Vacuum quartz tube sealing is a fundamental requirement for the synthesis of ZnPS3 crystals via Chemical Vapor Transport (CVT). It creates a hermetically sealed, high-vacuum environment that physically isolates reactive precursors—specifically zinc foil, phosphorus blocks, and sulfur flakes—from atmospheric oxygen and moisture. This containment is essential for retaining the iodine (I2) transport agent, allowing it to cycle between temperature zones and drive the growth of high-quality single crystals.

The quartz tube acts as a closed thermodynamic system. It preserves the purity of reactive elements by preventing oxidation and maintains the internal pressure required for the transport agent to function effectively.

Establishing a Controlled Chemical Environment

Preventing Precursor Degradation

The raw materials used for ZnPS3—zinc, phosphorus, and sulfur—are highly susceptible to degradation when heated.

Without a vacuum seal, these elements would react immediately with atmospheric oxygen or moisture. This reaction would create unwanted oxides or hydroxides, effectively ruining the purity of the sample before crystal growth can begin.

Ensuring Stoichiometric Precision

To grow a high-quality crystal, the ratio of elements in the final product must match the intended chemical formula.

A sealed environment ensures that no material is lost to the atmosphere or consumed by side reactions. Every atom of zinc, phosphorus, and sulfur introduced into the tube remains available for the synthesis reaction, ensuring the correct stoichiometry is maintained.

Enabling the Chemical Vapor Transport (CVT) Mechanism

Confining the Transport Agent

The CVT process relies heavily on iodine (I2) to act as a transport vehicle.

Iodine reacts with the solid raw materials at the hot end of the tube to form gaseous intermediates. Because iodine creates significant vapor pressure when heated, a robust quartz seal is required to keep this gas contained within the reaction volume.

Facilitating Gas-Phase Circulation

Crystal growth in CVT is driven by a temperature gradient between the "hot" source zone and the "cold" growth zone.

The sealed tube creates a closed loop where the iodine can carry material to the cold end, deposit it as a ZnPS3 crystal, and cycle back to the hot end. If the seal were compromised, this circulation would break, the transport agent would escape, and crystal growth would cease.

Understanding the Trade-offs

Managing Internal Pressure

While sealing provides a necessary closed system, it introduces the risk of over-pressurization.

As the temperature rises, the vapor pressure of sulfur and iodine increases significantly. If the quartz tube is not sealed properly or if the walls are too thin, the internal pressure can cause the vessel to explode.

Technical Complexity of Sealing

Achieving a high-vacuum seal (often below 100 mTorr) requires precise technique.

Improper sealing can induce stress in the quartz glass. This stress becomes a failure point during the heating or cooling phases, potentially destroying the sample after days or weeks of synthesis.

Making the Right Choice for Your Goal

To ensure successful ZnPS3 synthesis, apply these principles based on your specific requirements:

- If your primary focus is Purity: rigorous vacuum evacuation is non-negotiable to remove all traces of oxygen and moisture that could contaminate the sulfur or zinc.

- If your primary focus is Crystal Quality: ensure the tube length and diameter are sufficient to allow steady gas-phase circulation without creating turbulence that disrupts nucleation.

The quartz tube is not merely a container; it is an active component of the thermodynamic system that dictates the success of the crystal growth process.

Summary Table:

| Factor | Role in ZnPS3 Synthesis | Impact of Failure |

|---|---|---|

| Atmospheric Isolation | Prevents zinc, phosphorus, and sulfur oxidation | Contaminated samples and ruined purity |

| Stoichiometry | Maintains exact material ratios within the seal | Unbalanced chemical composition |

| Transport Agent | Confines Iodine (I2) gas for CVT mechanism | Interrupted growth; agent escape |

| Thermodynamics | Creates closed-loop gas circulation | Failed crystal nucleation |

Elevate Your Material Synthesis with KINTEK Precision

High-quality ZnPS3 crystal growth demands a flawless thermal environment and rigorous vacuum integrity. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the exacting standards of Chemical Vapor Transport (CVT). Our lab high-temp furnaces are fully customizable, backed by expert R&D to ensure your quartz tube sealing and heating processes are safe, consistent, and optimized for purity.

Ready to achieve superior crystal quality? Contact our technical experts today to find the perfect furnace solution for your unique research needs.

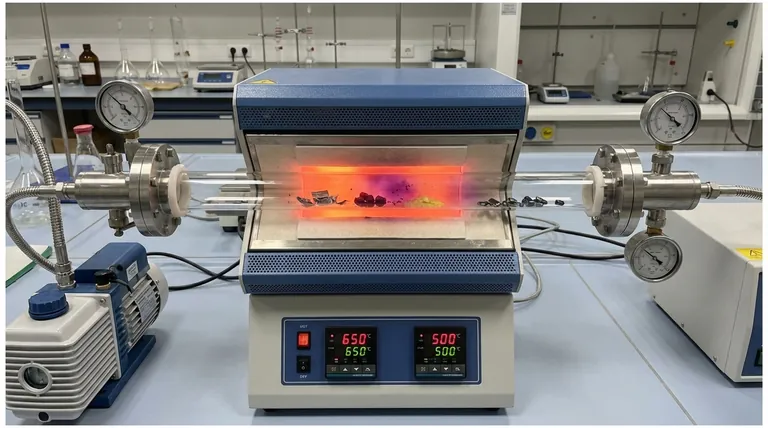

Visual Guide

References

- Abhishek Mukherjee, Svetlana V. Boriskina. Thermal and Dimensional Stability of Photocatalytic Material ZnPS<sub>3</sub> Under Extreme Environmental Conditions. DOI: 10.1002/aelm.202500093

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why are high-purity quartz tubes used in combustion furnaces? Unlock Precise Optical Diagnostics and Purity

- How does the impeller in a water circulating vacuum pump function to create a vacuum? Discover the Liquid Piston Mechanism

- What are the power specifications for a typical circulating water vacuum pump? Key Specs for Lab Efficiency

- What is polycrystalline mullite/alumina wool (PCW) and where is it used? Discover High-Temp Insulation Solutions

- What is the water-saving benefit of using a water circulating vacuum pump? Save Over 10 Tons of Water Daily

- What role does a mechanical vacuum pump system play in cerium dioxide reduction? Boost Efficiency at Lower Pressures

- How does a lab vacuum pump work? Understanding the Liquid Piston Mechanism

- How does a laboratory drying oven contribute to the preparation of C@TiC/SiO2 xerogels? Ensure Structural Integrity