In short, routine maintenance for a dental furnace is an operational necessity, not an optional task. It is the single most effective way to guarantee consistent sintering quality, prevent catastrophic and costly downtime, and significantly extend the functional lifespan of your equipment.

Neglecting furnace maintenance invites unpredictable results, sudden failures, and high replacement costs. A structured, proactive maintenance routine transforms your furnace from a potential liability into a reliable asset that consistently produces high-quality restorations.

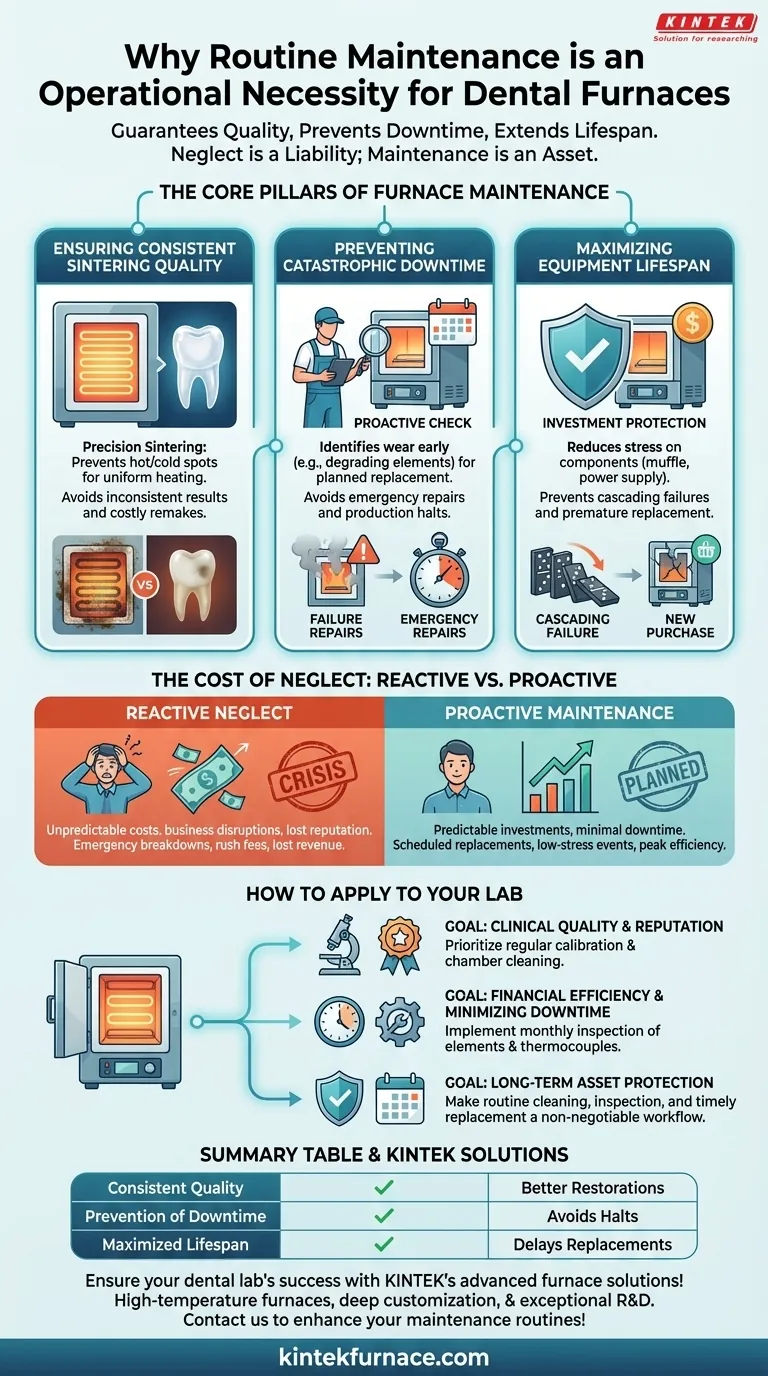

The Core Pillars of Furnace Maintenance

To understand its importance, we must look beyond the simple act of cleaning. Effective maintenance is about controlling the critical variables that dictate success in a dental lab: quality, uptime, and cost.

Ensuring Consistent Sintering Quality

The final aesthetic and structural integrity of a zirconia restoration are directly tied to the precision of the sintering cycle.

Dirty or corroded heating elements do not heat evenly. This creates hot and cold spots within the firing chamber, leading to inconsistent sintering, poor marginal fit, and compromised translucency or shade.

Regular cleaning of the chamber and elements removes contaminants that can otherwise deposit on the restoration surface, affecting the final outcome and requiring costly remakes.

Preventing Catastrophic Downtime

A furnace failure halts production. This is the most significant and immediate risk of poor maintenance.

Routine checks allow you to identify component wear and tear—such as degrading heating elements or aging thermocouples—before they fail completely. This allows for scheduled, proactive replacement instead of emergency repairs.

A simple visual inspection can spot a potential issue weeks before it would have shut down your lab's entire crown and bridge production line.

Maximizing Equipment Lifespan

A dental furnace is a major capital investment. Maintenance is the most cost-effective way to protect that investment.

Unchecked corrosion or element degradation places additional stress on other components, including the furnace muffle (firing chamber) and power supply.

This cascading effect can turn a minor, replaceable part's failure into a major system breakdown, prematurely ending the furnace's life and forcing a new purchase far sooner than necessary.

Understanding the True Cost of Neglect

The trade-off is not between "maintenance" and "no maintenance." It is between small, predictable investments of time and money versus large, unpredictable costs and business disruptions.

The Hidden Costs of Inconsistency

When a furnace performs unreliably, the costs go far beyond the unit itself. It leads to remakes, wasted material, lost technician time, and frustrated clients. This directly impacts your lab's profitability and, more importantly, its reputation.

Reactive vs. Proactive Repairs

A planned heating element replacement is a low-stress, scheduled event with minimal downtime. An emergency breakdown is a crisis that involves rush shipping fees, potential technician overtime, and days of lost revenue while you wait for parts.

Error Codes and Performance Drift

Modern furnaces generate error codes when performance deviates from its baseline. Proactive maintenance and calibration can detect and resolve these issues early, often through remote diagnostics, ensuring the furnace operates at peak efficiency throughout its life.

How to Apply This to Your Lab

Implementing a maintenance plan is about shifting from a reactive to a proactive mindset. The specific focus may change based on your lab's primary goals.

- If your primary focus is clinical quality and reputation: Prioritize regular calibration and chamber cleaning to guarantee consistent and accurate sintering temperatures.

- If your primary focus is financial efficiency and minimizing downtime: Implement a monthly schedule to inspect heating elements and thermocouples, replacing them based on usage or visible wear.

- If your primary focus is long-term asset protection: Treat routine cleaning, inspection, and timely component replacement as a non-negotiable part of your workflow to maximize the furnace's operational life.

Ultimately, a well-maintained furnace is the foundation of a predictable, profitable, and reputable dental laboratory.

Summary Table:

| Maintenance Benefit | Key Impact |

|---|---|

| Consistent Sintering Quality | Prevents hot/cold spots, ensures uniform heating for better zirconia restorations |

| Prevention of Downtime | Identifies wear early, avoids emergency repairs and production halts |

| Maximized Lifespan | Protects investment by reducing stress on components, delaying replacements |

Ensure your dental lab's success with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide dental laboratories with high-temperature furnaces like Muffle, Tube, and Vacuum & Atmosphere Furnaces, backed by strong deep customization to meet your unique needs. Contact us today to enhance your maintenance routines and achieve reliable, high-quality results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations