An engineer stands over a failed component. The material is correct, the design is sound, but under magnification, microscopic imperfections tell a story of compromise. The component cracked because its internal structure wasn't dense enough. It oxidized because the atmosphere wasn't pure enough.

This isn't a failure of material science. It's a failure of environment. It's the inevitable outcome of forcing a high-stakes, specific process into a generic, one-size-fits-all tool.

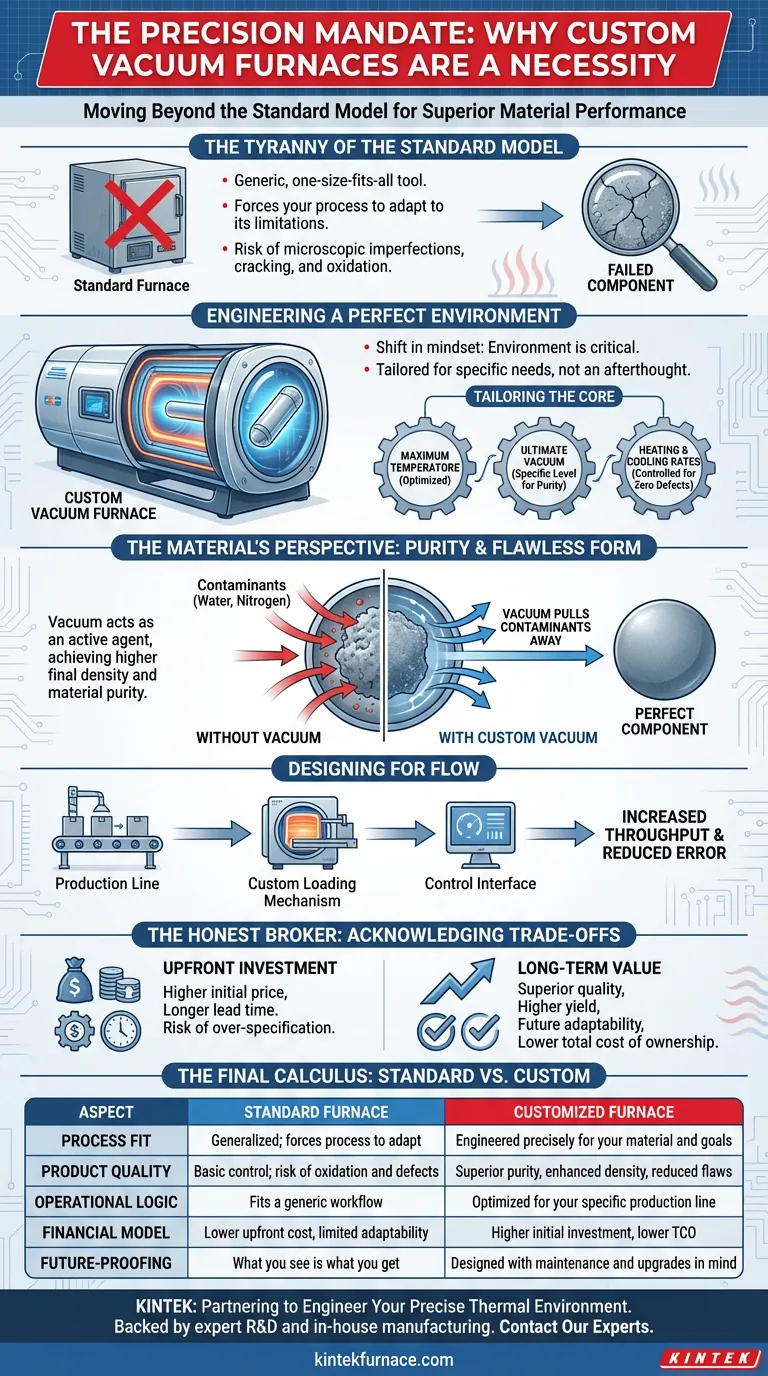

The Tyranny of the Standard Model

Standard, off-the-shelf furnaces are the workhorses of many labs and production lines. They offer a cost-effective, readily available solution for well-understood processes.

But they represent a fundamental compromise. You adapt your process to the machine's limitations, not the other way around. You accept its heating rates, its ultimate vacuum, its physical footprint. This compromise, while often acceptable, becomes a critical liability when pushing the boundaries of material performance.

The psychological trap is thinking of a furnace as just a box that gets hot. In reality, it is the universe in which your creation takes its final, perfect form. And a generic universe yields generic results.

Engineering a Perfect Environment

The decision to specify a custom vacuum furnace is a shift in mindset. It's a declaration that the processing environment is not an afterthought, but the most critical parameter of all. This shift unlocks layers of control and quality unattainable with standard equipment.

From Specification to Perfection: Tailoring the Core

A custom furnace begins with a dialogue, not a catalog. The design is engineered around the precise needs of your material and process.

- Maximum Temperature: Engineered for your target, not a generic range, optimizing heating element life and energy use.

- Ultimate Vacuum: Designed to achieve the specific vacuum level required to prevent oxidation and outgas impurities, ensuring material purity.

- Heating and Cooling Rates: Controlled with precision to prevent thermal shock, reduce stress, and eliminate defects like cracking and deformation.

This is the difference between forcing a material to endure a process and creating the ideal conditions for it to thrive.

The Material's Perspective: Purity and Flawless Form

In the silent, perfect void of a properly specified vacuum furnace, materials transform.

The vacuum itself is an active agent. It pulls harmful contaminants like water and nitrogen away from the material's surface. For processes like sintering, this allows trapped gases to escape, enabling the material to achieve a higher final density. Pores shrink, performance improves, and the risk of internal failure points plummets.

This controlled atmosphere ensures the material you designed is the material you actually produce.

Designing for Flow: Beyond the Chamber

Customization isn't just about what happens inside the furnace. It's also about how the furnace fits into the real world.

The physical footprint, loading mechanisms, and control interface can be designed to integrate seamlessly into your production line. This isn't just a matter of convenience; it's a strategic optimization of workflow, reducing handling time, minimizing human error, and increasing throughput.

The Honest Broker: Acknowledging the Trade-offs

A custom solution is a strategic investment, and every investment requires a clear-eyed assessment of the costs.

- The Upfront Investment: Custom-engineered equipment carries a higher initial price and a longer lead time. This must be weighed against the long-term cost of defects, rework, and lower-quality products.

- The Risk of Over-Specification: It's possible to design a system more complex than necessary. True expertise lies in identifying the essential parameters, not adding every possible feature.

- Supplier Dependency: Service and parts for a unique system are tied to the original manufacturer. This makes choosing a reliable, long-term partner absolutely critical.

The question is not whether a custom furnace is more expensive, but whether the value it creates—through superior quality, higher yield, and future adaptability—justifies the initial investment.

The Final Calculus: Standard vs. Custom

The choice hinges on your strategic goals. A simple table can help clarify the decision matrix.

| Aspect | Standard Furnace | Customized Furnace |

|---|---|---|

| Process Fit | Generalized; forces process to adapt | Engineered precisely for your specific material and goals |

| Product Quality | Basic control; risk of oxidation and defects | Superior purity, enhanced density, and drastically reduced flaws |

| Operational Logic | Fits a generic workflow | Optimized for your specific production line and throughput |

| Financial Model | Lower upfront cost, limited adaptability | Higher initial investment, lower total cost of ownership |

| Future-Proofing | What you see is what you get | Designed with maintenance and future upgrades in mind |

A standard furnace is a tool you buy. A custom furnace is a solution you build. It’s an engineered answer to a specific, critical problem.

At KINTEK, we understand this distinction. Backed by expert R&D and in-house manufacturing, we don't just supply equipment; we partner with you to engineer the precise thermal environment your process demands. Whether it's a Muffle, Tube, Vacuum, or CVD system, our deep customization capabilities ensure your furnace is not a point of compromise, but a source of competitive advantage. To move beyond the limitations of the standard model, Contact Our Experts .

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

Related Articles

- The Alchemy of the Void: How Vacuum Furnace Components Engineer Material Perfection

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- The Physics of Perfection: Deconstructing Temperature Control in a Vacuum Furnace

- Beyond the Heat: The Psychology of Perfect Vacuum Furnace Operation