The Unseen Cost of "Good Enough"

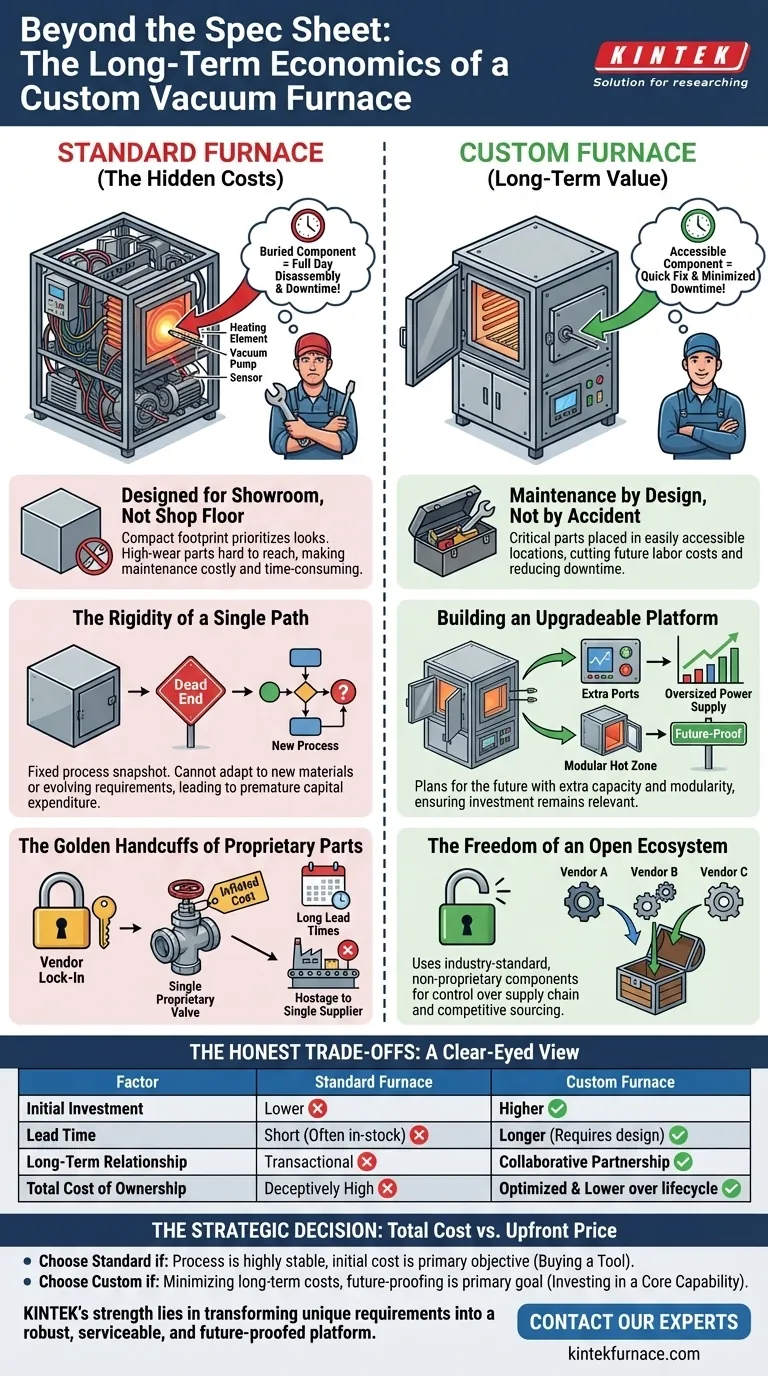

Imagine this: a critical production run is halted. The cause isn't a catastrophic failure, but a simple thermocouple that needs replacing. The problem? It's buried deep within the furnace's chassis, behind three other components, requiring a full day of disassembly by a specialized technician.

This scenario isn't a rare accident. It's a predictable outcome of a system designed for a low sticker price rather than long-term operational sanity.

As humans, we are wired to react to immediate, certain costs—like the purchase price of a piece of equipment. We tend to discount future, uncertain costs, like downtime and complex maintenance. This psychological bias often leads us to choose standard, off-the-shelf equipment that feels like the safe, economical choice.

But the decision to acquire a vacuum furnace isn't just a purchase. It's a strategic investment in your operational capability for the next decade. The real question isn't "what does it cost today," but "what is its total cost of ownership over its entire lifecycle?"

The Hidden Architecture of Failure in Standard Furnaces

Mass-produced furnaces are engineered to a common denominator. This design philosophy, while excellent for minimizing upfront cost, embeds long-term friction and risk into your workflow.

Designed for the Showroom, Not the Shop Floor

Many standard furnaces prioritize a compact footprint to look good on a spec sheet. This often comes at the direct expense of serviceability. High-wear components—heating elements, vacuum pumps, sensors—are crammed into inaccessible locations. Routine maintenance transforms from a quick task into a costly, time-consuming project that bleeds productivity.

The Rigidity of a Single Path

An off-the-shelf furnace is a snapshot in time, built for one defined process. Its chamber size, port configuration, and power supply are fixed. But your needs aren't. When new materials emerge or process requirements evolve, a rigid furnace cannot adapt. It becomes a technological dead end, forcing a new, premature capital expenditure.

The Golden Handcuffs of Proprietary Parts

To protect aftermarket revenue, some manufacturers rely on proprietary components. This vendor lock-in creates a fragile dependency. When a single proprietary valve or controller fails, you face inflated costs, long lead times, and the risk of your entire production line being held hostage by a single supplier's inventory.

Engineering for Evolution: The Customization Philosophy

A custom design process flips the script. Instead of accepting the manufacturer's compromises, you define the terms. This transforms the furnace from a static tool into an adaptable, living platform.

This is the philosophy behind specialized manufacturing. At KINTEK, our R&D-led approach focuses on building equipment that anticipates future needs, not just meets current ones.

Maintenance by Design, Not by Accident

During the design phase, you can mandate that critical components be placed in easily accessible locations. This simple directive is a powerful lever. It acknowledges the reality that parts will wear out and builds a solution for it from day one, drastically cutting future labor costs and minimizing downtime.

Building an Upgradeable Platform, Not a Static Box

A key strategic advantage of customization is planning for the future.

- Extra Ports: Unused, sealed ports can be included for future sensors or gas inlets.

- Oversized Power Supply: A power supply with extra capacity can accommodate a more powerful hot zone later.

- Modular Hot Zone: The chamber can be designed to allow the entire hot zone to be swapped for one with different materials or a higher temperature rating.

This is foresight, engineered. It ensures your investment remains relevant for years to come.

The Freedom of an Open Ecosystem

With a custom build, you can specify the use of industry-standard, non-proprietary components for pumps, valves, and controllers. This grants you control over your own supply chain, ensuring you can source spare parts from multiple vendors at competitive prices.

The Honest Trade-Offs: A Clear-Eyed View

Customization is a strategic choice, and it's crucial to understand the trade-offs involved.

| Factor | Standard Furnace | Custom Furnace |

|---|---|---|

| Initial Investment | Lower | Higher |

| Lead Time | Short (Often in-stock) | Longer (Requires design, fabrication) |

| Long-Term Relationship | Transactional | Collaborative Partnership |

| Total Cost of Ownership | Deceptively High | Optimized and Lower over lifecycle |

The Strategic Decision: Total Cost vs. Upfront Price

The choice between standard and custom hinges on your operational priorities.

- Choose a Standard Furnace if: Your process is highly stable, unlikely to change, and minimizing the initial capital outlay is your absolute primary objective.

- Choose a Custom Furnace if: Minimizing long-term operational costs, reducing production downtime, and future-proofing your investment are your primary goals.

Ultimately, investing in a furnace built by a team of R&D experts and engineers is a decision to take control. It's a shift from thinking about buying a tool to investing in a core capability.

With deep expertise in high-temperature systems from CVD to vacuum furnaces, KINTEK's strength lies in transforming your unique requirements into a robust, serviceable, and future-proofed platform. To build a furnace designed for the long term, Contact Our Experts.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

Related Articles

- Beyond the Batch: How Continuous Vacuum Furnaces Redefine Industrial Metallurgy

- Gravity as an Ally: The Counterintuitive Genius of Vertical Vacuum Furnaces

- The Physics of Perfection: Deconstructing Temperature Control in a Vacuum Furnace

- The Physics of Flawless Production: Why Continuous Vacuum Furnaces Redefine Quality at Scale

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything