In high-stakes research and manufacturing, the goal is never just to make something hot. The goal is control.

Anyone can apply brute force to generate heat. The real challenge—the one that separates standard equipment from a precision instrument—is achieving perfect, predictable, and uniform temperature across a three-dimensional object.

This is a battle against thermal chaos. In aerospace, a turbine blade with an uneven heat treatment is a failure. In semiconductor fabrication, a slight temperature gradient can render an entire wafer useless. The psychological drive for this level of control isn't about perfectionism; it's about repeatability and reliability.

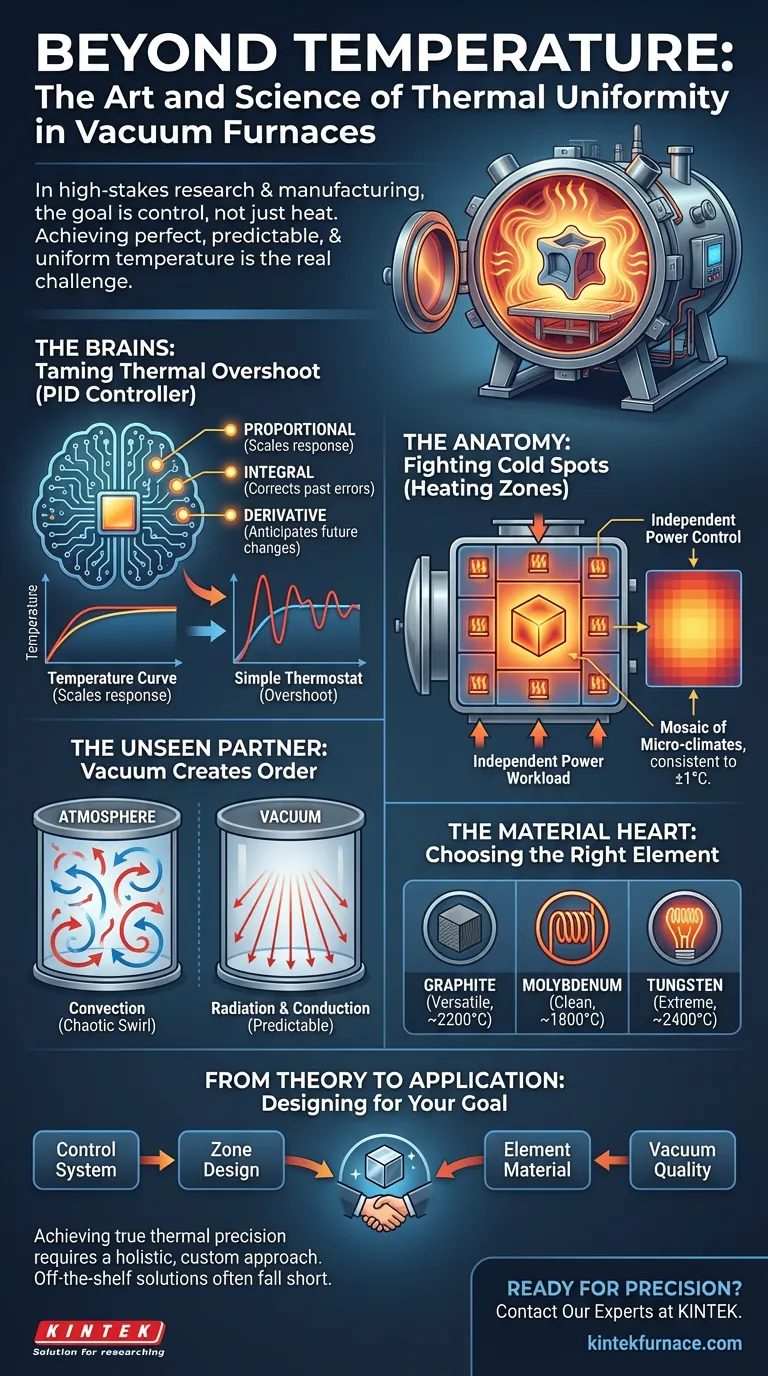

The Brains of the Machine: Taming Thermal Overshoot

At the heart of a modern vacuum furnace lies a sophisticated mind: the PID (Proportional-Integral-Derivative) controller.

Think of a simple thermostat. It turns the heat on when it's too cold and off when it's too hot. This creates a crude wave of temperature fluctuation, constantly overshooting and undershooting the target. This is unacceptable for sensitive processes.

The PID controller is different. It doesn’t just react; it anticipates.

- Proportional: It scales its response based on how far the temperature is from the setpoint.

- Integral: It corrects for any past, cumulative errors, eliminating steady-state deviation.

- Derivative: It anticipates future changes by looking at the rate of temperature change, preventing overshoot.

This constant, high-speed balancing act is like an expert driver feathering the accelerator, maintaining a perfect speed rather than lurching between full throttle and braking. It’s the furnace’s intelligence, ensuring stability.

The Anatomy of Uniformity: Fighting Cold Spots

A furnace chamber is not a thermally monolithic space. The area near the door will always be a little cooler. Corners lose heat differently than the center.

To combat this, a custom furnace is not built with one giant heater. It's divided into multiple, independently managed heating zones.

Each zone has its own power supply, commanded by the central PID controller. The system measures the temperature across the entire chamber and directs more energy to the cooler zones and less to the hotter ones. It treats the chamber not as a single room, but as a mosaic of micro-climates, ensuring the workload experiences a remarkably consistent thermal environment, often to within ±1°C.

The Unseen Partner: How a Vacuum Creates Order

The vacuum itself is a fundamental tool for control. By removing air, you remove a major source of thermal unpredictability: convection.

In a normal atmosphere, heat transfer is a chaotic swirl of hot air rising and cool air sinking. In a vacuum, that chaos is gone. Heat transfer simplifies to two, far more predictable mechanisms:

- Radiation: Heat radiating directly from the elements to the workload.

- Conduction: Heat transferred through direct physical contact.

Removing the atmosphere doesn't just prevent oxidation and contamination; it changes the rules of thermodynamics in your favor, allowing the control system to operate with surgical precision.

The Material Heart: Choosing the Right Element

The choice of heating element is a strategic decision dictated by the specific scientific goal. It's not a one-size-fits-all component.

| Heating Element | Key Characteristics | Typical Max Temp. |

|---|---|---|

| Graphite | Versatile, cost-effective, common for many applications | ~2200°C |

| Molybdenum | Excellent for high-vacuum, clean applications | ~1800°C |

| Tungsten | Used for the most extreme temperature requirements | ~2400°C |

The material must not only reach the target temperature but also be chemically inert to the materials being processed. This choice is a foundational part of the furnace's design, ensuring the instrument is perfectly matched to its mission.

From Theory to Application: Designing for Your Goal

Achieving true thermal precision is a system-level challenge. It requires a holistic approach where the control system, heating zone design, element material, and vacuum quality work in concert. This is why off-the-shelf solutions often fall short for cutting-edge applications.

At KINTEK, we understand that every research goal is unique. Our expertise in R&D and manufacturing allows us to engineer custom Muffle, Tube, Vacuum, and CVD furnace systems tailored to specific process demands. Whether your priority is absolute uniformity for aerospace components or an ultra-clean, high-temperature environment for material synthesis, we design the system around your objective.

Building a furnace that can master temperature is about more than just components; it's about a deep understanding of the interplay between physics and engineering. To achieve truly repeatable results, you need a partner who can navigate these complexities with you.

Ready to bring this level of precision to your work? Contact Our Experts

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

Related Articles

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny

- The Physics of Perfection: Deconstructing Temperature Control in a Vacuum Furnace

- The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection

- The Unseen Architect: How Vacuum Furnaces Forge the Future of Composites