In a modern dental furnace, software errors can cause unpredictable behavior, leading to incorrect firing cycles, unresponsive controls, and the loss of custom settings. The most effective preventive measures are maintaining a strict software update schedule, regularly backing up all custom programs, and establishing a clear protocol for contacting manufacturer support when an issue arises.

The integration of sophisticated software has transformed dental furnaces into powerful, precise tools. However, this reliance introduces a new category of risk that must be managed proactively through disciplined maintenance and data management, not just reactive troubleshooting.

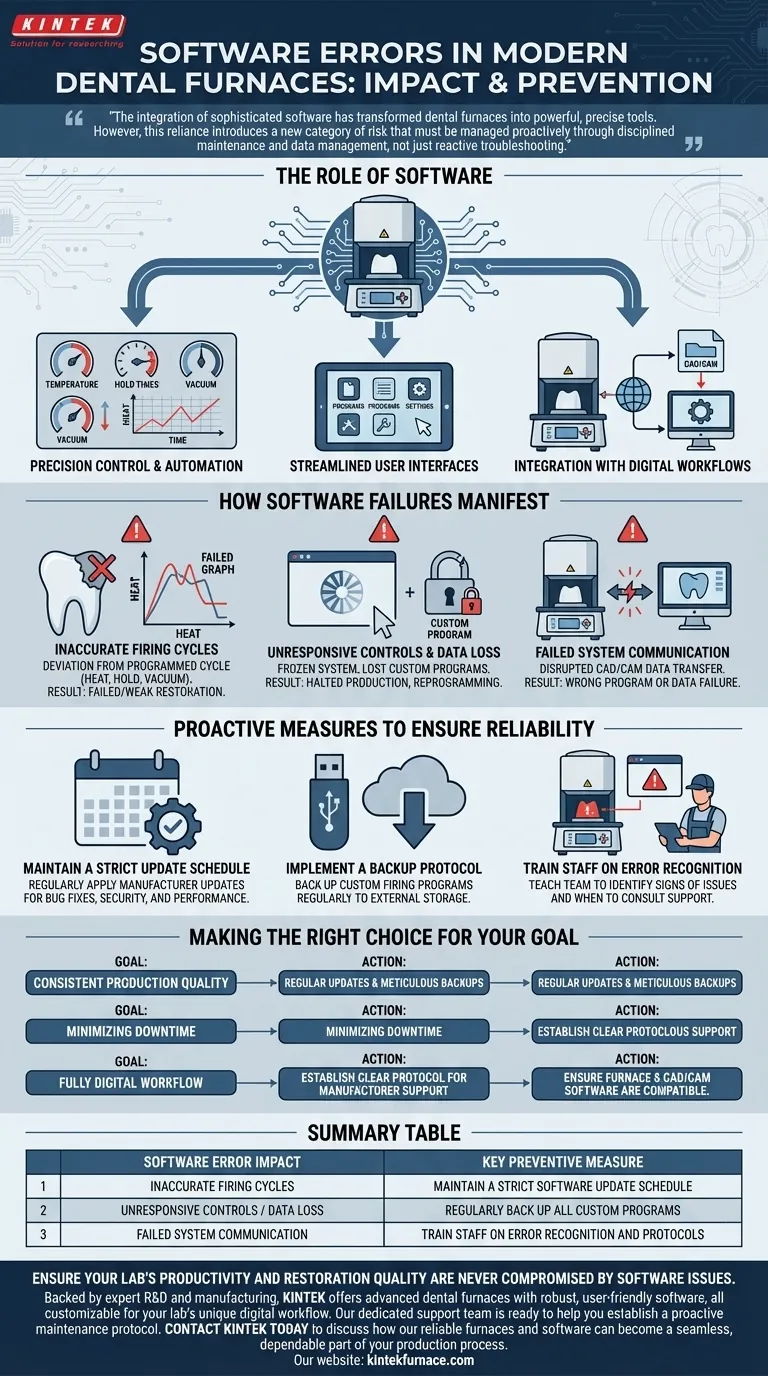

The Role of Software in the Modern Dental Lab

The operational heart of a contemporary dental furnace is its software. This is no longer a simple timer but a complex control system that dictates the success of every restoration.

Precision Control and Automation

Software manages the most critical variables in the firing process, including precise temperature ramp rates, hold times, and vacuum levels. This automation allows for highly repeatable results that are difficult to achieve manually.

Streamlined User Interfaces

Modern furnaces utilize user-friendly interfaces with features like touchscreen displays and programmable memory. This technology simplifies operation, reduces the potential for user error, and shortens the training time for new technicians.

Integration with Digital Workflows

Connectivity through USB or network ports is crucial for labs using a digital workflow. Software enables the furnace to integrate directly with CAD/CAM systems, creating a seamless process from design to final fabrication.

How Software Failures Manifest

A software glitch is not just a minor inconvenience; it can directly compromise the quality of the final product and disrupt your entire lab's schedule.

Inaccurate Firing Cycles

The most damaging error is a deviation from the programmed firing cycle. A software bug could cause the furnace to heat too quickly, hold at the wrong temperature, or fail to apply vacuum correctly, resulting in a failed or structurally weak restoration.

Unresponsive Controls and Data Loss

Software can freeze or become unresponsive, halting production entirely. A more insidious issue is data corruption, where custom-programmed firing schedules for specific materials are lost, forcing technicians to reprogram them from scratch.

Failed System Communication

In an integrated lab, a software error can disrupt communication between the furnace and the CAD/CAM system. This can lead to the wrong program being run or a complete failure to transfer necessary data for a job.

Proactive Measures to Ensure Reliability

Treating your furnace's software with the same care as its physical components is essential for preventing costly failures. A proactive approach is always superior to a reactive one.

Maintain a Strict Update Schedule

Regularly updating the furnace's software is the single most important preventive measure. Manufacturers release updates to fix known bugs, patch security vulnerabilities, and improve performance. Ignoring them leaves your equipment exposed to predictable failure points.

Implement a Backup Protocol

Custom firing programs are valuable intellectual property for a lab. Back up these settings regularly to a USB drive or network location. This ensures that if the furnace's memory is wiped by an error or hardware failure, you can restore your operations in minutes, not days.

Train Staff on Error Recognition

Your team should be trained to recognize the signs of a software issue, from unusual screen behavior to error messages. Knowing when to stop a cycle and consult support can prevent the loss of valuable materials and time.

Making the Right Choice for Your Goal

Adopting a clear protocol for software management turns your advanced furnace from a potential liability into a consistent and reliable production asset.

- If your primary focus is consistent production quality: Make regular software updates and meticulous backups of all custom firing programs a non-negotiable part of your maintenance routine.

- If your primary focus is minimizing downtime: Establish a clear protocol for when to contact manufacturer support immediately versus attempting in-house troubleshooting for any software anomaly.

- If your primary focus is a fully digital workflow: Ensure both the furnace and your CAD/CAM software are always on compatible, manufacturer-approved versions to prevent data communication errors.

Ultimately, proactive management of your equipment's software is the key to leveraging its full potential while safeguarding your lab's productivity.

Summary Table:

| Software Error Impact | Key Preventive Measure |

|---|---|

| Inaccurate Firing Cycles | Maintain a strict software update schedule |

| Unresponsive Controls / Data Loss | Regularly back up all custom programs |

| Failed System Communication | Train staff on error recognition and protocols |

Ensure your lab's productivity and restoration quality are never compromised by software issues.

Backed by expert R&D and manufacturing, KINTEK offers advanced dental furnaces with robust, user-friendly software, all customizable for your lab's unique digital workflow. Our dedicated support team is ready to help you establish a proactive maintenance protocol.

Contact KINTEL today to discuss how our reliable furnaces and software can become a seamless, dependable part of your production process.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique