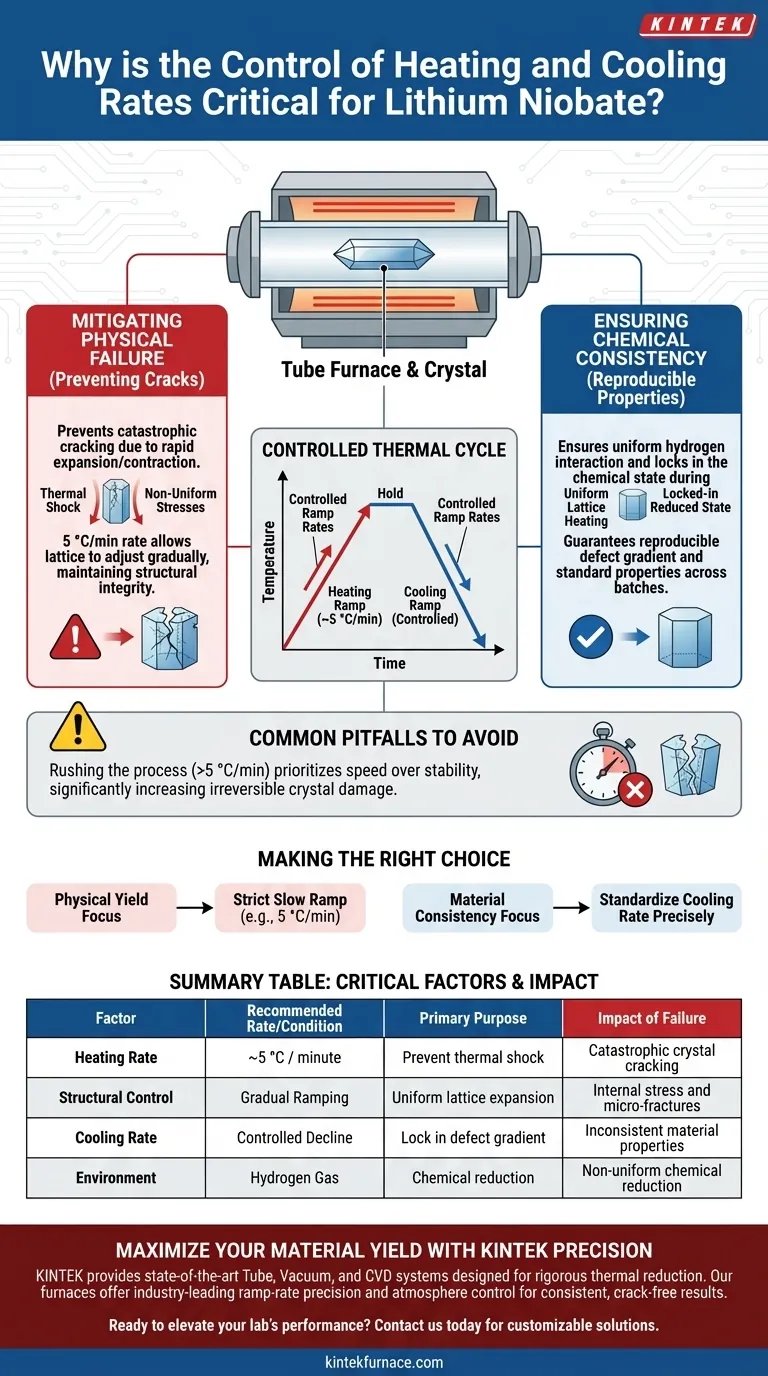

Precise thermal regulation is the absolute foundation of successful lithium niobate reduction. Controlling the heating and cooling rates within a tube furnace—typically around 5 °C per minute—is critical to prevent the crystal from cracking due to severe thermal shock and to ensure the chemical reduction process remains uniform and reproducible.

Regulating ramp rates protects the structural integrity of lithium niobate crystals by preventing thermal shock while ensuring the specific defect gradient distribution is locked in for consistent material properties.

Mitigating Physical Failure

Preventing Thermal Shock

The primary physical risk during thermal reduction is thermal shock. If the temperature changes too rapidly, the crystal cannot expand or contract uniformly.

This disparity creates immense internal pressure. Without strict rate control, this pressure frequently leads to catastrophic cracking, rendering the sample useless.

Eliminating Non-Uniform Stresses

Even if the crystal does not fracture immediately, uncontrolled temperature ramps can induce non-uniform stresses.

These residual stresses compromise the mechanical integrity of the material. A precise rate, such as 5 °C per minute, allows the lattice to adjust gradually, maintaining structural stability.

Ensuring Chemical Consistency

Uniform Lattice Heating

The thermal reduction process typically takes place in a hydrogen environment.

A slow and stable heating profile ensures that the entire crystal lattice reaches the target temperature uniformly. This uniformity is essential for the hydrogen to interact consistentlly with the material structure.

Locking in the Reduced State

The cooling phase is just as critical as the heating phase. Controlled cooling is required to lock in the reduced state effectively.

If cooling is haphazard, the chemical state of the crystal may shift unpredictably as it returns to room temperature.

Reproducibility of the Defect Gradient

For scientific and industrial applications, consistency is paramount.

Strict control over the thermal cycle ensures the defect gradient distribution is reproducible across different batches. This guarantees that the resulting optical and electronic properties remain standard from one run to the next.

Common Pitfalls to Avoid

The Risk of Rushing

The most common error in this process is prioritizing speed over stability.

Accelerating the ramp rate beyond 5 °C per minute significantly increases the probability of irreversible crystal damage. While slower rates extend the total process time, the cost of a failed, cracked sample far outweighs the time savings of a faster ramp.

Making the Right Choice for Your Goal

To achieve optimal results in lithium niobate reduction, tailor your approach based on your specific requirements:

- If your primary focus is Physical Yield: Adhere strictly to a slow ramp rate (e.g., 5 °C/min) to eliminate the risk of cracking due to thermal shock.

- If your primary focus is Material Consistency: Standardize the cooling rate precisely to ensure the defect gradient is identical in every batch.

Control the temperature to control the material properties.

Summary Table:

| Factor | Recommended Rate | Primary Purpose | Impact of Failure |

|---|---|---|---|

| Heating Rate | ~5 °C / minute | Prevent thermal shock | Catastrophic crystal cracking |

| Structural Control | Gradual Ramping | Uniform lattice expansion | Internal stress and micro-fractures |

| Cooling Rate | Controlled Decline | Lock in defect gradient | Inconsistent material properties |

| Environment | Hydrogen Gas | Chemical reduction | Non-uniform chemical reduction |

Maximize Your Material Yield with KINTEK Precision

Don’t let thermal shock compromise your high-value lithium niobate crystals. KINTEK provides state-of-the-art Tube, Vacuum, and CVD systems designed for the rigorous demands of thermal reduction. Our furnaces offer industry-leading ramp-rate precision and atmosphere control, backed by expert R&D to ensure your results are consistent, reproducible, and crack-free.

Ready to elevate your lab's performance? Contact us today to discuss our customizable high-temp furnace solutions tailored for your unique research needs.

Visual Guide

References

- Yunjia Bao, Dongfeng Xue. Machine‐Learning‐Assisted Understanding of Depth‐Dependent Thermal Conductivity in Lithium Niobate Induced by Point Defects. DOI: 10.1002/aelm.202400944

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a laboratory tube furnace play in the annealing of low carbon steel? Precision Heat for Nanocomposites

- Why is a tube furnace with precise temperature control required for CuSbSe2 thin films? Achieve High Phase Purity

- What is the specific function of a high-temperature tube furnace for MXene-NiCo2Se4? Master the Selenization Process

- What is the purpose of pre-treating quartz tube reactors? Achieve High-Purity CVT Crystal Growth with Precision

- Why use stainless steel or nickel foil liners in tube furnaces? Protect Your Equipment During KOH Activation

- What conditions does a tube furnace provide for aluminum ash-based ceramsite roasting? Master Precision Sintering

- What is a vertical furnace? A Guide to High-Purity, Uniform Thermal Processing

- What is the purpose of introducing nitrogen flow into a tube furnace? Optimize Your Activated Carbon Calcination