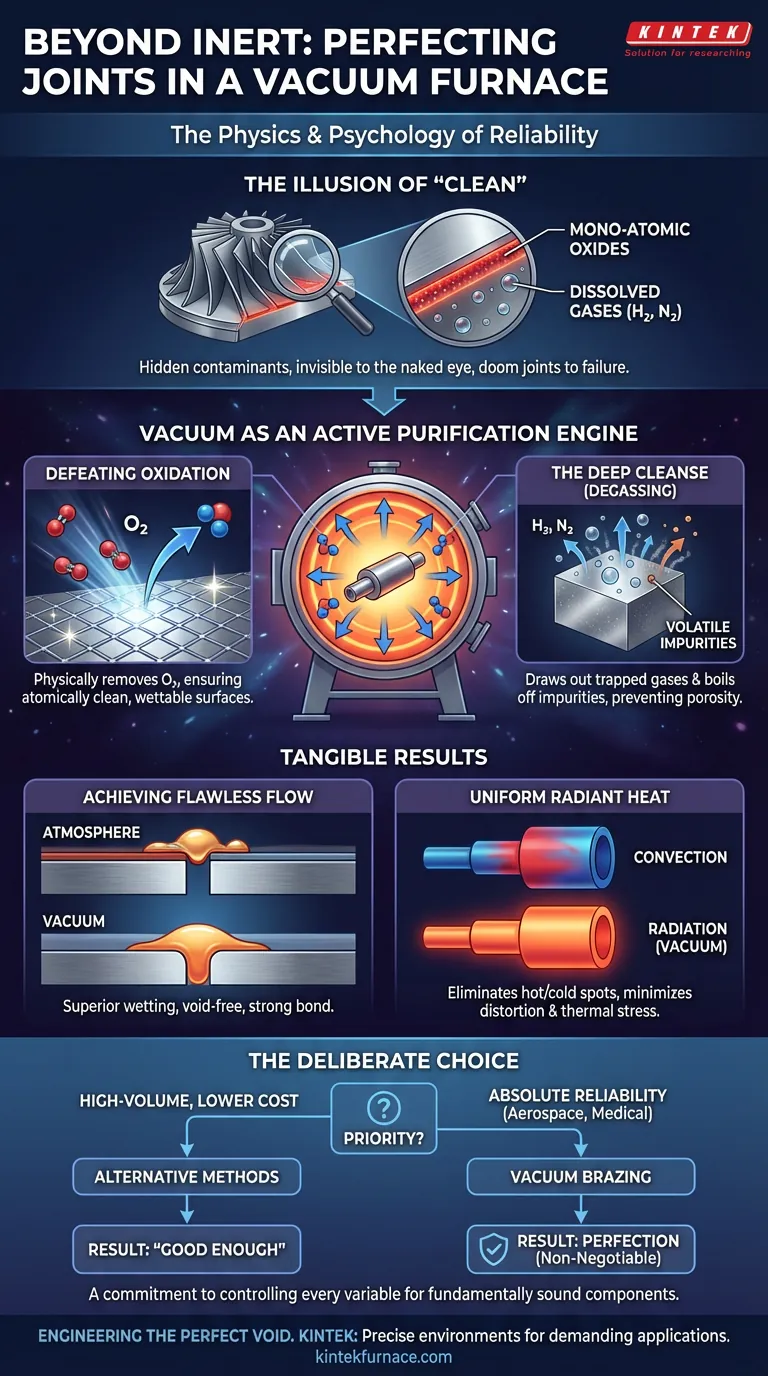

The Illusion of "Clean"

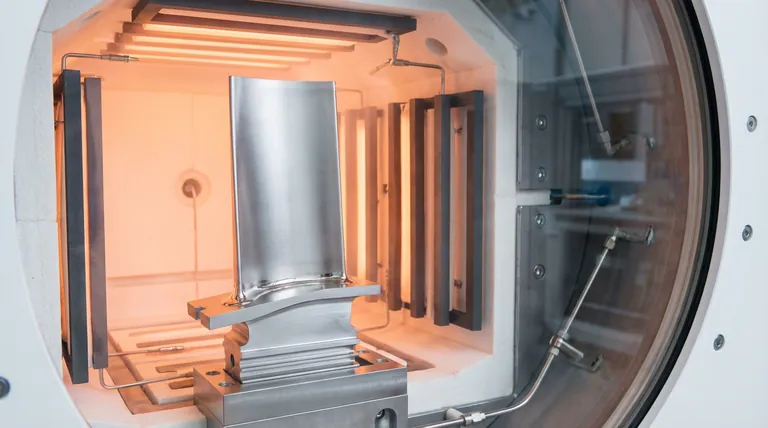

Imagine a critical turbine blade for a jet engine. To the naked eye, the components are flawless, machined to microscopic tolerances and cleaned meticulously.

