulating where it causes damage or inefficiency.

Operational Trade-offs and Dynamics

Reducing Operational Complexity

While moving to a segmented system might sound more complex mechanically, the source indicates that it actually reduces operational complexity.

This is because the difficulty of fighting against the physics of a vertical heat column is removed.

The Shift in Control Strategy

The trade-off involves moving from a single-point control strategy to a multi-point strategy.

Success relies on the operator's ability to monitor and adjust the fuel consumption for multiple layers rather than managing a single updraft.

Making the Right Choice for Your Goal

When evaluating retort design, the choice between vertical and horizontal structures depends on your need for precision.

- If your primary focus is Thermal Uniformity: Horizontal structures are superior because they prevent the excessive top-temperatures common in vertical designs.

- If your primary focus is Process Control: Horizontal structures provide the granular ability to adjust fuel consumption layer-by-layer, simplifying the stabilization of the retort.

Horizontal layering turns temperature distribution into a manageable variable rather than a difficult constraint.

Summary Table:

| Feature | Vertical Combustion Chambers | Horizontal Combustion Chambers |

|---|---|---|

| Heat Distribution | Cumulative heat rise (Top-heavy) | Uniform, zoned temperature control |

| Regulation Method | Single-point/Passive updraft | Independent fuel management per layer |

| Thermal Efficiency | Heat waste at upper sections | Targeted energy utilization |

| Operational Logic | Fighting natural heat gradients | Active, granular process stabilization |

| Process Outcome | Risk of overheating & instability | High precision & reduced complexity |

Optimize Your Thermal Processing with KINTEK Expertise

Are you struggling with temperature gradients and inefficient heat distribution in your retorting or lab processes? KINTEK provides high-performance thermal solutions designed to meet the most demanding industrial and research standards. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be fully customized for your unique high-temperature needs.

Take control of your thermal management today. Contact our specialists at KINTEK to discover how our advanced furnace technology can enhance your operational efficiency and ensure superior material processing.

Visual Guide

References

- Lixin Zhao, Luwei Pan. Numerical Study of the Combustion-Flow-Thermo-Pyrolysis Process in an Innovative Externally Heated Oil Shale Retort. DOI: 10.3390/sym17071055

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does the ramp rate affect LDO properties? Master Rapid Thermal Control for 69% More Efficiency

- How does a high-precision laboratory oven ensure the performance of large-scale halide perovskite catalyst plates?

- How does a gas path control system protect the materials? Ensure High Yields in Battery Smelting

- Why are rotary evaporators or industrial ovens recommended for handling Boron Carbide mixed slurries containing solvents?

- How does the Flash Heating (FH) process impact the growth of REBCO films? Master Rapid Thermal Ramp Requirements

- What is the primary purpose of 24-hour wet milling for SSBSN ceramics? Achieve Atomic-Scale Homogeneity

- Why is a high-precision furnace critical for refractory castables? Ensure Structural Integrity & Mineral Stability

- What function does a laboratory drying oven serve in the processing of PZT precursor powders? Optimize Ceramic Quality