The Illusion of Emptiness

We have a deep-seated bias for addition. To make something stronger, we add reinforcements. To make it better, we add features. But in the world of advanced materials, the most powerful transformation often comes from subtraction.

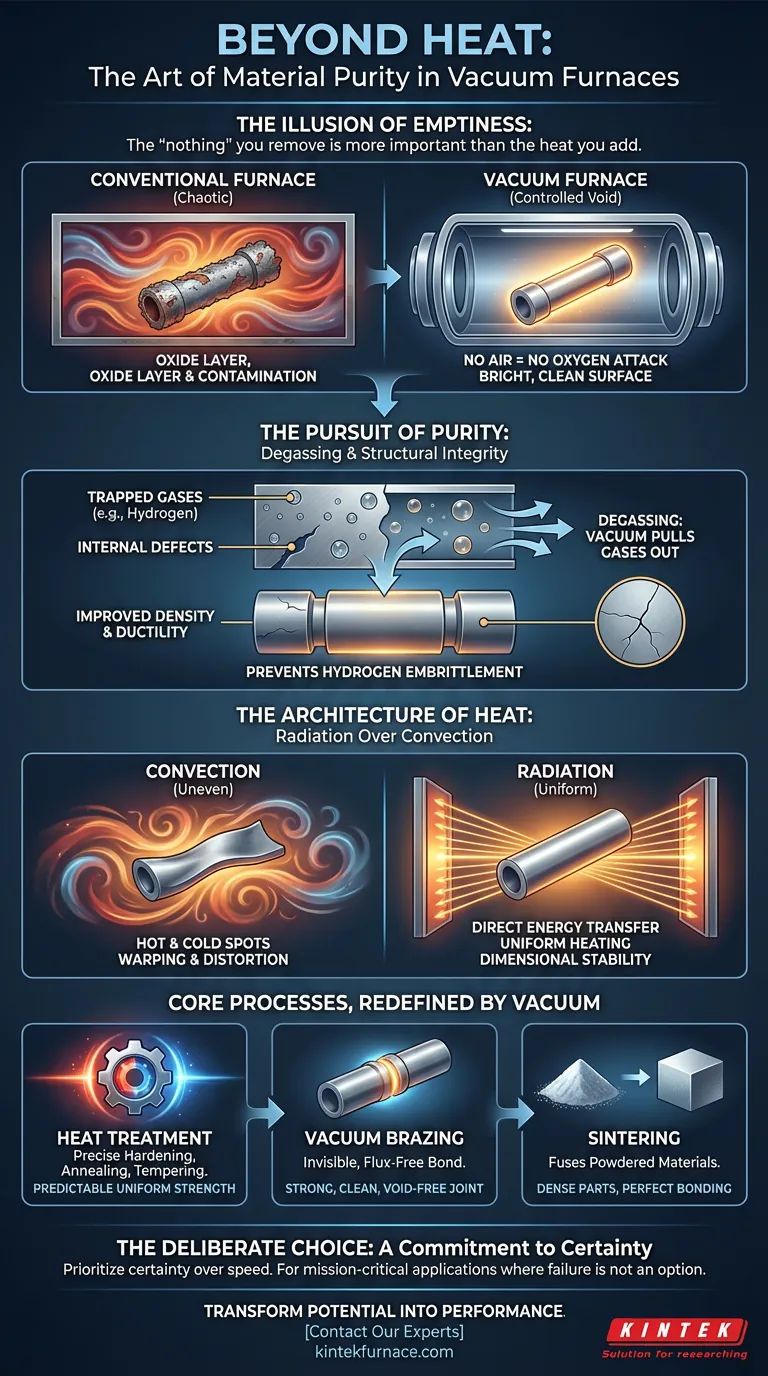

The "nothing" you remove is more important than the heat you add.

This is the central truth of the vacuum furnace. It is not merely a box that gets hot. It is a tool for creating a controlled void—an environment meticulously stripped of the reactive, corrupting influence of the atmosphere. By removing the air, we create the perfect stage for materials to achieve their ultimate potential.

The Enemy in the Air: A Problem of Chemistry

At high temperatures, the air we breathe becomes a powerful adversary. Oxygen, a life-giving gas, aggressively attacks hot metals, forming a brittle, flaky layer of oxide on the surface. It’s the same chemical reaction as rust, but accelerated a thousand times over by heat.

For a blacksmith forging a simple gate, this scale is an acceptable nuisance. For an engineer designing a turbine blade for a jet engine, it is a catastrophic flaw.

A vacuum environment starves this reaction. By evacuating the chamber, we remove the oxygen. The result is a bright, clean surface, free from contamination. This isn't an aesthetic preference; it's a non-negotiable requirement for components where surface integrity dictates performance and safety.

The Pursuit of Purity: Degassing and Structural Integrity

The second invisible enemy lies within the material itself. Microscopic pockets of trapped gases like hydrogen and oxygen, remnants from the material's creation, act as internal defects. Under stress, these pockets can initiate cracks, leading to premature failure in a phenomenon known as hydrogen embrittlement.

Heating a material under vacuum coaxes these trapped gases out. As the atoms vibrate with energy, the vacuum acts like a powerful magnet, pulling the unwanted gas molecules to the surface and out of the chamber.

This process, known as degassing, dramatically increases a material's density, ductility, and fatigue life. It is the difference between a component that might fail and one that is fundamentally sound.

The Architecture of Heat: Radiation Over Convection

In a conventional furnace, heat transfer is a chaotic dance of convection currents. Hot air swirls unevenly, creating hot and cold spots across a component. This thermal inconsistency can cause complex parts to warp, distort, or crack under stress.

A vacuum eliminates convection. Heat is transferred almost entirely through thermal radiation—a direct, line-of-sight energy transfer from the heating elements to the part.

The effect is incredibly uniform heating, as if the component were basking in the light of a miniature sun. This precision is essential for maintaining the dimensional stability of intricate geometries, from medical implants to aerospace assemblies.

Core Processes, Redefined by Vacuum

This absolute control over the environment elevates several key industrial processes from a craft to a science.

Forging Strength Without Flaw: Heat Treatment

Vacuum heat treatment—including hardening, annealing, and tempering—allows metallurgists to precisely manipulate a material's microstructure without the risk of surface decarburization or oxidation. The result is predictable, uniform hardness and strength through the entire part.

The Invisible Bond: Vacuum Brazing

Joining two components with a filler metal in a vacuum creates a bond that is exceptionally strong, clean, and void-free. Without oxygen, there is no need for corrosive flux, which can become trapped and compromise the joint. This is the gold standard for mission-critical assemblies in electronics, medical devices, and aerospace.

Building from Dust: Sintering

Sintering fuses powdered materials into a solid, dense part by heating them below their melting point. In a vacuum, fine metal or ceramic powders are protected from oxidation, allowing their particles to bond perfectly. This is vital for producing hardmetal cutting tools and complex parts via Metal Injection Molding (MIM).

The Deliberate Choice: A Commitment to Certainty

Vacuum furnaces are not a universal solution. They represent a higher initial investment, require more specialized knowledge, and often have longer cycle times due to the need to pump down the chamber.

But this isn't a simple cost-benefit analysis. Choosing a vacuum furnace is a psychological commitment. It is a decision to prioritize certainty over speed, and perfection over convenience. It's for applications where the cost of failure is infinitely higher than the cost of the equipment.

This level of control isn't just a theoretical ideal; it's an engineering reality that requires systems as precise as the processes they enable. For researchers and engineers pushing the boundaries of material science, a customizable furnace is not a luxury—it's a necessity. KINTEK's expertise in developing tailored high-temperature systems, from Vacuum and Atmosphere Furnaces to advanced CVD systems, provides the exact control needed for these demanding applications. Our approach, backed by expert R&D and in-house manufacturing, ensures your equipment is a true partner in achieving material perfection.

If your goal is to transform material potential into guaranteed performance, the first step is creating the perfect environment. Contact Our Experts

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

Related Articles

- The Physics of Flawless Production: Why Continuous Vacuum Furnaces Redefine Quality at Scale

- The Physics of Perfection: Deconstructing Temperature Control in a Vacuum Furnace

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- The Unseen Architect: How Vacuum Furnaces Forge the Future of Composites

- Mastering the Void: How Custom Vacuum Furnaces Forge the Future of Materials