It’s a familiar and frustrating scene. You open the furnace after a critical heat treatment cycle, only to find the parts are warped, brittle, or fail to meet metallurgical specifications. Another batch is ruined. Immediately, the search for a cause begins. Was it an operator error? A slight deviation in the material? You spend hours, sometimes days, investigating, trying to pinpoint a mistake that seems impossible to find.

This isn't just a technical problem; it's a costly one that echoes through your entire operation.

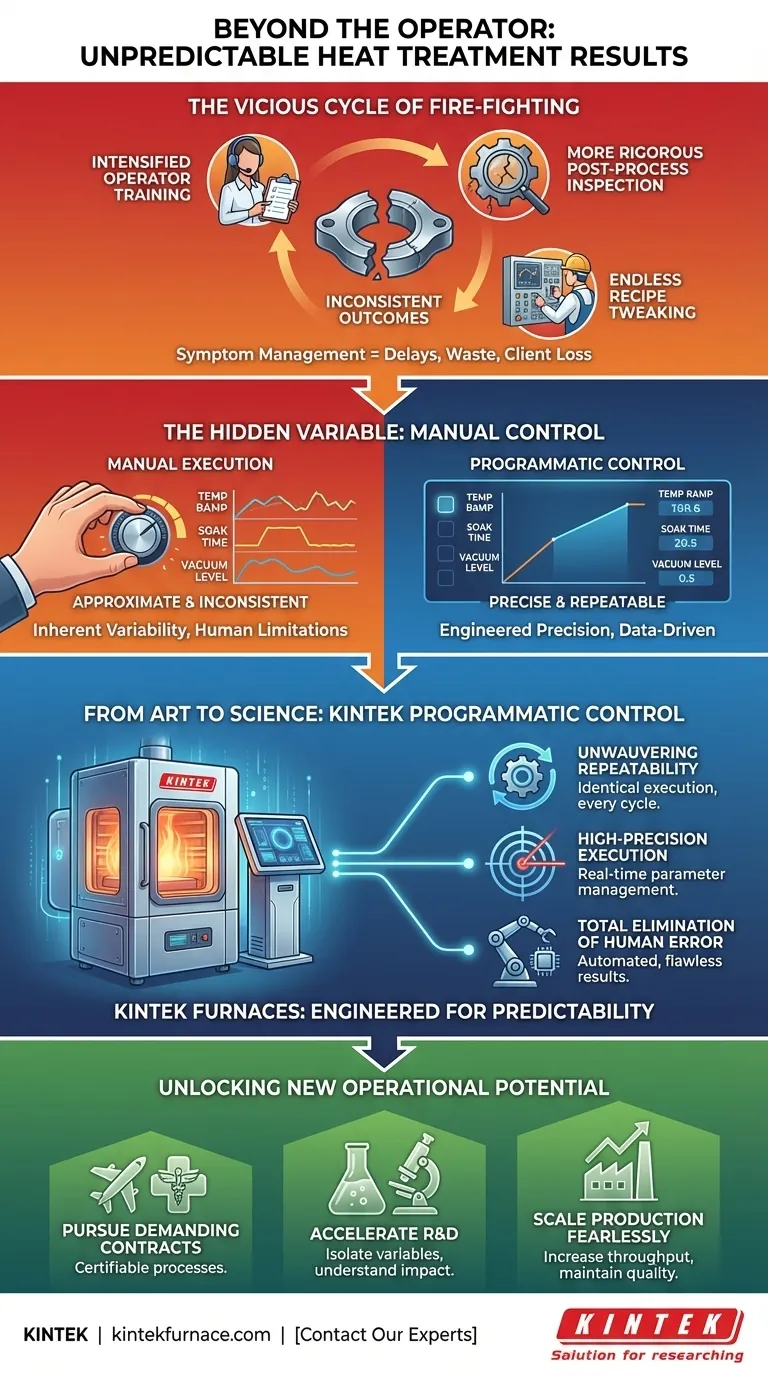

The Vicious Cycle of Guesswork and Firefighting

If you're dealing with inconsistent heat treatment outcomes, you are not alone. It's one of the most persistent challenges in materials science and advanced manufacturing. In response, many labs and production facilities fall into a reactive cycle:

- Intensified Operator Training: Believing human error is the primary cause, teams undergo retraining, and checklists become longer and more complex.

- More Rigorous Post-Process Inspection: To prevent defective parts from reaching customers, you invest more time and resources into quality control, catching failures after they’ve already consumed valuable time and materials.

- Endless Recipe Tweaking: Engineers make small, incremental adjustments to time or temperature, hoping to find a magic formula that works every time.

While well-intentioned, these efforts rarely solve the underlying problem. They are attempts to manage symptoms. This constant firefighting leads to severe business consequences: project delays, budget overruns from scrapped materials, and—most damagingly—a loss of confidence from clients who depend on your reliability.

The Hidden Variable: Why Manual Control Is a Gamble

The core issue is often not the operator or the recipe, but a fundamental limitation of the process itself. The hidden variable sabotaging your results is the inherent inconsistency of manual control.

Think of a complex heat treatment cycle: it involves precise temperature ramps, specific soak times, controlled vacuum levels, and managed gas flows. A skilled operator can follow instructions, but they cannot achieve perfect, micro-second-level precision and identical execution, cycle after cycle.

- A temperature ramp that’s slightly too fast...

- A soak time that’s a few moments too long...

- A vacuum level that fluctuates slightly...

Individually, these deviations may seem minor. But compounded over a multi-hour cycle, they create a different metallurgical outcome. Manual control, no matter how skillful, is an approximation. It treats a precise science like an art form, and the result is unpredictability. This is why retraining and tweaking fail—they don't address the fact that the system itself lacks the capacity for perfect repetition.

From Art to Science: The Power of Programmatic Control

To escape this cycle of inconsistency, you don't need a better-trained artist; you need to transition to a data-driven scientist. The solution is to remove the variable of manual execution entirely. This requires a tool designed not just to get hot, but to execute a complex process with absolute fidelity, every single time.

This is the principle behind a modern, computer-controlled furnace. It’s a system engineered to translate a perfected recipe into a flawless physical result.

KINTEK: Where Precision is Engineered, Not Improvised

At KINTEK, our advanced furnace solutions are built around this philosophy. We don't just sell heating equipment; we provide systems for predictable, repeatable thermal processing. Here’s how our computer-controlled systems directly solve the root cause of inconsistency:

- Unwavering Repeatability: Once your process is programmed, our system executes it identically every single time. It eliminates the subtle, uncontrolled deviations of manual operation, ensuring every batch meets the exact same specifications as the last.

- High-Precision Execution: Our systems manage every critical parameter—from multi-stage ramp rates to precise vacuum pressures—in real-time. This guarantees the material undergoes the exact thermal transformation you designed, not an approximation of it.

- Total Elimination of Human Error: By automating the entire cycle, the system removes the single largest source of process variability. Your best recipe is no longer dependent on who is running the furnace that day.

Our furnaces transform heat treatment from a source of anxiety into a reliable, data-backed manufacturing asset.

Beyond Consistency: Unlocking New Operational Potential

When you are no longer fighting inconsistency, your team's energy and resources are freed up for higher-value work. Achieving predictable results is not the end goal; it's the beginning of a new chapter of innovation and growth.

With the confidence that every cycle will perform exactly as planned, you can now:

- Pursue Demanding Contracts: Confidently serve clients in mission-critical industries like aerospace, medical, and defense, where process certification and data logging are non-negotiable.

- Accelerate R&D: Systematically test new materials and processes, knowing that the furnace's execution is a constant, allowing you to isolate and understand the true impact of your variables.

- Scale Production Fearlessly: Increase throughput without increasing your defect rate. Reliable automation allows you to grow your operations efficiently and predictably.

Ultimately, solving the problem of inconsistency isn't just about reducing scrap. It’s about building a more resilient, innovative, and profitable operation.

Your heat treatment process should be a cornerstone of your quality promise, not a source of constant uncertainty. If you're ready to move beyond firefighting and transform your thermal processing into a strategic advantage, our team is here to help design a solution tailored to your exact needs. Let's discuss your specific material challenges or production goals. Contact Our Experts.

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

Related Articles

- The Hidden Flaw in Your Heat Treatment: It’s Not the Temperature, It’s the Air

- Your Lab Furnace Is Burning Money. Here's the Hidden Design Flaw (And How to Fix It).

- Why Your High-Temperature Furnace Fails: It’s Not the Heating Element, It’s the Physics

- The Invisible Contaminant: Why Your Furnace Atmosphere is Sabotaging Your Results

- Why Your High-Temperature Experiments Fail: It’s Not the Heat, It’s the Atmosphere