The Bottleneck on the Factory Floor

Imagine a factory producing thousands of complex metal parts daily. The process is flawless, the materials are perfect, but a single, glaring bottleneck persists: the furnace.

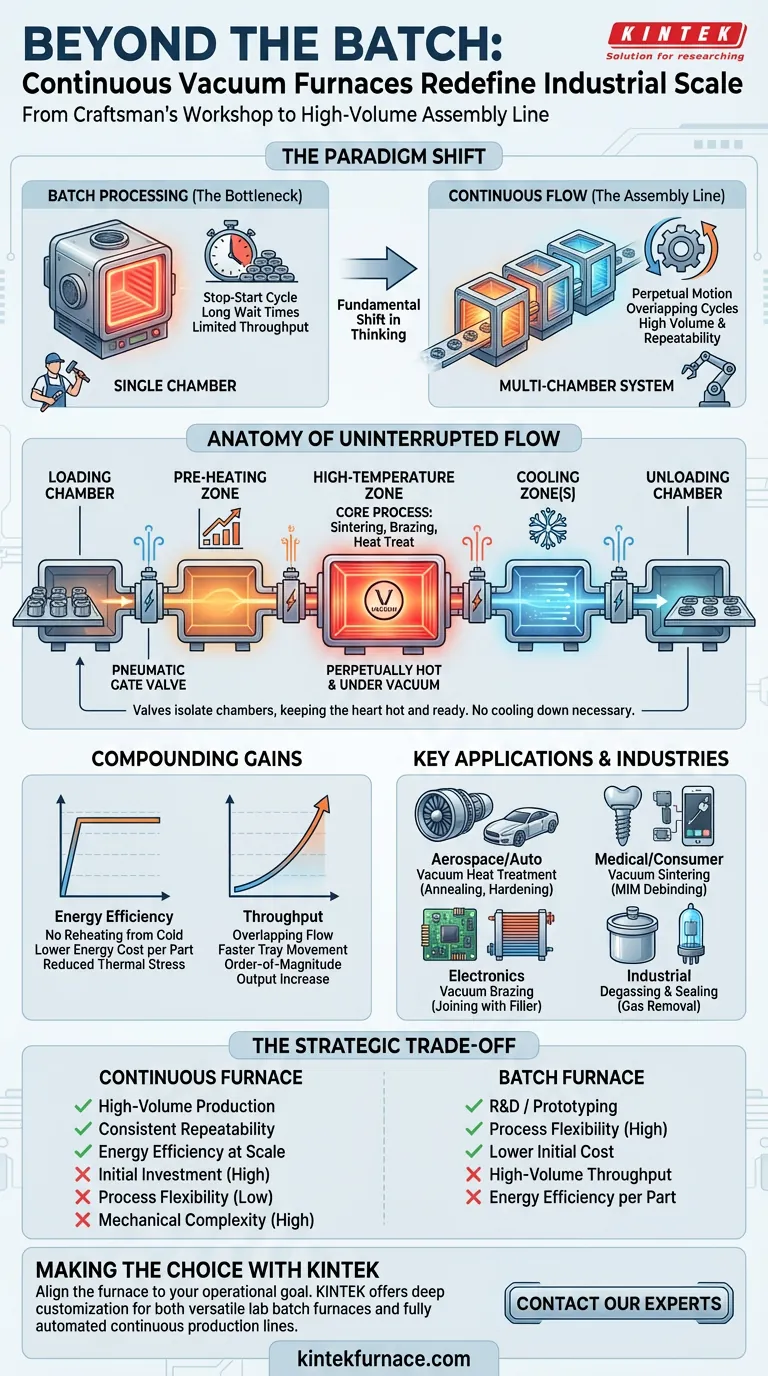

Every cycle—loading, pumping to vacuum, heating, soaking, cooling, and unloading—happens in one chamber. While that chamber is occupied for hours, the rest of the production line waits. This isn't a failure of the furnace; it's a failure of the paradigm. It's the inherent limit of batch processing when ambition meets scale.

This is a common psychological trap in manufacturing: we optimize the steps we know, rather than reimagining the entire flow. The move to a multi-chamber continuous furnace isn't just an equipment upgrade; it's a fundamental shift in thinking.

The Mental Model Shift: From Batch to Continuous

A single-chamber batch furnace is like a workshop for a craftsman. It's versatile, precise, and perfect for unique or low-volume jobs.

A multi-chamber continuous furnace is an assembly line. It’s an admission that you’re no longer crafting one-offs. You are manufacturing at scale, and the governing principle must change from flexibility to flow. This decision is a strategic bet on volume and repeatability.

It requires the conviction to trade the jack-of-all-trades agility of a single chamber for the relentless, optimized throughput of a specialized system.

Anatomy of an Uninterrupted Flow

So, how does a continuous furnace break the cycle? By breaking the process into a sequence of dedicated, interconnected modules.

The Assembly Line for Heat

A typical system segments the thermal journey:

- Loading Chamber: Parts enter the system without disturbing the main process.

- Pre-heating Zone: Parts are gradually brought to temperature, improving efficiency.

- High-Temperature Zone: The core process—sintering, brazing, or heat treatment—occurs.

- Cooling Zone(s) : Parts are cooled in a controlled manner.

- Unloading Chamber: Finished parts exit, again without breaking vacuum in the core.

The Elegance of Isolation

The true engineering magic lies in the pneumatic gate valves separating each chamber. These valves allow a tray of parts to move from one stage to the next while ensuring the central high-temperature zone remains perpetually hot and under deep vacuum.

The heart of the furnace never has to cool down. It exists in a state of constant readiness.

The Compounding Gains of Perpetual Motion

This design doesn't just make the process faster; it makes it fundamentally more efficient.

Escaping the Thermal Cycle Trap

A batch furnace wastes enormous energy reheating its chamber from a cooled state for every new load. It’s like stopping and starting a massive engine for every single delivery. A continuous furnace keeps the engine running hot, dramatically lowering the energy cost per part and reducing thermal stress on critical components like heating elements and insulation.

Redefining Throughput

Throughput is no longer dictated by the longest single thermal cycle. It's dictated by how quickly you can move trays through the system. While one batch is being heated, another is cooling, and a third is being loaded. The process becomes a constant, overlapping flow of material, often increasing output by an order of magnitude.

Where Continuous Flow Becomes Essential

This approach is the backbone of several high-volume industries that depend on the pristine environment a vacuum provides.

| Application | Key Processes | Primary Industries |

|---|---|---|

| Vacuum Heat Treatment | Annealing, Hardening, Tempering | Aerospace, Automotive |

| Vacuum Sintering | Debinding, Sintering | Metal Injection Molding (MIM) |

| Vacuum Brazing | Joining with Filler Metal | Electronics, Heat Exchangers |

| Degassing & Sealing | Gas Removal, Sealing | Vacuum Containers, Electronics |

From hardening aerospace fasteners to sintering the tiny, intricate parts in your smartphone, continuous furnaces make modern mass production possible.

The Deliberate Trade-Off: When Not to Go Continuous

Objectivity demands acknowledging that this is not a universal solution. The power of a continuous system comes with clear trade-offs.

- Higher Initial Investment: These are complex systems and represent a significant capital commitment justified only by high, consistent production volume.

- Reduced Process Flexibility: The system is engineered for a specific thermal profile and part size. It lacks the day-to-day adaptability of a batch furnace used for R&D or highly varied job-shop work.

- Increased Mechanical Complexity: More moving parts—rollers, belts, and multiple valves—mean a more demanding preventative maintenance schedule.

Making the Strategic Choice for Your Goal

The right furnace is the one that aligns with your operational reality and future ambitions.

- For high-volume, repeatable production, a continuous furnace is the logical, definitive endpoint.

- For R&D, prototyping, or small, varied batches, a flexible single-chamber furnace remains the superior tool.

Choosing between them is a defining moment for any manufacturing operation. It requires a partner who understands not just the hardware, but the strategic implications of that choice. KINTEK's expertise in R&D and manufacturing allows for deep customization, ensuring that whether you need a versatile lab furnace or a fully automated continuous production line, the solution is precisely tailored to your goal.

To explore how a custom-engineered furnace can resolve your production bottlenecks, Contact Our Experts.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

Related Articles

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny

- The Physics of Flawless Production: Why Continuous Vacuum Furnaces Redefine Quality at Scale

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- The Architecture of Purity: Deconstructing the Vacuum Furnace System

- In Pursuit of Purity: The Silent Power of the Vacuum Furnace