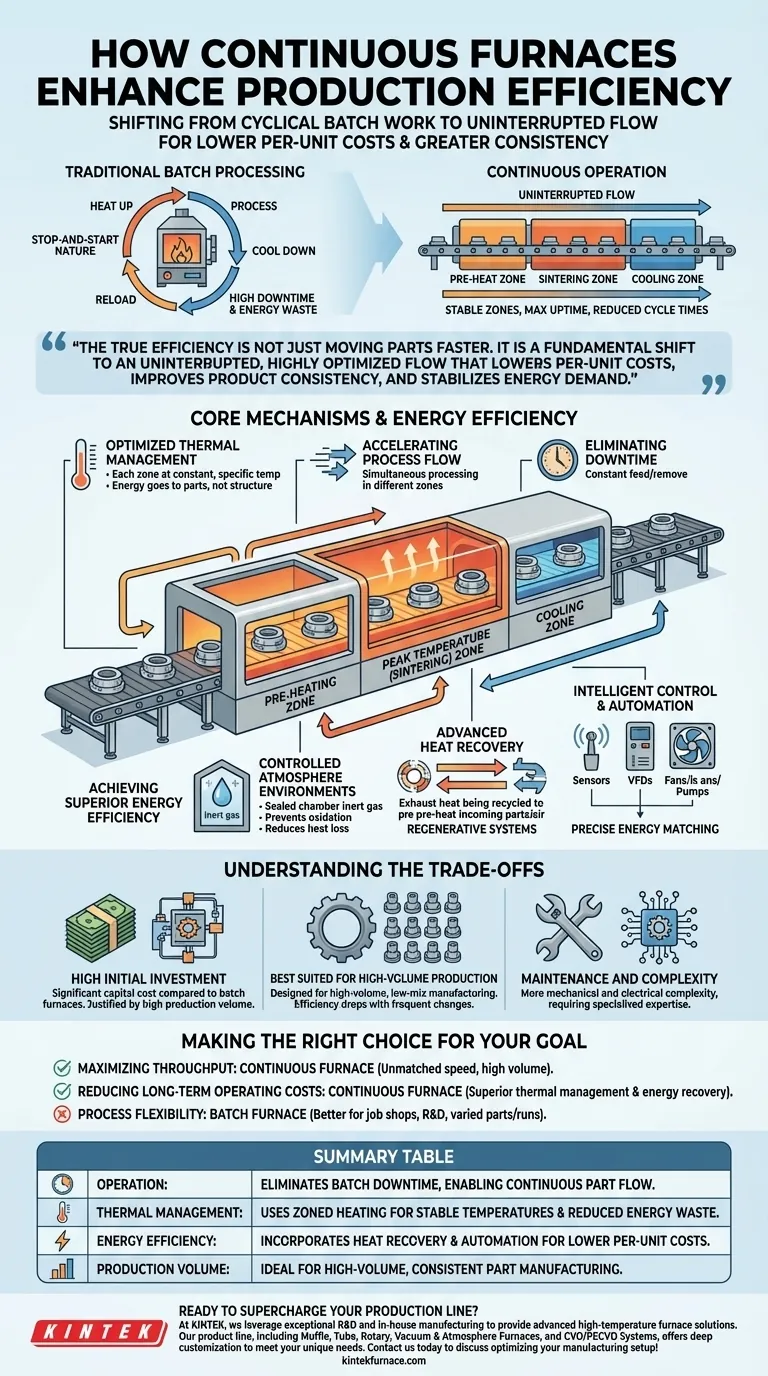

At their core, continuous furnaces enhance production efficiency by eliminating the stop-and-start nature of traditional batch processing. Instead of heating and cooling the entire furnace for each load, they maintain stable temperature zones through which parts move continuously, drastically reducing cycle times and energy waste while maximizing operational uptime.

The true efficiency of a continuous furnace is not just about moving parts faster. It is a fundamental shift from cyclical batch work to an uninterrupted, highly optimized flow that lowers per-unit costs, improves product consistency, and stabilizes energy demand.

The Core Mechanisms of Continuous Operation

The primary advantage of a continuous furnace comes from its design, which is fundamentally different from a batch furnace that must complete a full thermal cycle for every load.

Eliminating Downtime Between Batches

In a traditional batch furnace, significant time and energy are lost waiting for the chamber to cool, be reloaded, and then heated back to temperature.

A continuous furnace operates without interruption. Parts are constantly fed into one end and removed from the other, eliminating the non-productive time associated with loading and reheating an entire chamber.

Optimized Thermal Management

Most continuous furnaces utilize a multiple-chamber or zoned design. Each zone is held at a specific, constant temperature required for a particular stage of the heat-treating process (e.g., pre-heating, sintering, cooling).

This means the available energy is consumed almost exclusively by the parts themselves, not by reheating the furnace structure. This leads to a more consistent and predictable electrical load, avoiding the costly demand spikes common with large batch furnaces.

Accelerating Process Flow

By allowing different processes to occur simultaneously in different zones, a continuous furnace dramatically increases throughput. A part can be pre-heating in the first zone while another is sintering at peak temperature in the next.

This simultaneous processing minimizes transfer-related errors and bottlenecks that occur when moving parts between separate single-purpose furnaces.

Achieving Superior Energy Efficiency

Beyond simply running nonstop, continuous furnaces incorporate specific technologies designed to minimize energy consumption per part produced.

Controlled Atmosphere Environments

Many designs create a controlled environment using inert or reactive gases. This atmosphere prevents oxidation of the parts, which improves final product quality, but it also serves to reduce ambient heat loss from the chamber.

Advanced Heat Recovery

Modern continuous furnaces often include regenerative systems that capture and recycle heat from the hot exhaust gases. This recovered energy is then used to pre-heat incoming parts or combustion air, significantly reducing the amount of new energy required.

Intelligent Control and Automation

Advanced control systems and sensors constantly monitor and adjust heating parameters to maintain optimal conditions.

Furthermore, components like pumps and fans are often equipped with variable frequency drives (VFDs). These drives precisely match the motor's speed—and thus its energy consumption—to the exact demand of the system, eliminating wasted power.

Understanding the Trade-offs

While highly efficient, a continuous furnace is a specialized tool. Its advantages are only realized under the right conditions.

High Initial Investment

Continuous furnaces are complex, integrated systems that represent a significant capital investment compared to simpler batch furnaces. The upfront cost is substantial and must be justified by production volume.

Best Suited for High-Volume Production

The greatest strength of a continuous furnace is also its primary constraint. It is designed for the high-volume, low-mix manufacturing of similar parts.

Its efficiency diminishes rapidly if you need to frequently change temperature profiles or process parameters for small, varied batches. The setup and stabilization time can negate any potential throughput gains.

Maintenance and Complexity

The conveyor systems, multiple control zones, and automated loaders that enable continuous operation also add layers of mechanical and electrical complexity. Maintenance can be more involved and require more specialized expertise than for a simple box furnace.

Making the Right Choice for Your Goal

Selecting the right furnace technology requires a clear understanding of your primary production objective.

- If your primary focus is maximizing throughput: A continuous furnace is the definitive choice for its unmatched speed and ability to produce a high volume of consistent parts.

- If your primary focus is reducing long-term operating costs: The superior thermal management and energy recovery systems of a continuous furnace offer significant savings on a per-unit basis in a high-volume setting.

- If your primary focus is process flexibility: A batch furnace is often a better choice for job shops or R&D environments that handle small runs of highly varied parts with different processing requirements.

Ultimately, aligning your furnace technology with your specific production volume and product mix is the key to unlocking true manufacturing efficiency.

Summary Table:

| Aspect | Benefit |

|---|---|

| Operation | Eliminates batch downtime, enabling continuous part flow |

| Thermal Management | Uses zoned heating for stable temperatures and reduced energy waste |

| Energy Efficiency | Incorporates heat recovery and automation for lower per-unit costs |

| Production Volume | Ideal for high-volume, consistent part manufacturing |

| Trade-offs | High initial investment and suited for low-mix processes |

Ready to supercharge your production line? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Whether you're aiming to maximize throughput or reduce operating costs, our continuous furnaces can deliver unmatched efficiency for your high-volume processes. Contact us today to discuss how we can optimize your manufacturing setup!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries