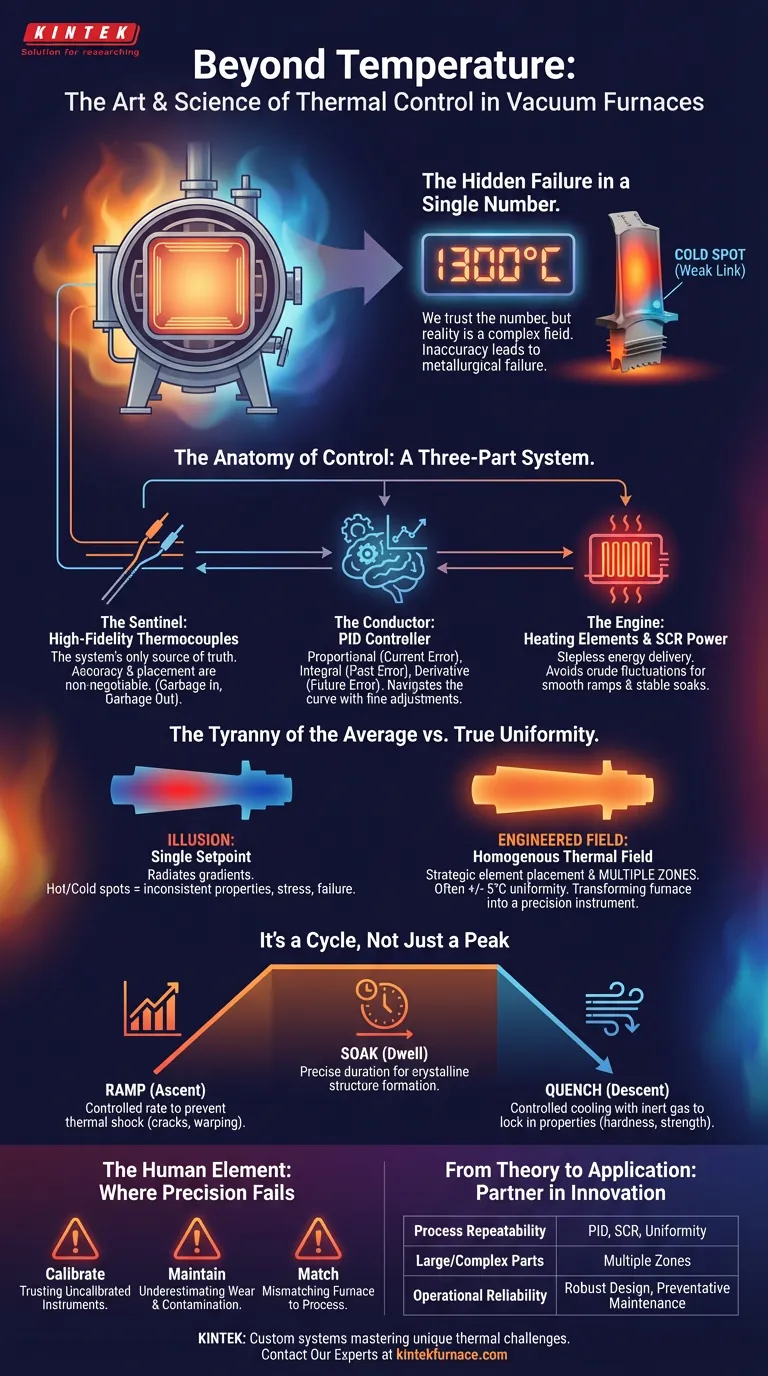

The Hidden Failure in a Single Number

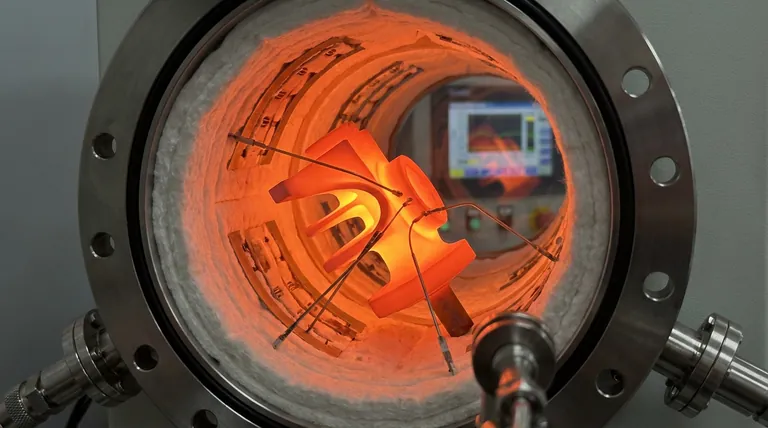

An aerospace component, forged from a superalloy, is designed to withstand incredible stress. Its strength isn't just in its material, but in the history of its atoms—a history written by heat.

During its heat treatment, the furnace display reads a perfect 1300°C. But deep inside the chamber, a cold spot, just a few degrees off, goes unnoticed. A small section of the component never achieves the required metallurgical transformation. It becomes the weakest link.

This is the central challenge of thermal processing. We are psychologically drawn to the single, reassuring number on a control panel, but the reality of heat is a dynamic, three-dimensional field. True mastery lies not in reaching a temperature, but in controlling a complex thermal environment.

The Anatomy of Control: A Three-Part System

A modern vacuum furnace doesn't just "get hot." It operates a sophisticated, closed-loop system—an elegant conversation between sensors, a controller, and heating elements.

The Sentinel: High-Fidelity Thermocouples

The system's only source of truth is its sensors. Thermocouples are the sentinels placed within the hot zone, constantly reporting the ground truth back to the controller.

Their accuracy and placement are non-negotiable. A control system, no matter how intelligent, is blind without reliable data. It operates on the principle of Garbage In, Garbage Out. An inaccurate sensor reading will lead to a perfectly executed, but entirely wrong, thermal cycle.

The Conductor: The PID Controller

The brain of the operation is the PID (Proportional-Integral-Derivative) controller. This isn't a simple on/off switch; it's more like a skilled driver navigating a high-speed curve.

- Proportional: It reacts to the current temperature error.

- Integral: It accounts for past errors, eliminating steady-state drift.

- Derivative: It anticipates future errors based on the rate of change.

This constant calculation allows the controller to make incredibly fine adjustments, preventing overshoots and undershoots and holding a setpoint with unwavering stability.

The Engine: Heating Elements & SCR Power

The muscle is provided by the heating elements, but their power is managed with finesse. An SCR (Silicon-Controlled Rectifier) Power Supply delivers stepless, precise energy to the elements.

This avoids the crude fluctuations of on/off systems, enabling smooth temperature ramps and stable soaks. It is the tool that allows the PID controller's intelligent decisions to become physical reality inside the furnace.

The Tyranny of the Average: Why Uniformity is King

Achieving the correct average temperature is only half the battle. If one side of a part is at 1305°C and the other is at 1295°C, the treatment has failed.

The Illusion of a Single Setpoint

A single temperature reading on a display can create a dangerous illusion of uniformity. In reality, heat radiates, reflects, and creates gradients. These "hot" and "cold" spots result in inconsistent material properties—brittleness in one area, softness in another—creating internal stresses that compromise the entire part.

Engineering the Thermal Field

High-performance vacuum furnaces are meticulously engineered to create a homogenous thermal field, often achieving a temperature uniformity of +/- 5°C or better across the entire workload volume. This is accomplished through:

- Strategic placement of heating elements to ensure even radiation.

- Multiple heating zones, each with its own control loop, to actively balance the temperature across the chamber.

This transforms the furnace from a simple oven into a true precision instrument.

It's a Cycle, Not Just a Peak

Effective thermal control manages the entire journey of the material, not just its time at peak temperature.

The Ascent and the Dwell

The initial ramp rate is controlled to prevent thermal shock, which could crack or warp the material. The subsequent soak period is held for a precise duration to allow the desired crystalline structures to form completely and uniformly.

The Controlled Descent: Quenching

The cooling phase is as critical as the heating. To "lock in" the properties developed during the soak, the vacuum chamber is rapidly backfilled with a high-purity inert gas like nitrogen or argon. This gas quenching process removes heat at a controlled rate, dictating the final microstructure and, therefore, the final hardness and strength of the component.

The Human Element: Where Precision Fails

The most advanced system is still subject to human oversight. Our own cognitive biases are often the biggest threat to repeatable success.

- The Bias to Trust: We instinctively trust our instruments. But thermocouples can degrade. Without regular calibration, we are trusting an uncalibrated witness.

- The Illusion of Stasis: We often underestimate the slow, relentless march of entropy. A tiny leak in a door seal, a buildup of contaminants, or an aging heating element can silently degrade the furnace's performance. Rigorous maintenance isn't a chore; it's a defense against chaos.

- The Mismatch of Ambition and Tool: Using a furnace for a process beyond its specified temperature range or uniformity capabilities is a common mistake, born from a hope that the tool can do more than it was designed for.

From Theory to Application

Matching the furnace's capabilities to your process goals is the key to success.

| Your Primary Goal | Key System Focus |

|---|---|

| Process Repeatability | A responsive PID controller, SCR power regulation, and certified uniformity. |

| Large/Complex Parts | Multiple, independently controlled heating zones to ensure an even thermal field. |

| Operational Reliability | A robust design backed by a rigorous preventative maintenance schedule. |

Understanding these principles elevates heat treatment from a black box process to a field of precise material engineering. The furnace is not just a tool, but a partner in innovation.

At KINTEK, we specialize in building these partners. Our deep R&D and manufacturing expertise allow us to create Muffle, Tube, Vacuum, and CVD furnaces that are not just powerful, but precise. Because we understand the physics of heat, we can customize every system to master the thermal challenges unique to your research or production. Contact Our Experts

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

Related Articles

- The Physics of Control: Inside the High-Temperature World of a Tube Furnace

- Why Your Tube Furnace Is Failing Your Experiments (And It’s Not the Temperature)

- The Bottleneck is the Cooldown: How Split Tube Furnaces Redefine Lab Efficiency

- The Unsung Hero of the Lab: The Deliberate Design of the Single-Zone Split Tube Furnace

- More Than a Dial: The Psychology of Precision in Tube Furnace Control