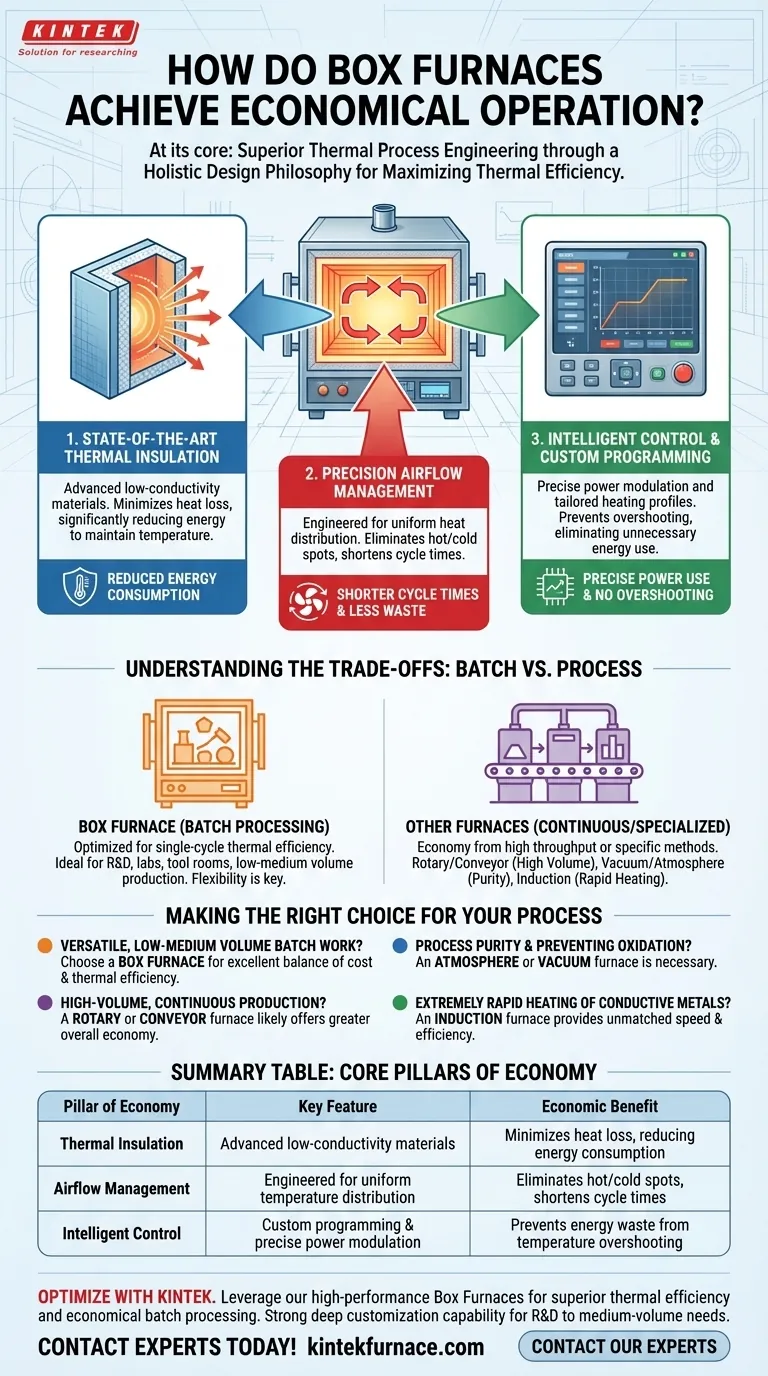

At its core, economical operation in a Box Furnace is achieved through superior thermal process engineering. This involves a focused strategy to minimize energy waste by combining three key elements: state-of-the-art insulation materials to contain heat, effective airflow management for uniform heating, and intelligent custom programming to optimize energy use during a cycle.

The central principle behind a Box Furnace's economy is not a single feature, but a holistic design philosophy focused on maximizing thermal efficiency. While other furnaces gain efficiency from continuous operation or specialized heating methods, the Box Furnace excels by perfecting the fundamentals of retaining and distributing heat within a self-contained batch process.

The Core Pillars of Box Furnace Economy

True operational economy is a direct result of minimizing wasted energy. A Box Furnace is engineered from the ground up to combat the primary sources of inefficiency in heat treatment.

State-of-the-Art Thermal Insulation

Heat loss is the single greatest enemy of furnace efficiency. Every unit of thermal energy that escapes the chamber must be replaced by the heating elements, consuming more power.

Modern Box Furnaces utilize advanced insulation materials with extremely low thermal conductivity. This ensures the vast majority of heat generated is kept inside the chamber and directed at the workload, significantly reducing the energy required to reach and maintain temperature.

Precision Airflow Management

Uniform temperature throughout the chamber is critical. Inefficient airflow creates hot and cold spots, forcing longer cycle times or higher temperature setpoints to ensure the entire load is properly treated.

By engineering effective airflow management, a Box Furnace ensures that heat is distributed evenly and efficiently. This guarantees that all parts of the workload reach the target temperature simultaneously, minimizing cycle time and preventing the energy waste associated with overheating certain areas to compensate for others.

Intelligent Control and Custom Programming

Crude on/off heating cycles are notoriously inefficient, often leading to temperature overshooting that wastes significant energy.

Box Furnaces leverage sophisticated control systems and custom programming. These systems precisely modulate power to the heating elements, preventing overshooting and allowing users to create specific heating profiles (heat-up, soak, cool-down) tailored perfectly to the material being processed. This eliminates unnecessary energy expenditure at every stage of the cycle.

Understanding the Trade-offs: Batch vs. Process

The economic model of a Box Furnace is tied to its function as a batch-processing unit. Understanding this context is key to comparing it with other technologies.

The Efficiency of Batch Processing

A Box Furnace is designed to perfect the thermal efficiency within a single, defined cycle. Its strength lies in its versatility for handling different part sizes, geometries, and process requirements from one batch to the next.

This makes it an extremely economical choice for labs, research and development, tool rooms, and low-to-medium volume production where flexibility is as important as energy cost.

When Other Furnaces Are More Economical

For high-volume, continuous production of a uniform product, a rotary or conveyor furnace may offer greater overall economy. Their efficiency comes not from thermal perfection in a static chamber, but from high throughput and uninterrupted operation.

Similarly, specialized furnaces gain efficiency in other ways. Vacuum and atmosphere furnaces create controlled environments that prevent heat loss and material waste from oxidation. Induction furnaces achieve incredible efficiency by transferring energy directly into the metal, bypassing the need to heat a large chamber.

Making the Right Choice for Your Process

Choosing the most economical furnace requires matching the technology's core strengths to your operational goals.

- If your primary focus is versatile, low-to-medium volume batch work: A Box Furnace offers an excellent balance of upfront cost and operational economy through its mastery of fundamental thermal efficiency.

- If your primary focus is high-volume, continuous production: A rotary or conveyor-style furnace will likely provide greater overall economy due to its high throughput and minimal downtime between loads.

- If your primary focus is process purity and preventing material oxidation: An atmosphere or vacuum furnace is necessary, with its economic benefits stemming from both energy conservation and superior product quality.

- If your primary focus is extremely rapid heating of conductive metals: An induction furnace provides unmatched speed and energy efficiency by heating the material directly, minimizing thermal waste.

Ultimately, understanding how each furnace technology achieves its efficiency empowers you to select the right tool for your specific application.

Summary Table:

| Pillar of Economy | Key Feature | Economic Benefit |

|---|---|---|

| Thermal Insulation | Advanced low-conductivity materials | Minimizes heat loss, reducing energy consumption |

| Airflow Management | Engineered for uniform temperature distribution | Eliminates hot/cold spots, shortens cycle times |

| Intelligent Control | Custom programming & precise power modulation | Prevents energy waste from temperature overshooting |

Optimize your lab's energy efficiency and operational costs with a high-performance Box Furnace from KINTEK.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our Box Furnaces are engineered for superior thermal efficiency, ensuring economical operation for your batch processing needs. Whether for R&D, tool rooms, or medium-volume production, our strong deep customization capability allows us to precisely meet your unique experimental requirements.

Ready to enhance your heat treatment process with an economical and reliable solution? Contact our experts today to discuss how a KINTEK Box Furnace can benefit your specific application!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate

- What is the significance of temperature control precision in high-temperature furnaces for carbon-doped titanium dioxide?

- How is a muffle furnace utilized for AlN crystal post-processing? Optimize Surface Purity via Staged Oxidation