The Illusion of a Stable System

A vacuum furnace, from a distance, appears to be a model of stability: a sealed, controlled box where heat transforms materials with precision. But this stability is an illusion.

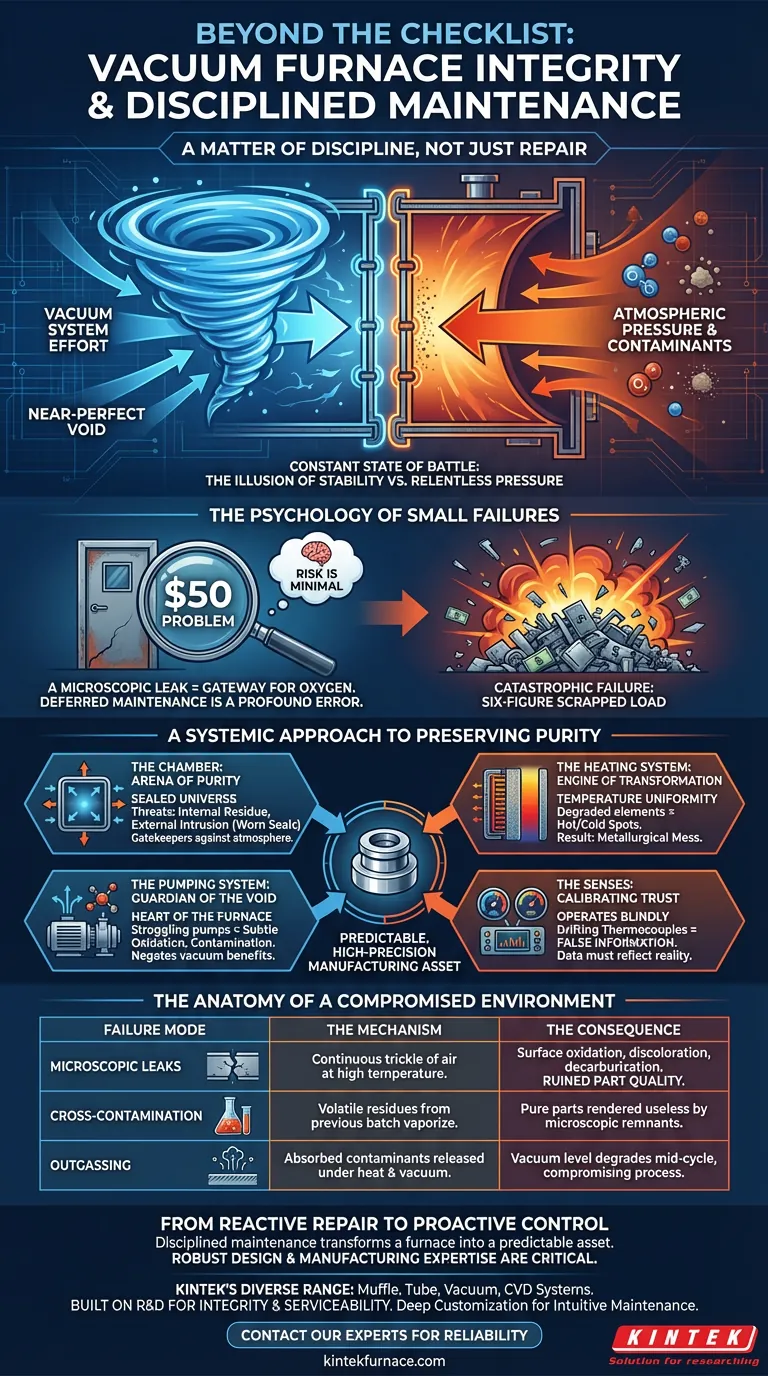

In reality, it's a system in a constant state of battle. On one side, the relentless effort of the pumping system to create a near-perfect void. On the other, the immense pressure of the earth's atmosphere trying to force its way in, carrying with it the oxygen and contaminants that are the sworn enemy of metallurgical purity.

Maintenance, therefore, is not merely a janitorial task or a repair checklist. It is the disciplined, continuous reinforcement of the barriers that hold this chaos at bay. It is the practice that preserves the furnace's entire reason for being.

The Psychology of Small Failures

We have a cognitive bias that makes us underestimate high-impact, low-probability events. We see a slightly worn door seal and calculate the small cost of a replacement part. We defer the task, believing the risk is minimal.

This is a profound error in judgment.

That worn seal isn't a $50 problem. It is a potential gateway for a catastrophic failure. A microscopic leak, imperceptible to the naked eye, can introduce just enough oxygen to compromise an entire batch of high-value aerospace or medical components. The true cost of that deferred maintenance isn't the price of the seal; it's the six-figure value of the scrapped load.

Disciplined maintenance is about overriding this psychological flaw. It's about treating small points of failure with the gravity they deserve, because in a high-vacuum, high-temperature environment, there are no small problems.

A Systemic Approach to Preserving Purity

A furnace isn't a single entity but a collection of interconnected systems. The failure of one directly impacts the integrity of the whole. A robust maintenance plan acknowledges this, treating each component as a critical link in the chain.

The Chamber: The Arena of Purity

Think of the chamber as a sealed universe where your process unfolds. Its integrity is paramount. The primary threats are twofold:

- Internal Contamination: Residue from a previous cycle—like brazing flux—can vaporize in the next, becoming a "ghost in the machine" that contaminates a sensitive new load.

- External Intrusion: Worn seals on doors, ports, and fixtures are the most common points of failure. They are the gatekeepers against the atmosphere, and their inspection is a non-negotiable ritual.

The Heating System: The Engine of Transformation

Heating elements and insulation are responsible for one of the most critical process variables: temperature uniformity. Degraded elements or cracked insulation create hot and cold spots across the workload.

This is the equivalent of trying to cook a steak with a blowtorch and an ice cube. The result is a metallurgical mess—inconsistent grain structures, uneven hardness, and unpredictable performance. Inspecting these components ensures every part in the load receives the exact same thermal experience.

The Pumping System: The Guardian of the Void

The vacuum pumps are the heart of the furnace, tirelessly working to expel molecules and maintain the void. Whether using oil-sealed or dry pumps, their performance is vital.

A struggling pump doesn't just extend cycle times; it may fail to reach the deep vacuum levels required for highly sensitive alloys. This leads to subtle oxidation and contamination, negating the benefits of vacuum processing entirely. Regular checks of oil, filters, and performance are fundamental.

The Senses: Calibrating Trust

A furnace operates blindly, relying entirely on its sensors. Thermocouples measure temperature, and gauges measure vacuum. If these instruments are not calibrated, the entire process is based on false information.

You might think you are running a cycle at 1200°C, but a drifting thermocouple could mean the actual temperature is 1175°C, placing the entire batch outside its required parameters. Calibrating these "senses" is about ensuring that the data you trust is a true reflection of reality.

The Anatomy of a Compromised Environment

While mechanical breakdowns are possible, the most insidious failures stem from a loss of vacuum integrity.

| Failure Mode | The Mechanism | The Consequence |

|---|---|---|

| Microscopic Leaks | A tiny crack in a seal or weld allows a continuous trickle of air into the chamber. | At high temperatures, this oxygen causes surface oxidation, discoloration, and decarburization, ruining part quality. |

| Cross-Contamination | Volatile residues from one batch (e.g., oils, binders, flux) vaporize and deposit onto the next. | A batch of pure titanium parts can be rendered useless by the microscopic remnants of a previous brazing cycle. |

| Outgassing | Contaminants absorbed into the chamber walls or insulation are released under heat and vacuum. | The vacuum level degrades mid-cycle, compromising the process and extending pump-down times. |

From Reactive Repair to Proactive Control

Ultimately, disciplined maintenance transforms a vacuum furnace from a temperamental piece of equipment into a predictable, high-precision manufacturing asset. The foundation for this control begins with the design of the furnace itself.

A system engineered with an intimate understanding of these failure points is inherently more reliable. This is where robust design and manufacturing expertise become critical. KINTEK's diverse range of high-temperature furnaces—from Muffle and Tube to advanced Vacuum and CVD Systems—is built on a foundation of R&D that prioritizes integrity and serviceability. By offering deep customization, we ensure your furnace isn't just a standard product, but a solution tailored to the unique demands of your materials and processes, making effective maintenance more intuitive and successful.

Don't let unseen failures compromise your results. Build your process on a foundation of reliability. Contact Our Experts

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

Related Articles

- The Alchemy of the Void: How Vacuum Furnace Components Engineer Material Perfection

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny

- The Physics of Flawless Production: Why Continuous Vacuum Furnaces Redefine Quality at Scale

- Beyond the Void: The Hidden Costs of a Perfect Vacuum Furnace

- The Most Important Number in a Vacuum Furnace Isn't Its Temperature