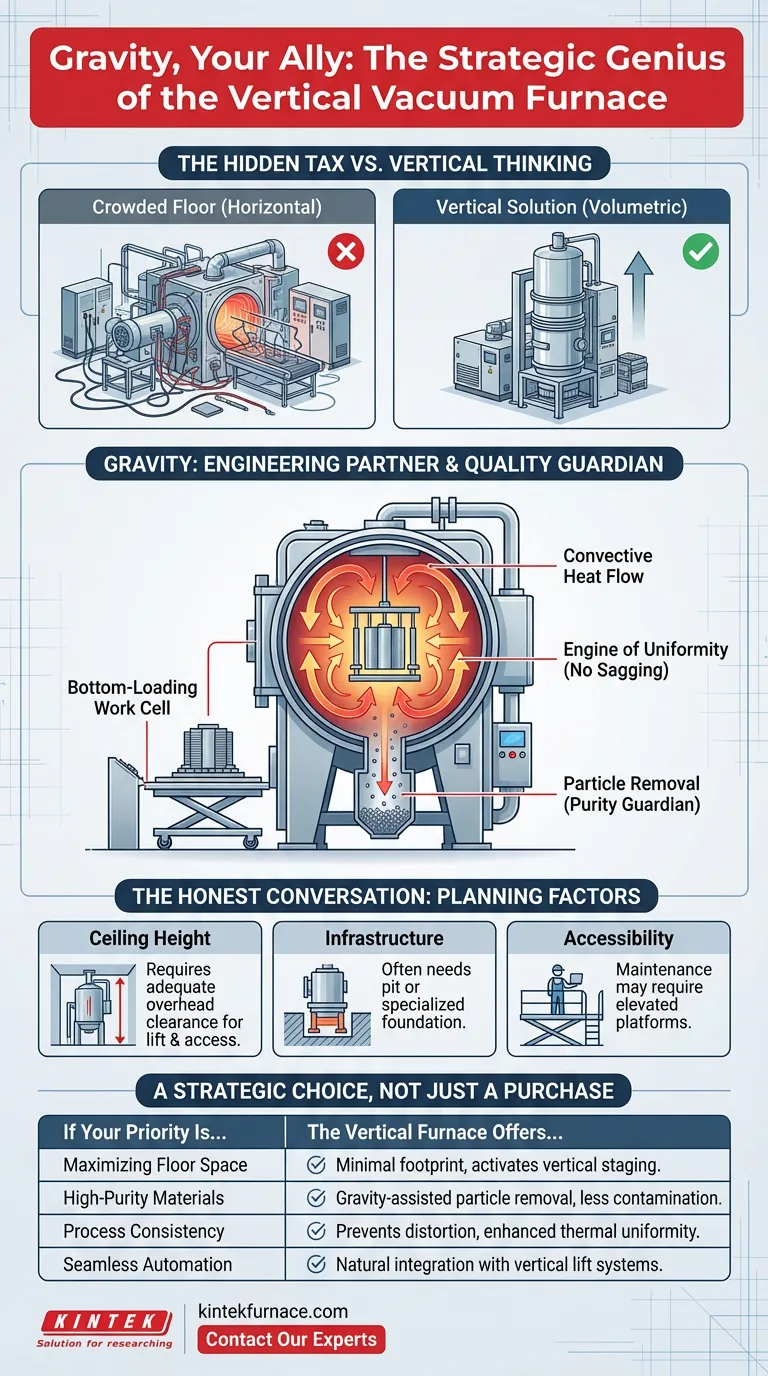

The Hidden Tax of a Crowded Floor

In any advanced manufacturing facility or research lab, floor space is more than just square footage; it's a currency of efficiency. When space is tight, a hidden tax is levied on every process. Teams perform a constant, crowded dance around equipment, material handling becomes a complex puzzle, and the risk of error or contamination subtly increases.

The conventional response is to spread out, to acquire more horizontal space. But a more elegant solution often lies in thinking differently about the space you already have. It requires looking up.

The vertical vacuum furnace embodies this shift in perspective. It's not just a space-saving device; it's a strategic tool that reconfigures your entire operational philosophy.

Thinking in Three Dimensions: Beyond the Footprint

The most obvious benefit of a vertical furnace is its dramatically reduced footprint. By stacking the heating chamber, controls, and vacuum systems vertically, it can occupy a fraction of the floor space of a comparable horizontal model.

But the true genius of the design lies in how it activates a facility's volumetric space.

The Work Cell Below

Most vertical furnaces are bottom-loading. The workload is lifted from below into the hot zone. This simple orientation change is revolutionary. The space directly beneath the furnace is no longer dead space; it becomes a highly efficient staging area.

You can queue the next load, integrate automated transfer systems, or perform preparation tasks in a compact, dedicated work cell. This eliminates the sprawling layout required to stage and load a horizontal furnace, creating a more fluid and linear process flow.

Gravity: The Unsung Engineering Partner

In most engineering challenges, gravity is a force to be managed or overcome. In a vertical furnace, gravity is your most reliable ally. This partnership yields profound benefits for process quality.

An Engine of Uniformity

Gravity ensures a natural and predictable flow of convective heat currents within the vertical chamber. For parts that are suspended, it provides a consistent, gentle pull that can prevent the sagging, warping, or distortion that might occur when a component rests on a flat surface at extreme temperatures.

A Guardian of Purity

Contamination is the enemy of high-purity processes. In a vertical furnace, any microscopic particles generated during a cycle are more likely to fall straight down, away from the product.

Gravity acts as a passive, perfectly reliable cleaning mechanism. This is not a minor feature; for applications in aerospace, medical implants, or semiconductor manufacturing, this inherent cleanliness can be the deciding factor in achieving mission-critical material properties.

The Honest Conversation: Trading Axes

Adopting a vertical system is a strategic trade-off. You are consciously choosing to exchange horizontal sprawl for vertical ambition. This comes with its own set of considerations.

- Ceiling Height: The most obvious requirement is adequate overhead clearance. You need room for the furnace itself, plus the lifting mechanisms and service access.

- Infrastructure: A bottom-loading design often requires a pit or a specialized foundation, adding a layer of complexity to the initial installation.

- Accessibility: Maintenance on a vertically stacked system can be more involved, potentially requiring elevated platforms to access components at the top.

These are not deterrents but rather key planning factors. They represent a commitment to a more integrated, high-density operational model.

A Strategic Choice, Not Just a Purchase

The decision to use a vertical furnace is driven by your primary objective. It’s about aligning the equipment's fundamental design with your process goals.

| If Your Priority Is... | The Vertical Furnace Offers... |

|---|---|

| Maximizing Floor Space | A minimal footprint and the activation of vertical space for staging. |

| High-Purity Materials | Gravity-assisted particle removal, reducing contamination on the product. |

| Process Consistency | Prevention of part distortion and enhanced thermal uniformity. |

| Seamless Automation | A natural integration with vertical lift and transfer systems. |

Choosing the right furnace is a long-term investment in your capability. The geometry of the equipment will define your workflow, your efficiency, and ultimately, the quality of your results for years to come. That's why a one-size-fits-all approach is insufficient.

At KINTEK, our expertise goes beyond standard models. With a deep foundation in R&D and in-house manufacturing, we specialize in customizing high-temperature systems—from Vertical Vacuum and Tube Furnaces to advanced CVD systems—to fit the precise demands of your application. We help you make the strategic choice that best aligns with your goals.

To explore how a tailored furnace solution can redefine your lab's efficiency and performance, Contact Our Experts.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

Related Articles

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- The Alchemy of the Void: How Vacuum Furnace Components Engineer Material Perfection

- The Most Important Number in a Vacuum Furnace Isn't Its Temperature

- Beyond the Void: The Hidden Costs of a Perfect Vacuum Furnace

- The Architecture of Purity: Deconstructing the Vacuum Furnace System