Yes, but it is a critical distinction. While the "box" shape describes the form factor, not all box-type furnaces can control their atmosphere. True atmosphere control is a feature of a specific sub-category—the atmosphere furnace—which is fundamentally different in design and purpose from a standard box resistance furnace that operates only in air.

Choosing a furnace is not just about hitting a target temperature. The central decision rests on whether your material can tolerate exposure to air during heating. A standard box furnace is an oven; an atmosphere furnace is a sealed, controlled environment designed to prevent oxidation and enable specific material reactions.

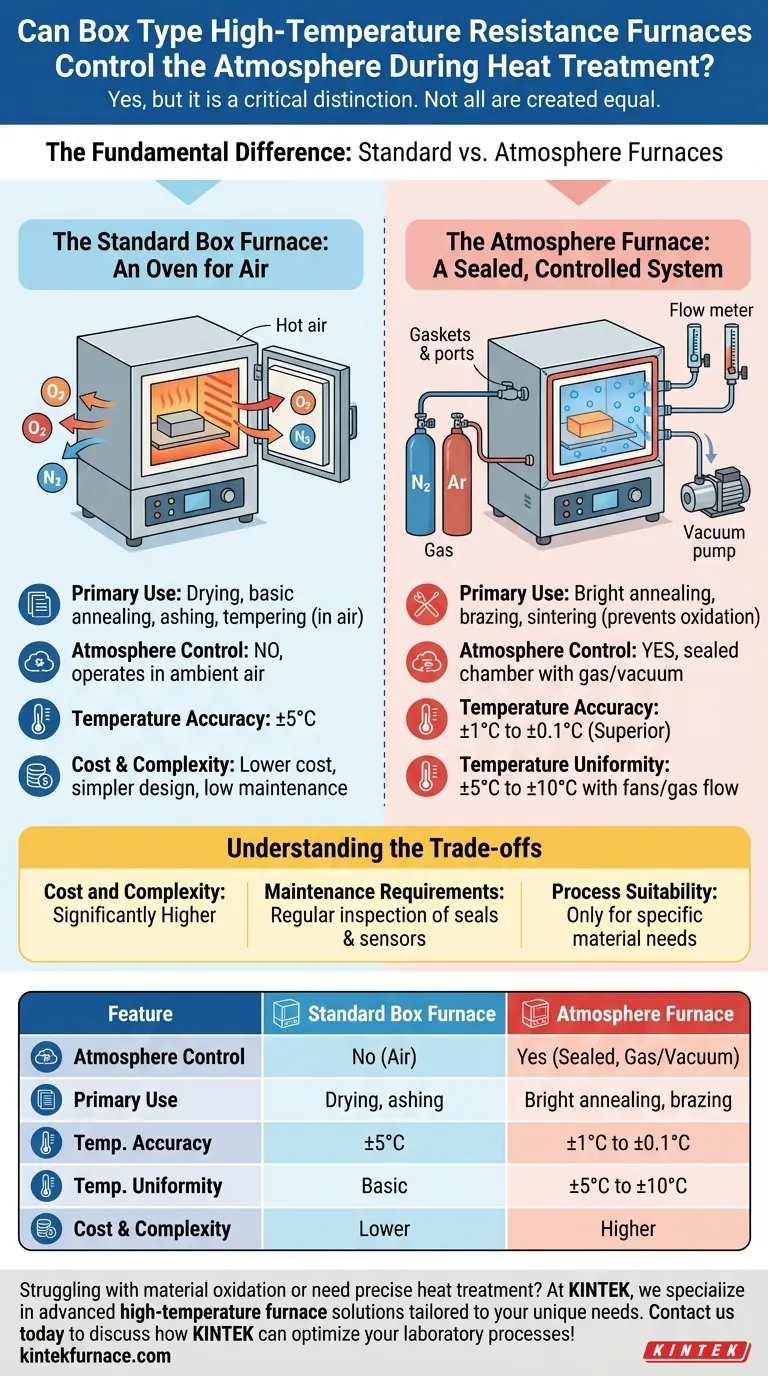

The Fundamental Difference: Standard vs. Atmosphere Furnaces

Understanding the distinction between these two types of furnaces is the most important step in selecting the right equipment for your heat treatment process. They serve entirely different purposes.

The Standard Box Furnace: An Oven for Air

A standard box-type resistance furnace is designed for simplicity and efficiency in an ambient air environment. Its primary job is to heat a workpiece to a specific temperature.

These furnaces are ideal for processes like drying, basic annealing, ashing, or tempering where interaction with oxygen and nitrogen in the air is either acceptable or desired. Their temperature control accuracy is generally within ±5°C, which is suitable for many common applications.

The Atmosphere Furnace: A Sealed, Controlled System

An atmosphere furnace, which often comes in a box-type configuration, is a specialized piece of equipment. Its defining feature is a perfectly sealed chamber with inlets and outlets for managing its internal environment.

This design allows you to remove the air (via a vacuum pump) and introduce a specific gas. Its purpose is to perform heat treatment under a controlled atmosphere to prevent unwanted chemical reactions like oxidation and decarburization, ensuring the material's surface and integrity are preserved.

Key Characteristics of an Atmosphere Furnace

Atmosphere furnaces provide a level of process control that is impossible to achieve with a standard furnace. Their capabilities are a direct result of their specialized design.

Precise Atmosphere Control

The core function is to create a non-reactive environment. This is typically achieved by introducing a protective or inert gas, such as nitrogen (N2) or argon (Ar), after first purging the chamber of air. This is essential for bright annealing, brazing, and sintering of sensitive metals.

Superior Temperature Accuracy

Because the processes requiring atmosphere control are often more sensitive, these furnaces are built with higher-precision temperature control systems. They can typically achieve an accuracy of ±1°C to ±2°C, with advanced models reaching as low as ±0.1°C for demanding applications like semiconductor processing.

Enhanced Temperature Uniformity

In addition to accuracy (hitting a setpoint), uniformity (even temperature throughout the chamber) is critical. Atmosphere furnaces often use circulating fans or leverage the flow of the process gas to distribute heat more evenly, typically maintaining uniformity within ±5°C to ±10°C and ensuring the entire workpiece receives the same thermal treatment.

Understanding the Trade-offs

While powerful, an atmosphere furnace is not always the right choice. Its specialized nature comes with clear trade-offs in cost and complexity.

Cost and Complexity

Atmosphere furnaces are significantly more expensive than standard box furnaces. The sealed chamber, gas delivery systems, vacuum pumps, and advanced sensors all add to the initial investment and operational complexity.

Maintenance Requirements

The integrity of the system depends on its seal. Gaskets, valves, and gas flow sensors require regular inspection and maintenance to prevent leaks and ensure the purity of the internal atmosphere. A compromised seal defeats the entire purpose of the furnace.

Process Suitability

Using an atmosphere furnace for a simple process that can be done in air is inefficient. It introduces unnecessary cost, setup time, and potential points of failure. The primary driver must be a genuine material science need to protect the workpiece from air.

Making the Right Choice for Your Process

Selecting the correct furnace requires a clear understanding of your material and your desired outcome. Your decision should be based on the specific demands of your application.

- If your primary focus is basic heating, drying, or ashing in air: A standard box furnace is the most cost-effective and straightforward solution.

- If your primary focus is preventing oxidation, decarburization, or achieving a bright finish: A box-type atmosphere furnace is essential for protecting your material.

- If your primary focus is high-precision material processing like semiconductor annealing or advanced ceramics: You need a high-precision atmosphere furnace with superior temperature accuracy and documented uniformity.

Ultimately, your choice is defined by the chemistry of your process; match the furnace's capability to your material's specific needs.

Summary Table:

| Feature | Standard Box Furnace | Atmosphere Furnace |

|---|---|---|

| Atmosphere Control | No, operates in air | Yes, sealed with gas/vacuum |

| Primary Use | Drying, ashing, basic annealing | Bright annealing, brazing, sintering |

| Temperature Accuracy | ±5°C | ±1°C to ±0.1°C |

| Temperature Uniformity | Basic | ±5°C to ±10°C with fans |

| Cost and Complexity | Lower | Higher with maintenance |

Struggling with material oxidation or need precise heat treatment? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization capabilities. Whether you're in research, semiconductor processing, or advanced ceramics, our furnaces ensure superior temperature control and atmosphere management to protect your materials and enhance results. Contact us today to discuss how KINTEK can optimize your laboratory processes!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity