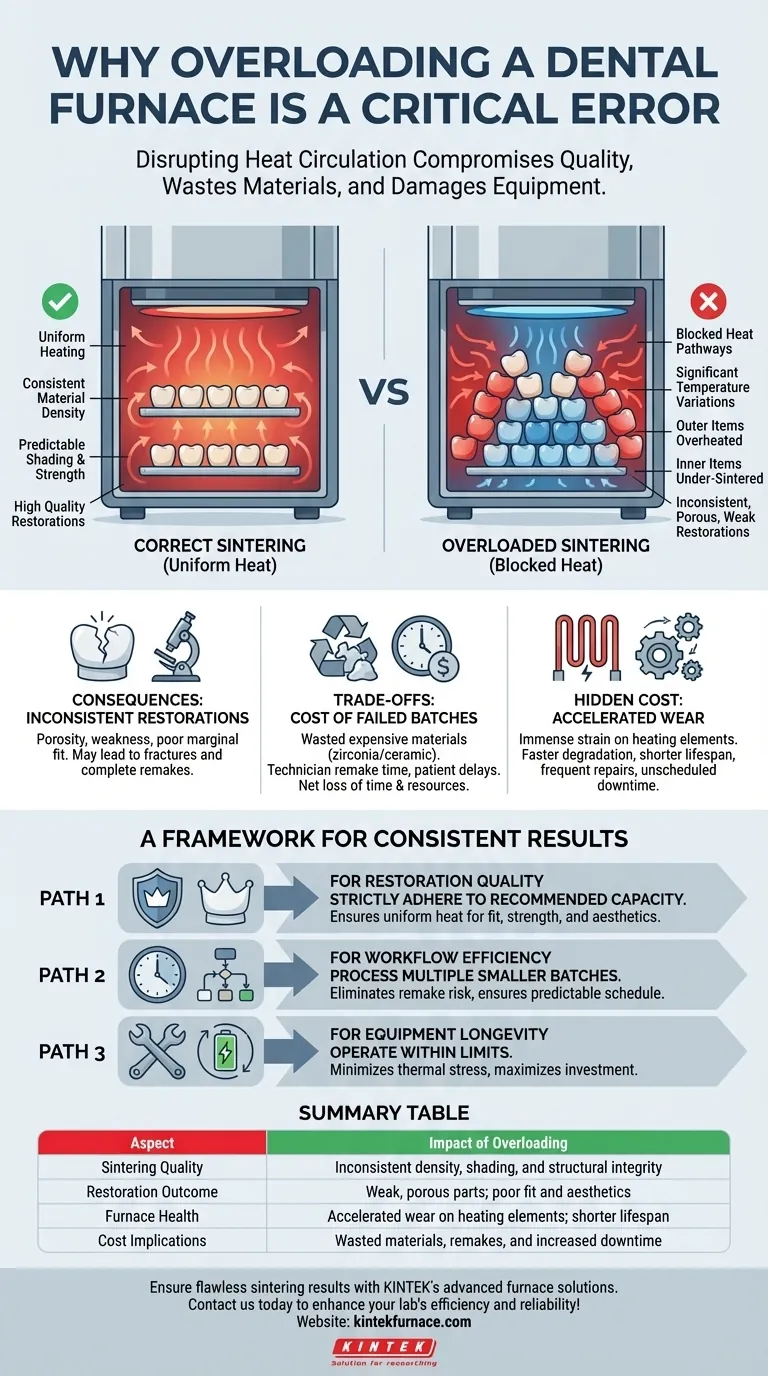

Overloading a dental furnace is a critical operational error because it prevents the uniform heating required for proper sintering. This leads to inconsistent material density, incorrect shading, and compromised structural integrity in the final restoration, ultimately wasting time and expensive materials.

The core issue with overloading is not just about fitting more in; it's about disrupting the fundamental physics of heat circulation. A packed chamber creates cold spots, guaranteeing an uneven sintering process that compromises the quality of the restoration and places unnecessary strain on the furnace itself.

The Physics of Sintering: Why Uniformity is Key

Proper sintering is a process of thermal precision. The goal is to bring the entire restoration, and the entire batch, to a specific target temperature for a set duration, ensuring every part of the material transforms correctly.

How a Furnace Creates a Uniform Environment

A dental furnace is engineered to radiate and circulate heat evenly throughout its chamber. This controlled environment ensures that every surface of a restoration receives the same thermal energy, leading to predictable and consistent material densification, shrinkage, and translucency.

The Impact of Overloading on Heat Circulation

When you overload the chamber, you block the pathways for heat to circulate freely. The items in the center of the mass are shielded by the items on the outside, creating significant temperature variations. The outer crowns may get overheated while the inner ones remain under-sintered.

The Consequences: Inconsistent Restorations

This uneven heating directly results in a failed batch. Under-sintered areas will be porous, weak, and may not achieve the correct shade or translucency. This can lead to fractures under occlusal load or a poor marginal fit, requiring a complete remake of the restoration.

Understanding the Trade-offs: Efficiency vs. Reliability

The desire to process more restorations at once is understandable from an efficiency standpoint. However, this approach creates significant risks that far outweigh the perceived benefits.

The Temptation of the "Full Batch"

It can feel productive to pack the furnace to its physical limit. This is often driven by a desire to save time or energy by running fewer cycles.

The True Cost of a Failed Batch

A single failed batch due to overloading is far more costly than running two separate, successful batches. The cost includes the wasted zirconia or ceramic material, the technician's time for the remake, and potential delays in patient care. The pursuit of speed results in a net loss of time and resources.

The Hidden Cost: Accelerated Wear and Tear

An overloaded furnace must work harder and longer to try and heat the dense, improperly spaced mass. This places immense strain on the heating elements, causing them to degrade faster and shortening their operational lifespan. This leads to more frequent, expensive repairs and unscheduled downtime.

A Framework for Consistent Results

To ensure predictable, high-quality outcomes, you must treat the furnace's load capacity as a strict operational limit, not a suggestion.

- If your primary focus is restoration quality: Strictly adhere to the manufacturer's recommended capacity to guarantee the uniform heat circulation needed for proper fit, strength, and aesthetics.

- If your primary focus is workflow efficiency: Process multiple, smaller batches correctly rather than one overloaded batch. This eliminates the risk of costly remakes and ensures a predictable production schedule.

- If your primary focus is equipment longevity: Operate the furnace within its specified limits to minimize thermal stress on critical components and maximize the return on your investment.

Ultimately, respecting the limits of your equipment is the foundation of achieving consistent, high-quality results.

Summary Table:

| Aspect | Impact of Overloading |

|---|---|

| Sintering Quality | Inconsistent density, shading, and structural integrity |

| Restoration Outcome | Weak, porous parts; poor fit and aesthetics |

| Furnace Health | Accelerated wear on heating elements; shorter lifespan |

| Cost Implications | Wasted materials, remakes, and increased downtime |

Ensure your dental lab achieves flawless sintering results with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Contact us today to enhance your lab's efficiency and reliability!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations