The Unseen Battle Inside the Reactor

Imagine an engineer staring at a multi-story industrial gasifier. It’s a roaring, chaotic inferno, processing tons of biomass per hour. But efficiency is down, and emissions are up. Why? Is it the fuel moisture? An uneven temperature pocket? Turbulent airflow?

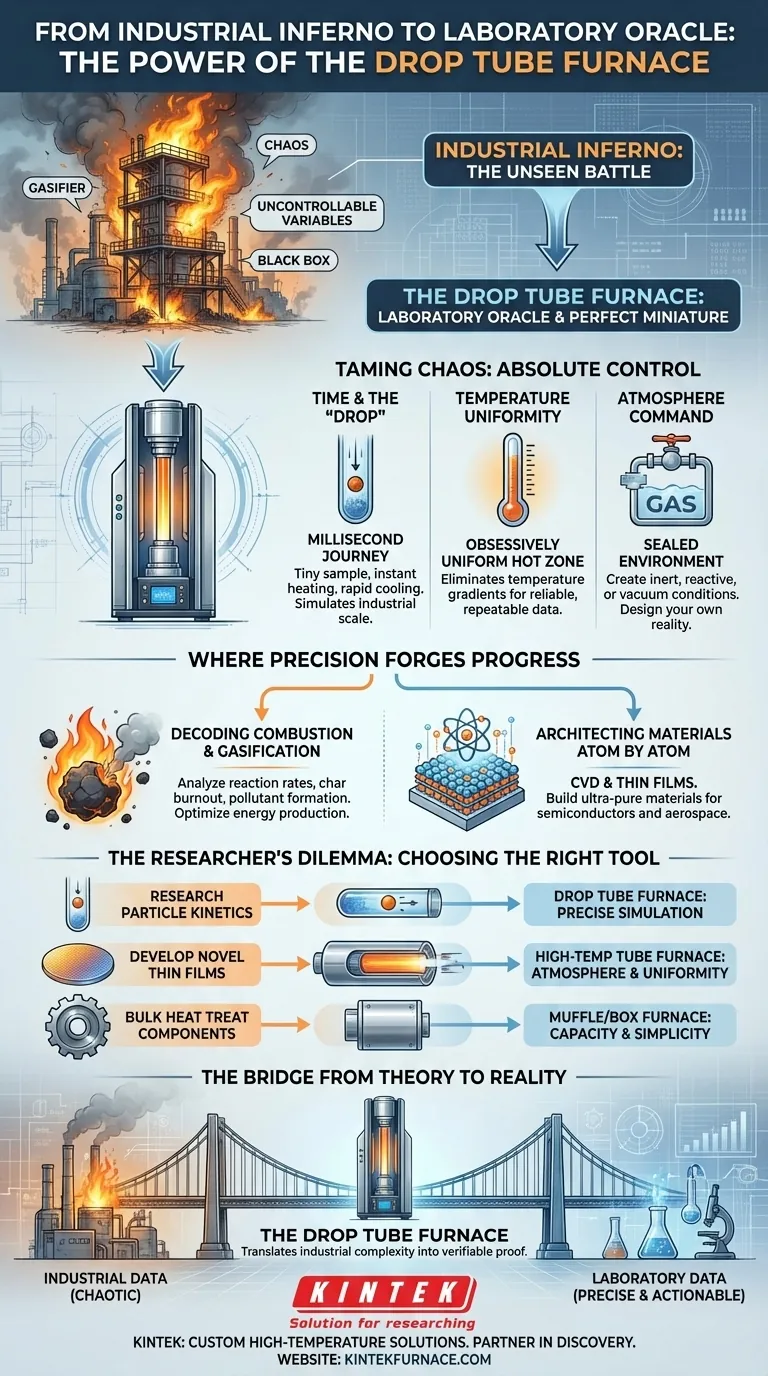

The system is a black box. The sheer scale makes it impossible to isolate a single variable. This is a fundamental psychological challenge in engineering and research: we are driven to understand and control complex systems, but reality often hides the truth in a storm of interacting variables.

To solve the puzzle of the large-scale inferno, you don't build a bigger one. You build a perfect miniature of it.

Taming Chaos: The Principle of Controlled Falling

A drop tube furnace is this perfect miniature. Its design is an act of elegant reduction, built not just to get hot, but to exert absolute control over the three elements that define a thermal process: time, temperature, and atmosphere.

The "Drop": A Millisecond Journey

The core of its function is the "drop." A tiny, measured sample of powdered material—coal, biomass, a new catalyst—is dropped into the top of a vertically oriented, heated ceramic tube.

For a few brief seconds, as the particle falls, it experiences what its counterparts do in a massive boiler: instantaneous, violent heating to a peak temperature, a brief residence time to react, and rapid cooling as it exits the hot zone. It’s an entire industrial process condensed into a single, observable event.

The Pursuit of Perfect Uniformity

Within that hot zone, the temperature isn't just high; it's obsessively uniform. This isn't a trivial detail. It’s the very foundation of reliable data.

By eliminating temperature gradients, the furnace ensures every single particle shares the exact same thermal history. This transforms a chaotic variable into a known constant, allowing researchers to say with certainty that their results are due to the material's properties, not a flaw in the experiment. It removes doubt.

Commanding the Atmosphere

Because the entire process happens inside a sealed tube, the environment is no longer a given; it's a design choice. Researchers can create impossible worlds.

They can conduct pyrolysis in a completely inert, oxygen-free atmosphere to study thermal decomposition in its purest form. They can introduce precise levels of steam and oxygen to perfectly simulate a gasification environment. This control transforms the furnace from a simple heater into a simulator for exploring "what if" scenarios at the heart of R&D.

Where Precision Forges Progress

This ability to perfectly replicate and control extreme conditions makes the drop tube furnace an indispensable tool in several frontier fields.

Decoding Combustion and Gasification

How do you develop cleaner, more efficient energy from solid fuels? You study them particle by particle. By analyzing samples before and after their journey through the furnace, researchers can precisely measure reaction rates, char burnout, and pollutant formation, generating the hard data needed to optimize the massive industrial reactors that power our world.

Architecting Materials Atom by Atom

In processes like Chemical Vapor Deposition (CVD), the goal isn't just to heat a material, but to build a new one. Creating the ultra-pure, high-performance thin films used in semiconductors and aerospace components requires a pristine, high-temperature, and often high-vacuum environment. A tube furnace provides the perfect crucible for depositing functional layers onto a substrate, one atomic layer at a time.

Achieving this level of control requires an instrument built for the task. Customizable furnace systems, such as those engineered by KINTEK, are designed to provide researchers with this exact command over temperature profiles and atmospheric conditions, ensuring the instrument is perfectly matched to the research question.

The Researcher's Dilemma: Choosing the Right Tool

Like any specialized instrument, the drop tube furnace is not a universal solution. Its power lies in its precision, not its throughput. Understanding its boundaries is key to leveraging its strengths.

| Your Objective | The Right Tool for the Job |

|---|---|

| Research particle reaction kinetics (e.g., combustion) | Drop Tube Furnace: The essential tool for simulating industrial reactor conditions with laboratory-level precision. |

| Develop novel thin films or coatings (e.g., CVD) | High-Temp Tube Furnace: Necessary for its absolute control over atmosphere and temperature uniformity. |

| Bulk Heat Treat large solid components | Muffle or Box Furnace: A more practical and cost-effective solution designed for larger capacity and simpler processes. |

The drop tube furnace is a scalpel, not a sledgehammer. Its purpose is to generate pristine data and deep process understanding, not to mass-produce materials.

The Bridge from Theory to Reality

Ultimately, a drop tube furnace serves as a critical translator. It converts the chaotic, impenetrable language of an industrial reactor into the clear, precise, and actionable data of the laboratory. It closes the gap between a hypothesis about how a material should behave and the verifiable proof of how it actually does.

For researchers at the frontiers of materials science and energy, having a furnace that is not just powerful but perfectly adapted to their unique questions is paramount. KINTEK, backed by expert R&D and in-house manufacturing, specializes in engineering these custom high-temperature solutions—from Drop Tube and Rotary Furnaces to complex CVD and Vacuum systems—ensuring your instrument is a true partner in discovery.

To configure the ideal system for your process, Contact Our Experts.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

Related Articles

- The Physics of Control: Mastering the Three-Stage Journey of Heat in a Tube Furnace

- Mastering the Micro-Environment: The Art and Science of the Laboratory Tube Furnace

- Why Your Tube Furnace Is Failing Your Experiments (And It’s Not the Temperature)

- The Art of Isolation: Mastering Material Properties with Tube Furnaces

- Why Your High-Temperature Furnace Fails: The Hidden Culprit Beyond the Cracked Tube