You’ve done everything right. The material is pure, the process is meticulously documented, and your furnace is rated to 1700°C. You set the controller to 1650°C for a critical sintering process. Yet, the samples emerging from the chamber are a maddening mix of inconsistency—some perfect, others cracked, warped, or failing to meet spec.

Days, even weeks, are lost chasing phantom variables. You question the material supplier, you recalibrate your measurement tools, you tweak the process parameters. But the results remain stubbornly, expensively unpredictable. If this sounds familiar, you're not alone. And the root of the problem is hiding in plain sight.

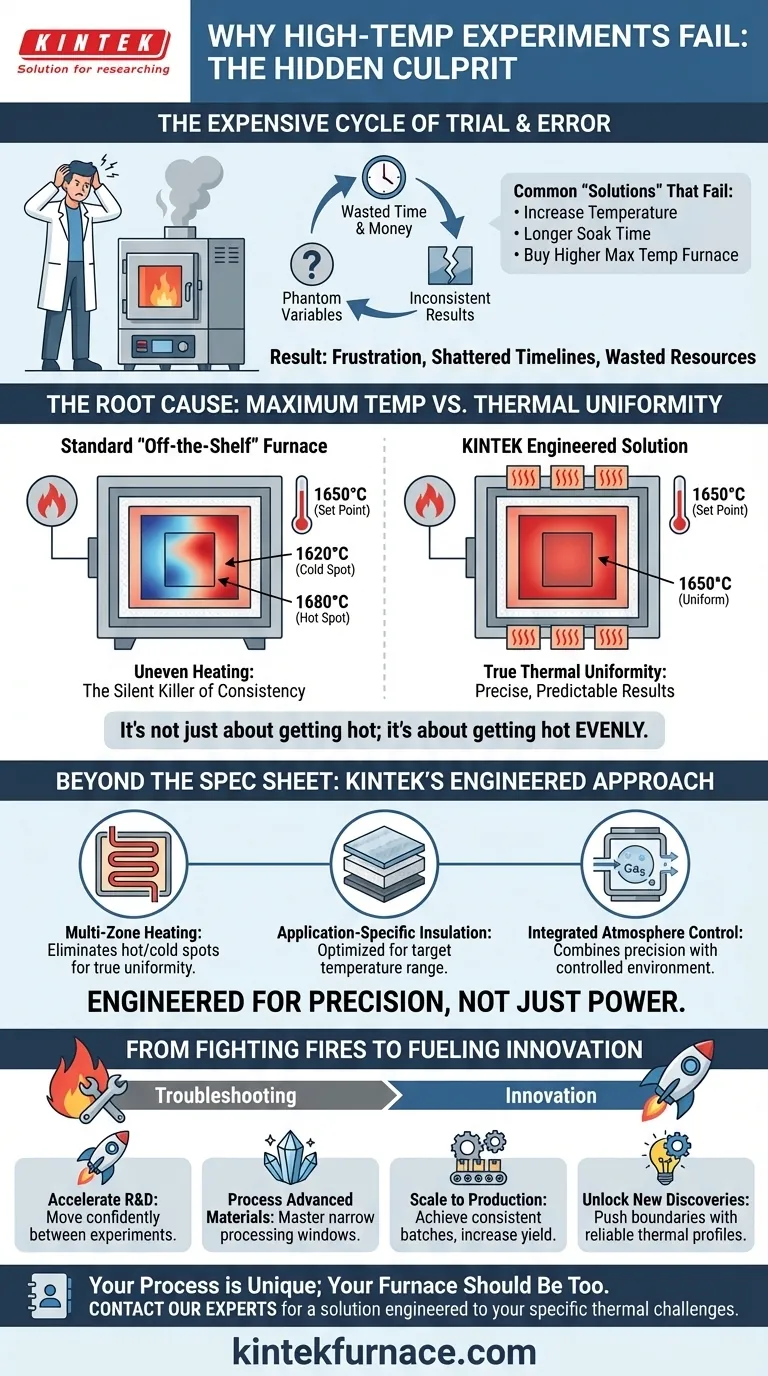

The Expensive Cycle of Trial and Error

This scenario plays out in advanced R&D labs and high-stakes manufacturing facilities every day. The initial assumption is almost always that a furnace with a high enough maximum temperature rating is a guarantee of performance. When results go wrong, the troubleshooting playbook is predictable:

- "Let's just increase the temperature." You push the furnace closer to its limit, hoping more heat will solve the problem, often making it worse.

- "We'll try a longer soak time." This wastes energy and valuable machine time, without addressing the underlying issue.

- "We need a furnace with an even higher max temp." This is the most common and costly mistake—investing in more power without understanding the real problem.

This cycle isn't just frustrating; it has severe business consequences. Project timelines are shattered, R&D budgets are consumed by wasted materials and energy, and the inability to scale a process reliably can halt the launch of a new product entirely. You're left with a process that is more art than science, completely dependent on luck.

The Root Cause: Maximum Temperature vs. Thermal Uniformity

Here is the critical turning point: The problem is rarely the maximum temperature your furnace can reach. The true culprit is a lack of thermal uniformity.

Think of a standard kitchen oven. The dial may be set to 400°F, but you know from experience that the back corner runs hot and will burn cookies, while the front leaves them undercooked. Now, amplify this effect to the extreme temperatures used for advanced ceramics, alloys, or crystal growth.

A furnace's temperature controller might read a steady 1650°C from a single thermocouple, but inside the chamber, a hidden thermal battle is raging. One part of your sample could be sitting at 1680°C while another is at 1620°C. This temperature gradient, this uneven heating, is the silent killer of consistency.

This is precisely why the common "solutions" fail. Turning up the heat doesn't create uniformity; it just makes the hot spots hotter. A longer soak can't compensate for a fundamental design flaw that prevents even heat distribution. You're trying to fix a hardware problem with a software tweak, and it will never work reliably.

Beyond the Spec Sheet: A Furnace Engineered for Your Process

To achieve repeatable, predictable results, you don't just need a furnace that gets hot. You need a thermal instrument engineered for precision—a system designed to deliver the exact same temperature to every square millimeter of your sample, every single run.

This is where the concept of "off-the-shelf" breaks down. A generic furnace is built to hit a number on a spec sheet. A true process solution, however, is built around your specific thermal requirements. This is the principle behind KINTEK's approach. We recognize that achieving perfect uniformity at 1200°C is a completely different engineering challenge than at 1700°C, especially when a controlled atmosphere is required.

Our deep customization capability allows us to address the root cause directly:

- Multi-Zone Heating: Instead of one brute-force heating element, we can engineer multiple, independently controlled heating zones to eliminate hot and cold spots, ensuring true thermal uniformity across the entire chamber.

- Application-Specific Insulation: We select and design insulation packages that are optimized for your target temperature range, minimizing heat loss and improving stability.

- Integrated Atmosphere Control: For processes sensitive to oxidation, our Vacuum & Atmosphere Furnaces combine high-temperature precision with a perfectly controlled environment, ensuring the material's integrity is never compromised.

A KINTEK furnace isn’t just a product; it’s a solution born from a deep understanding of thermal dynamics. It's designed not just to reach a temperature, but to master it.

From Fighting Fires to Fueling Innovation

When your thermal process is truly stable and uniform, the entire dynamic of your work changes. The energy once spent on troubleshooting and re-running failed experiments is liberated. You can now:

- Accelerate R&D: Move confidently from one successful experiment to the next, knowing the results are reliable and the furnace is not a variable.

- Process Advanced Materials: Work with next-generation materials that have incredibly narrow processing windows, which would be impossible in a non-uniform furnace.

- Scale to Production: Transition a process from the lab to the production line with the assurance that results will be consistent, batch after batch, increasing yield and profitability.

- Unlock New Discoveries: Push the boundaries of what's possible, exploring new material compositions and thermal profiles, free from the constraints of unpredictable equipment.

You stop being a furnace operator and become a true materials scientist or process engineer again, focused on innovation instead of mitigation.

Your process is unique; your furnace should be too. Stop battling inconsistent results and start achieving predictable success. Our team of experts is ready to go beyond the spec sheet and discuss the specific thermal challenges in your project, engineering a solution that delivers the precision you need to move forward. Contact Our Experts to begin the conversation.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

Related Articles

- The Unseen Enemy: How Vacuum Furnaces Redefine Material Perfection

- More Than a Void: The Inherent Energy Efficiency of Vacuum Furnace Design

- Beyond the Heat: The Psychology of Perfect Vacuum Furnace Operation

- The Pursuit of Purity: Why a Vacuum Furnace Is a System for Creating Certainty

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything