At their core, dental porcelain furnaces are chosen for one fundamental reason: they provide the highly controlled environment necessary to transform ceramic materials into strong, durable, and aesthetically superior dental restorations. This precision over temperature, heating rates, and vacuum is not just a feature; it is the essential requirement for fabricating crowns, bridges, and veneers that meet modern clinical standards.

The decision to use a dental porcelain furnace isn't just about acquiring a piece of equipment. It's about gaining control over a complex material science process, enabling a dental lab or practice to reliably and efficiently produce high-quality, customized restorations that improve patient outcomes.

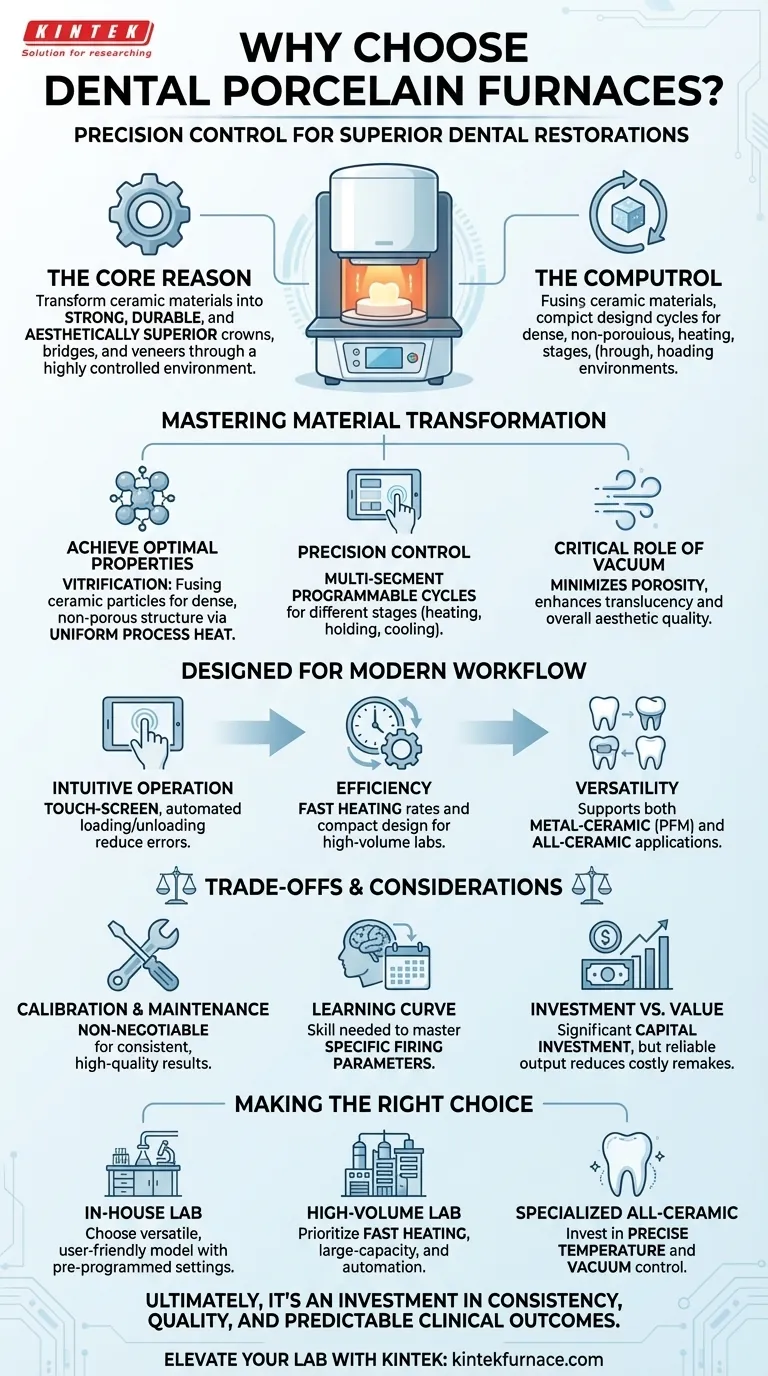

The Core Function: Mastering Material Transformation

A porcelain furnace isn't simply an oven. It is a precision instrument designed to execute complex firing cycles that are critical for the final properties of a ceramic restoration.

Achieving Optimal Material Properties

The entire purpose of firing dental porcelain is to achieve vitrification—the process where ceramic particles fuse together to form a dense, non-porous, and strong structure. This process requires exact temperature control.

A furnace delivers uniform process heat, ensuring the entire restoration vitrifies consistently. This results in ceramic materials that can withstand the demanding conditions of the oral environment.

Precision Temperature and Process Control

Modern furnaces offer multi-segment programmable controllers, often operated via an intuitive touch screen. This allows technicians to define precise firing cycles with multiple stages of heating, holding, and cooling.

This level of control is crucial for different applications, from oxidizing metal substructures to firing dentin and enamel layers, and finally for the stain and glaze firing that produces a natural look. Features like over-temperature protection ensure these cycles run safely and protect the restoration.

The Critical Role of Vacuum

Many firing cycles are performed under a vacuum. Pulling a vacuum (up to 980 mBar in some models) removes air from within the porcelain powder as it heats.

This process minimizes porosity, increases the final density of the material, and significantly enhances the translucency and overall aesthetic quality of the restoration.

Designed for the Modern Dental Workflow

Beyond their core technical function, these furnaces are built to integrate seamlessly into a dental laboratory's operations, focusing on efficiency, versatility, and ease of use.

Intuitive Operation and Automation

Advanced digital controls and touch-screen interfaces dramatically simplify operation. Technicians can easily select pre-programmed cycles for specific materials or create and save custom programs.

Features like a motorized tray for automatic loading and unloading further streamline the workflow, reducing manual handling and potential for error.

Efficiency for High-Volume Work

For labs with heavy or high-volume workloads, efficiency is key. Porcelain furnaces are designed with this in mind, offering fast heating rates to reduce cycle times.

Their compact physical designs also help save valuable floor space in the laboratory without compromising on internal capacity.

Versatility Across Applications

A single furnace can cover a wide range of indications. It is an essential tool for fabricating both metal-ceramic (PFM) and advanced all-ceramic restorations.

This versatility means the furnace is used for sintering, opaque firing, crystallization of pressable ceramics, and final glazing, making it a central and indispensable piece of lab equipment.

Understanding the Trade-offs and Considerations

While essential, selecting and implementing a porcelain furnace requires a clear understanding of the associated factors.

Calibration and Maintenance are Non-Negotiable

To deliver consistent, high-quality results, a furnace must be regularly calibrated. Temperature accuracy can drift over time, impacting the final shade and fit of restorations.

Routine maintenance, including cleaning the muffle (heating chamber) and checking the vacuum pump, is necessary to ensure long-term reliability and performance.

The Learning Curve for New Materials

While the furnace operation itself is often intuitive, mastering the specific firing parameters for the vast array of modern dental ceramics requires skill and knowledge.

Each material has a unique firing schedule provided by the manufacturer. Deviating from these instructions without expertise can lead to failed restorations, making proper training essential.

Initial Investment vs. Long-Term Value

A high-quality dental porcelain furnace represents a significant capital investment. However, its value is realized through its reliability and the quality of the work it produces.

A dependable furnace reduces the rate of costly remakes, increases productivity, and enables a practice or lab to offer a wider range of high-value restorative services, providing a strong return on investment.

Making the Right Choice for Your Goal

Selecting the right furnace depends on your specific operational needs and clinical goals.

- If your primary focus is starting an in-house lab: Choose a versatile, user-friendly model with pre-programmed settings for common materials to simplify the learning curve.

- If your primary focus is maximizing throughput in a high-volume lab: Prioritize furnaces with fast heating rates, large-capacity chambers, and robust automation features like motorized lifts.

- If your primary focus is specializing in complex all-ceramic restorations: Invest in a furnace with the most precise temperature and vacuum control available to ensure optimal aesthetics and material properties.

Ultimately, investing in a dental porcelain furnace is an investment in consistency, quality, and the ability to predictably deliver superior clinical outcomes for your patients.

Summary Table:

| Key Aspect | Description |

|---|---|

| Precision Control | Enables exact temperature, heating rates, and vacuum for optimal material vitrification. |

| Efficiency | Fast heating, automation, and compact design support high-volume workflows. |

| Versatility | Suitable for metal-ceramic and all-ceramic restorations, including sintering and glazing. |

| Aesthetic Quality | Vacuum firing minimizes porosity, enhancing strength, translucency, and durability. |

Elevate your dental lab's capabilities with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, tailored to your unique needs. Our strong deep customization ensures precise fit for applications like dental porcelain firing, improving efficiency and restoration quality. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations