In short, CAD/CAM technology is the primary method used to transform a solid block of zirconia into a precise, high-strength dental restoration. The process involves digitally designing the restoration (CAD) and then using an automated milling machine to carve it (CAM) before it undergoes a final hardening process called sintering.

The core function of CAD/CAM in zirconia dentistry is to replace traditional, manual lab techniques with a highly accurate and repeatable digital workflow. This is what makes it possible to work with an exceptionally strong material like zirconia, which is too hard to be effectively shaped by hand.

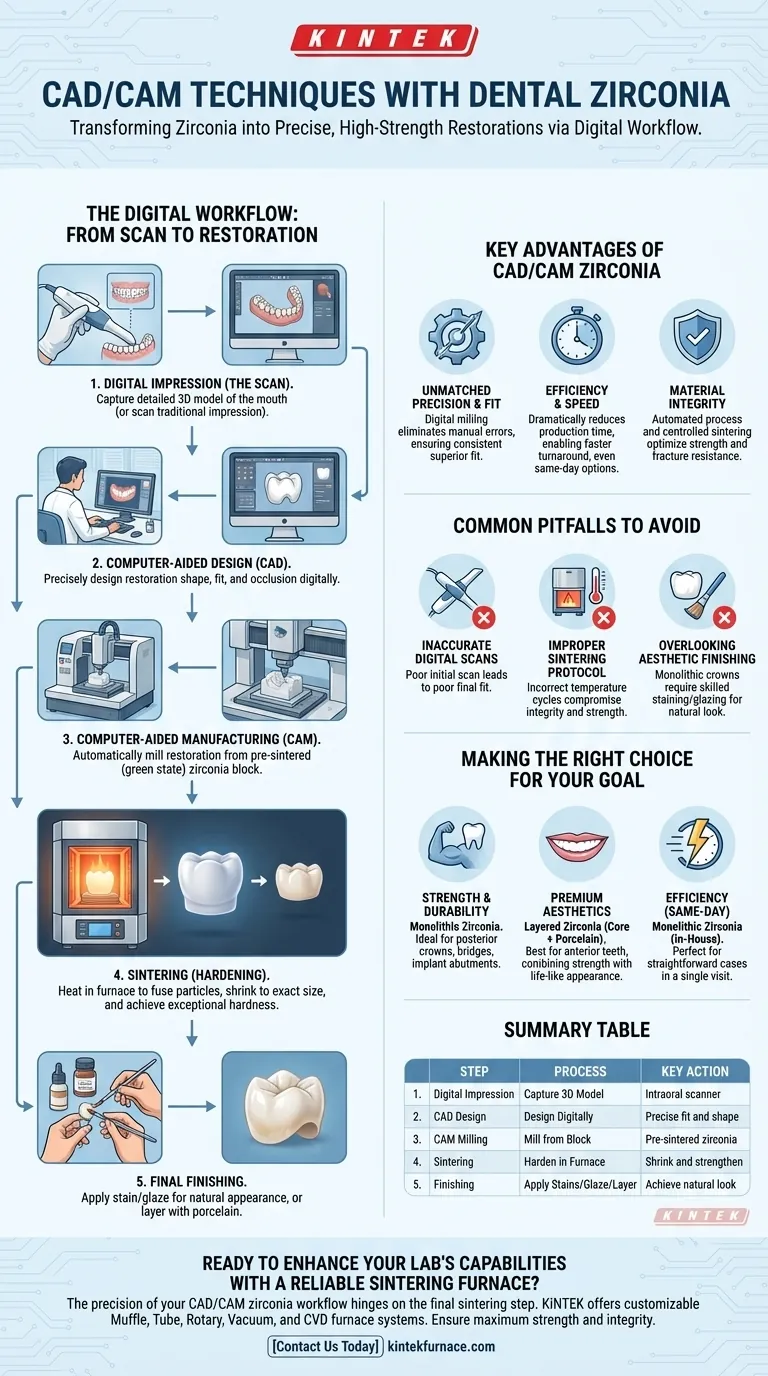

The Digital Workflow: From Scan to Restoration

The entire process is a seamless integration of digital capture, design, and automated manufacturing. Each step builds upon the last to create a restoration with a precise fit and function.

Step 1: Digital Impression (The Scan)

The process begins by creating a detailed 3D model of the patient's mouth. This is typically done with an intraoral scanner that captures the tooth preparations, surrounding teeth, and bite registration directly. Alternatively, a traditional physical impression can be taken and then scanned in the dental lab.

Step 2: Computer-Aided Design (CAD)

This digital model is imported into specialized CAD software. A dental technician then designs the final restoration—be it a crown, bridge, or implant abutment—on the computer. They can precisely control the shape, contact points, and occlusion (the bite) to ensure a perfect fit before any physical material is touched.

Step 3: Computer-Aided Manufacturing (CAM)

Once the design is finalized, the digital file is sent to a milling machine. This machine automatically and precisely carves the restoration out of a block of pre-sintered zirconia, often called its "green state." In this chalk-like state, the zirconia is soft enough to be milled accurately.

Step 4: Sintering (Hardening in the Furnace)

The milled zirconia restoration is still soft and oversized to account for shrinkage. It is then placed in a specialized high-temperature furnace. This sintering process heats the zirconia, causing the particles to fuse together, which shrinks the restoration to its exact design dimensions and gives it its final, exceptional hardness and strength.

Step 5: Final Finishing

After sintering, the restoration is rock-hard. To achieve a natural appearance, technicians use various finishing techniques. This can be a simple stain and glaze to match the color and luster of adjacent teeth or more complex layering with porcelain for premium aesthetic results.

Understanding the Key Advantages

Using CAD/CAM for zirconia isn't just an alternative; it is the enabling technology that makes modern zirconia restorations possible.

Unmatched Precision and Fit

Zirconia is an extremely strong material, but it is also very difficult to work with using traditional methods. The digital precision of CAM milling eliminates the human errors and material distortions inherent in older casting techniques, resulting in a consistently superior fit.

Efficiency and Speed

The digital workflow dramatically reduces the time required to produce a restoration. What once took multiple appointments and days of manual lab work can now often be condensed, with some systems even allowing for same-day crowns.

Material Integrity

The automated nature of CAM milling and the controlled environment of the sintering furnace ensure the material's properties are optimized. This leads to restorations that are not only well-fitting but also incredibly durable and resistant to fracture.

Common Pitfalls to Avoid

While the technology is advanced, the final quality still depends on proper execution at critical stages.

Inaccurate Digital Scans

The entire process is based on the initial scan. A poor or incomplete scan will lead to a poorly fitting restoration, regardless of how well the subsequent steps are performed. "Garbage in, garbage out" is the rule.

Improper Sintering Protocol

Sintering is the most critical step for achieving zirconia's final strength. Using the wrong temperature cycle or heating/cooling the furnace too quickly can introduce internal stresses and micro-fractures, compromising the restoration's integrity and leading to premature failure.

Overlooking Aesthetic Finishing

While CAD/CAM creates a perfectly shaped restoration, a monolithic (single-shade) zirconia crown can appear opaque and unnatural without proper finishing. Skilled application of stains and glazes is essential to blend the restoration with the patient's natural dentition.

Making the Right Choice for Your Goal

The application of CAD/CAM zirconia depends heavily on the clinical objective.

- If your primary focus is strength and durability: A monolithic zirconia restoration, milled and sintered correctly, is the ideal choice for posterior crowns, multi-unit bridges, and implant abutments where chewing forces are highest.

- If your primary focus is premium aesthetics: For anterior teeth, consider a milled zirconia core that is then layered with porcelain. This combines the strength of the zirconia substructure with the life-like appearance of hand-layered ceramics.

- If your primary focus is efficiency: A monolithic zirconia crown designed and milled in-house can provide a strong, functional restoration in a single patient visit, making it perfect for straightforward cases.

Mastering this digital workflow is essential for unlocking the full potential of modern high-performance dental ceramics.

Summary Table:

| Step | Process | Key Action |

|---|---|---|

| 1 | Digital Impression | Capture a 3D model of the mouth with an intraoral scanner. |

| 2 | CAD Design | Design the restoration digitally for a precise fit. |

| 3 | CAM Milling | Mill the restoration from a pre-sintered zirconia block. |

| 4 | Sintering | Harden and shrink the restoration in a high-temperature furnace. |

| 5 | Finishing | Apply stains, glazes, or porcelain for a natural appearance. |

Ready to enhance your lab's capabilities with a reliable sintering furnace?

The precision of your CAD/CAM zirconia workflow hinges on the final sintering step. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD furnace systems, all customizable for your lab's unique needs. Ensure your restorations achieve maximum strength and integrity with a furnace built for accuracy and durability.

Contact us today to find the perfect high-temperature furnace for your dental lab!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision