You’ve run the distillation cycle for the fifth time. The material is a high-value alloy, the vacuum is holding steady, and the temperature profile seems perfect. Yet, the analysis comes back, and the purity levels are all over the place—nowhere near the 99.99% target. You spend days re-calibrating, tweaking ramp rates, and questioning every step of your process, but the results remain stubbornly inconsistent. If this scenario feels frustratingly familiar, you're not alone.

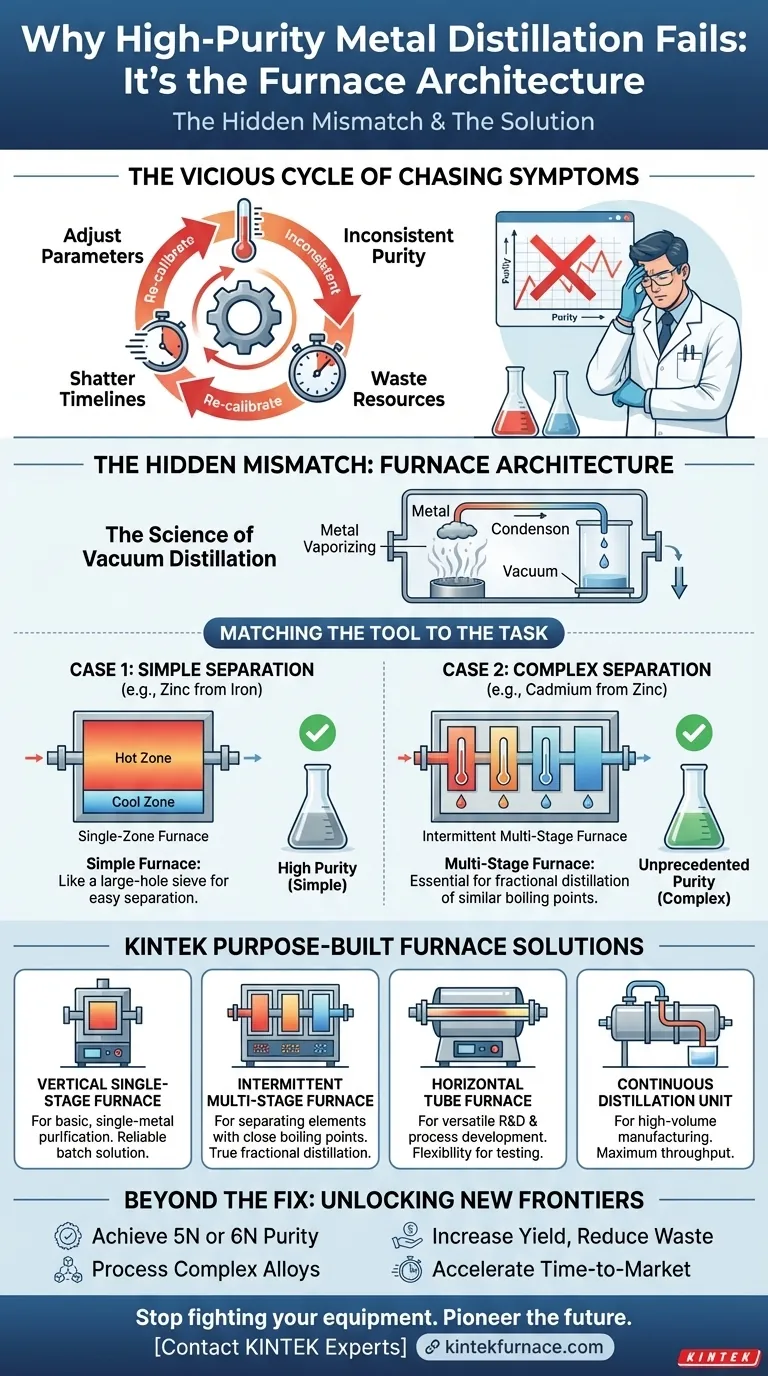

The Vicious Cycle of Chasing Symptoms

Many labs and production facilities get trapped in a costly loop when trying to purify metals via vacuum distillation. The typical response to poor results is to adjust the operational parameters:

- "Let's increase the holding time at peak temperature."

- "Maybe a deeper vacuum will pull out more impurities."

- "Let's try a slower cooling ramp."

While these adjustments might yield marginal improvements, they rarely solve the underlying problem. This leads to significant business consequences: project timelines are shattered, expensive raw materials are wasted, and R&D for next-generation products grinds to a halt. The team loses confidence, and the goal of producing materials with superior mechanical strength, ductility, or electrical properties remains just out of reach. The core issue isn't being addressed because everyone is looking in the wrong place.

The Hidden Mismatch: Why Furnace Architecture is the Real Culprit

The turning point comes when we stop asking, "Are my settings right?" and start asking, "Is my equipment right for the job?"

The fundamental reason most distillation efforts fail is a mismatch between the purification task and the furnace's physical design, or architecture. You can have the most advanced controller and the strongest vacuum pump, but if the furnace isn't built for your specific separation challenge, you will always be fighting a losing battle.

The science is straightforward. Vacuum distillation works by heating metals until they vaporize and then condensing that vapor elsewhere, leaving impurities behind. However, different purification tasks require fundamentally different physical setups.

Case 1: Simple vs. Complex Separation

Imagine you're separating a primary metal from an impurity with a very different boiling point (e.g., separating zinc from iron). A simple furnace with a single hot zone and a single cool condensation zone is perfectly adequate. This is like using a large-hole sieve to separate rocks from sand.

But what if you need to separate two metals with very similar boiling points (e.g., cadmium from zinc)? This is called fractional distillation. Tweaking the temperature in a single-zone furnace will never work. It’s like trying to separate fine sand from sugar with the same sieve—impossible. For this, you need a furnace with multiple, distinct condensation zones, each held at a precise, different temperature. This multi-stage architecture allows the different metal vapors to condense selectively, achieving a clean separation.

Case 2: Lab Scale vs. Production Scale

Similarly, a furnace designed for high-precision batch work in R&D is architecturally different from one built for high-throughput industrial production. A batch furnace, even a large one, cannot provide the efficiency of a continuous distillation unit specifically designed with feeding and discharge systems that operate without breaking the vacuum.

The common "fixes" fail because they are trying to change the software (the process parameters) when the problem is in the hardware (the furnace design).

Matching the Tool to the Task: The Principle of Purpose-Built Furnaces

To achieve consistent, high-purity results, you must move beyond thinking of a furnace as just a hot box. You need to see it as a purpose-built instrument where the architecture directly enables the desired metallurgical outcome.

This is precisely where a deep understanding of furnace engineering becomes critical. The solution isn't to buy a furnace with the highest temperature rating; it's to acquire a furnace architected for your specific goal:

- For basic, single-metal purification: A Vertical Single-Stage Furnace provides a reliable, cost-effective batch solution.

- For separating multiple elements with close boiling points: An Intermittent Multi-Stage Furnace with its distinct temperature zones is the only way to perform true fractional distillation effectively.

- For versatile R&D and process development: A Horizontal Tube Furnace offers the flexibility to test different conditions and atmospheres on a smaller scale.

- For high-volume manufacturing: A Continuous Distillation Unit is engineered for maximum throughput and uninterrupted operation.

This is where KINTEK's expertise transforms challenges into solutions. We don’t just sell products from a catalog; we leverage our deep R&D and in-house manufacturing capabilities to deliver furnace solutions that are precisely matched to your process. Our deep customization capability means we can design and build the exact multi-stage, continuous, or specialized atmosphere system that your unique purification challenge demands. We provide the right tool for the job, designed from the ground up based on the principles of your process.

Beyond the Fix: Unlocking New Material Frontiers

When your furnace is no longer an obstacle but an enabler, everything changes. The struggle to achieve baseline purity transforms into an exploration of what's possible.

With an architecture purpose-built for your needs, you can:

- Achieve unprecedented purity levels (e.g., 5N or 6N), unlocking novel material properties for cutting-edge applications in semiconductors, aerospace, and medical devices.

- Confidently process complex alloys that were previously too difficult to separate, opening up new avenues for research and product development.

- Dramatically increase yield and reduce waste, improving the economic viability of your entire operation.

- Accelerate your time-to-market by moving from successful R&D to scalable production with a clear and reliable technology pathway.

Stop letting a fundamental equipment mismatch dictate the limits of your success. By aligning your furnace architecture with your scientific goals, you move from fighting your equipment to pioneering the future of advanced materials.

Your material purification challenges are unique, and your furnace solution should be too. If you're ready to move past incremental tweaks and solve your distillation problems at their core, our team of experts is here to help design the precise thermal solution your project requires. Contact Our Experts to discuss how a purpose-built furnace can unlock the next stage of your innovation.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

Related Articles

- The Art of Isolation: Mastering Material Properties with Tube Furnaces

- Mastering the Void: How Tube Furnaces Engineer Predictable Outcomes

- Beyond Heat: The Physics of Control in a Tube Furnace

- Mastering the Void: How Tube Furnaces Forge the Atoms of Innovation

- Mastering the Micro-Environment: The Art and Science of the Laboratory Tube Furnace