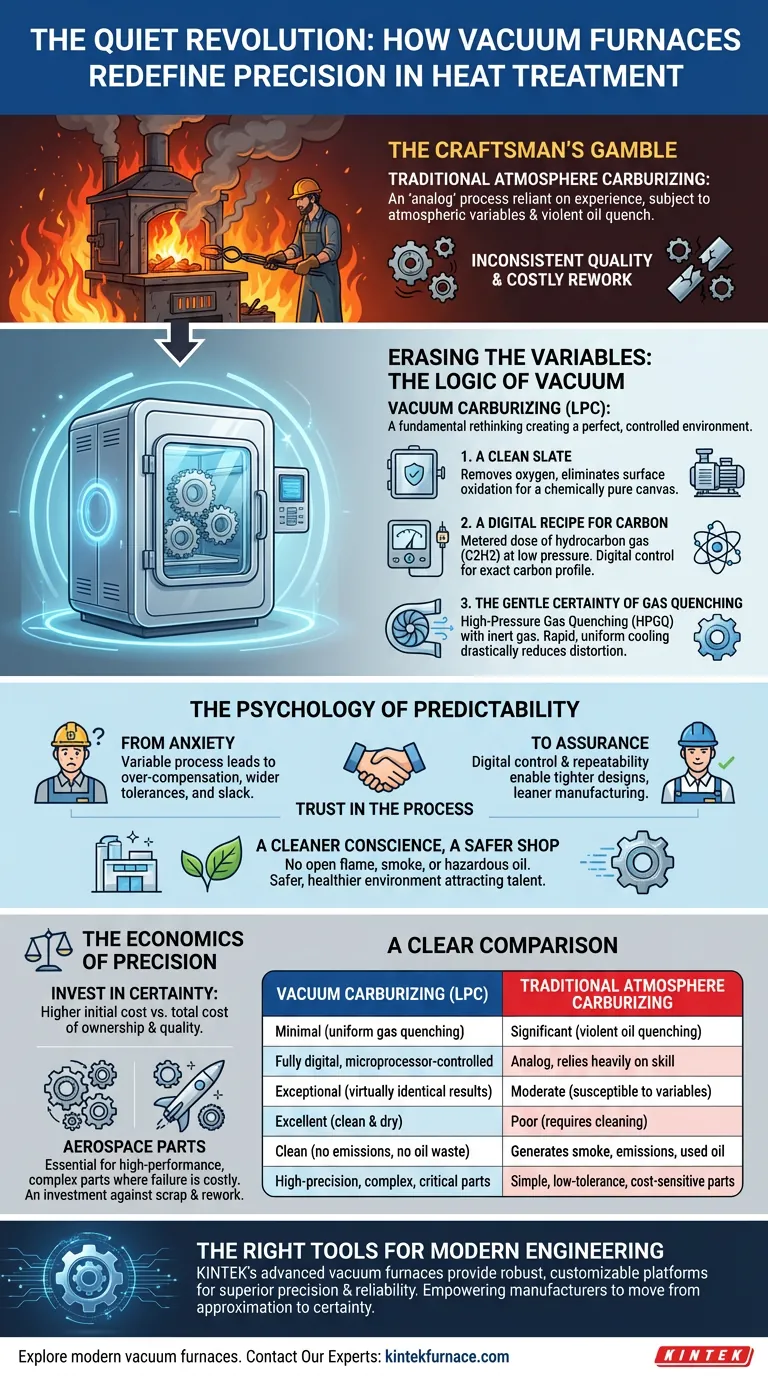

The Craftsman's Gamble

For decades, heat treatment felt more like a dark art than a precise science. An operator, relying on experience and intuition, would manage a fiery furnace, wrestling with atmospheric variables and the violent thermal shock of an oil quench.

The goal was simple: make a steel part hard on the outside but tough on the inside. Yet, the process was a gamble. Each batch was a negotiation with physics, and a slight variation in temperature, gas flow, or quenching speed could lead to warped parts, inconsistent quality, and costly rework.

This wasn't a failure of skill; it was a limitation of the system. Traditional atmosphere carburizing is an analog process in a digital world.

Erasing the Variables: The Logic of Vacuum

Vacuum carburizing, or Low-Pressure Carburizing (LPC), isn't just an incremental improvement. It's a fundamental rethinking of the process, starting by creating a perfect, controlled environment.

A Clean Slate

The process begins by placing components inside a sealed chamber and pulling a strong vacuum. This simple step is transformative. By removing virtually all molecules of oxygen and other atmospheric gases, it eliminates the possibility of surface oxidation.

It creates a chemically pure canvas, ensuring the treatment affects only the steel itself, without interference from unwanted variables.

A Digital Recipe for Carbon

Once at temperature, a precise, measured dose of a hydrocarbon gas—typically acetylene (C2H2)—is introduced at very low pressure. The high heat and vacuum cause the gas to decompose efficiently, depositing a uniform layer of carbon atoms on the steel's surface.

This isn't a bulk flood of gas; it's a metered, digital instruction. The "boost-and-diffuse" cycles are programmed, allowing engineers to dictate the exact carbon profile and case depth with astonishing accuracy. The process transforms from a chemical bath into a surgical implantation of atoms.

The Gentle Certainty of Gas Quenching

Perhaps the most elegant innovation is the elimination of the oil quench. The chaotic plunge into a liquid bath is the primary source of distortion in traditional hardening.

Vacuum furnaces replace this with High-Pressure Gas Quenching (HPGQ). An inert gas, like nitrogen or helium, is blasted over the parts at high velocity. The key is that this torrent is perfectly controlled—its pressure, flow, and duration are tailored to the part's geometry. It cools the part rapidly but uniformly, relieving stress instead of creating it. The result is a drastic reduction in distortion, saving countless hours and dollars in post-treatment grinding and straightening.

The Psychology of Predictability

The technical benefits of vacuum carburizing create a profound psychological and operational shift for any engineering team.

From Anxiety to Assurance

When a process is highly variable, engineers must over-compensate. They design with wider tolerances, budget for scrap, and build slack into production schedules to account for unpredictable outcomes.

The digital control and repeatability of a vacuum furnace remove this uncertainty. Every critical parameter is monitored and logged, ensuring every part in every batch receives the exact same treatment. This assurance allows for tighter designs, leaner manufacturing, and a fundamental trust in the process. It replaces the anxiety of variability with the confidence of predictability.

A Cleaner Conscience, A Safer Shop

The operational benefits extend beyond the parts themselves. Vacuum carburizing is an inherently clean technology. There is no open flame, no smoke, no soot-covered parts, and no hazardous quench oil to manage and dispose of.

This creates a safer, healthier, and more professional work environment. It's not just about meeting environmental regulations; it's about building a modern facility that attracts and retains talent. It's an investment in people as much as it is in technology.

The Economics of Precision

While the initial investment in a vacuum furnace system is higher, its value is realized in the total cost of ownership and quality.

When to Invest in Certainty

For low-tolerance components where minor warping is acceptable, traditional methods may suffice. But for high-performance parts with complex geometries—like gears, injectors, or aerospace components—the cost of failure is immense. Here, the precision of vacuum carburizing is not a luxury; it's a necessity.

The "higher cost" is an investment against scrap, rework, and catastrophic field failures.

A Clear Comparison

| Feature | Vacuum Carburizing (LPC) | Traditional Atmosphere Carburizing |

|---|---|---|

| Distortion | Minimal, due to uniform gas quenching | Significant, due to violent oil quenching |

| Process Control | Fully digital, microprocessor-controlled | Analog, relies heavily on operator skill |

| Repeatability | Exceptional; virtually identical results batch-to-batch | Moderate; susceptible to environmental variables |

| Part Cleanliness | Excellent; parts emerge clean and dry | Poor; requires post-process cleaning for soot/oil |

| Environment | Clean, no emissions, no hazardous oil waste | Generates smoke, emissions, and used oil |

| Best For | High-precision, complex, critical parts | Simple, low-tolerance, cost-sensitive parts |

The Right Tools for Modern Engineering

Choosing the right heat treatment method is about aligning the process with the value and performance demands of your components. For engineers pushing the boundaries of design, the control and predictability offered by vacuum carburizing are essential.

Implementing this advanced process requires a furnace system built for precision and reliability. KINTEK's advanced vacuum furnaces provide the robust, customizable platform necessary to achieve these superior results. Engineered for precise control over every stage—from vacuum levels to gas quenching—our systems empower manufacturers to move from the art of approximation to the science of certainty.

To explore how a modern vacuum furnace can eliminate variability and elevate the quality of your components, Contact Our Experts.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

Related Articles

- The Real Reason Your High-Performance Materials Are Failing (And It’s Not the Alloy)

- From Brute Force to Perfect Control: The Physics and Psychology of Vacuum Furnaces

- The Unseen Enemy: How Vacuum Furnaces Redefine Material Perfection

- The Unseen Architect: How Vacuum Furnaces Forge the Future of Composites

- The Physics of Perfection: How a Vacuum Furnace Creates Order from Chaos