Yet, lurking on their surfaces is an invisible enemy: a mono-atomic layer of oxides. Trapped within the metal's very structure are dissolved gases. These are the unseen contaminants that, under the intense heat of brazing, can doom a joint to premature failure.

In high-stakes engineering, what you can't see is often what matters most. The decision to braze in a vacuum is a psychological one; it's an admission that conventional "cleanliness" is not enough and a commitment to achieving metallurgical perfection.

Vacuum as an Active Purification Engine

A common misconception is that a vacuum is a passive, empty space. In reality, a high-temperature vacuum furnace is an aggressive, active purification system. It doesn't just build a wall against contamination; it actively rips it out of the environment and the materials themselves.

Defeating Oxidation at the Source

Oxygen is the primary antagonist in brazing. It creates oxide films that act like a non-stick coating, preventing the molten filler metal from "wetting" and bonding with the parent materials. It’s like trying to apply adhesive to a dusty surface.

A vacuum doesn't just displace oxygen like an inert gas would. It physically removes the oxygen molecules, ensuring the metal surfaces remain atomically clean and ready to form a perfect, continuous bond.

The Deep Cleanse: Degassing and Vaporization

Metals are like sponges for gases like hydrogen and nitrogen. Under the low-pressure environment of a vacuum, these trapped gases are drawn out of the material. This degassing is critical for preventing porosity and brittleness that compromise the joint's mechanical strength.

Furthermore, the low pressure reduces the boiling point of many surface impurities. The furnace effectively "boils off" volatile contaminants, performing a final purification step that leaves the parent materials fundamentally cleaner than when they went in.

The Tangible Results of an Intangible Environment

This surgically clean environment directly translates into superior physical properties and unmatched reliability. The benefits are not theoretical; they are measurable improvements in joint integrity.

Achieving Flawless Flow: The Art of Wetting

With no oxide barriers, the molten filler metal flows freely into the joint gap, pulled by the irresistible force of capillary action. This superior wettability ensures a void-free, fully dense joint with maximum contact area, which is the bedrock of a strong and dependable connection.

The Gentle Embrace of Radiated Heat

In a vacuum, heat transfers primarily through radiation, not convection. This eliminates the hot and cold spots caused by swirling gas currents. The result is exceptionally uniform heating, which minimizes thermal stress, reduces distortion, and is absolutely essential when joining dissimilar materials with different expansion rates.

The Deliberate Choice: When Perfection is Non-Negotiable

Vacuum brazing is not always the fastest or cheapest method. It is a deliberate choice made when the cost of failure is unacceptably high. The decision hinges on one question: Is "good enough" acceptable, or is perfection required?

| Your Priority | The Inevitable Choice | Why? |

|---|---|---|

| Absolute Reliability (Aerospace, Medical) | Vacuum Brazing | It eliminates the invisible variables that lead to catastrophic failure. |

| Joining Reactive Metals (Titanium, Superalloys) | Vacuum Brazing | The only environment pure enough to prevent brittle intermetallic reactions. |

| High-Volume, Lower-Cost Production | Alternative Methods | Cycle time and cost are prioritized over the ultimate metallurgical purity. |

This choice reflects a mindset. It's a commitment to controlling every variable to produce a component that is not just functional, but fundamentally sound at a molecular level.

Engineering the Perfect Void

The theoretical power of a vacuum is only unlocked by equipment capable of achieving and maintaining it with absolute precision. Creating this perfect void requires a deep understanding of thermodynamics, material science, and process control.

This is where expert engineering and robust manufacturing converge. At KINTEK, we specialize in creating the precise environments necessary for these demanding applications. Our customizable vacuum furnaces, from high-temperature lab systems to advanced CVD platforms, are designed not just to remove air, but to provide the ultimate control over the brazing process. They are the tools for engineers who understand that the path to reliability is paved with precision.

For applications where compromise is not an option, achieving the perfect void is the only path forward. Contact Our Experts

Visual Guide

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

Related Articles

- The Unseen Enemy: How Vacuum Furnaces Redefine Material Perfection

- The Alchemy of the Void: How Vacuum Furnace Components Engineer Material Perfection

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection