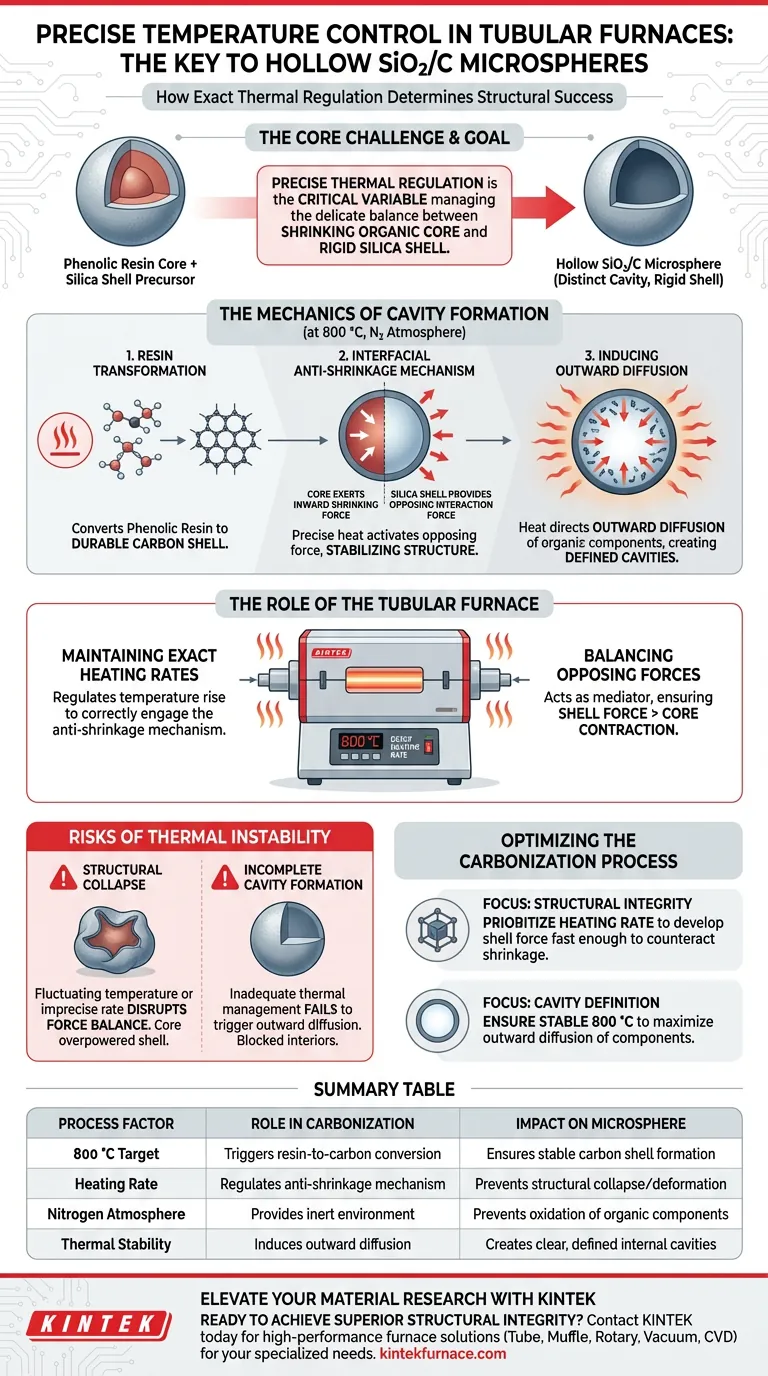

Precise thermal regulation is the critical variable determining the structural success of hollow SiO2/C microspheres. In a tubular furnace, exact temperature control during carbonization manages the delicate physical balance between the shrinking organic core and the rigid silica shell, ensuring the formation of distinct internal cavities rather than collapsed or solid structures.

Precise temperature control regulates the transformation of phenolic resin into carbon at 800 °C. By maintaining an exact heating rate, the furnace triggers an interfacial anti-shrinkage mechanism where the outer silica shell effectively counteracts the core's inward shrinking force, creating a stable hollow architecture.

The Mechanics of Cavity Formation

Governing Resin Transformation

The primary objective of the carbonization process is to convert the phenolic resin precursor into a durable carbon shell.

This transformation requires a stable environment, specifically maintained at 800 °C under a nitrogen atmosphere.

The Interfacial Anti-Shrinkage Mechanism

The most critical phenomenon occurring during this process is the interfacial anti-shrinkage mechanism.

As the organic core heats up, it naturally exerts an inward shrinking force.

However, precise heat application activates an opposing interaction force from the outer silica shell, which stabilizes the structure against this collapse.

Inducing Outward Diffusion

Proper thermal management does more than just harden the shell; it directs the movement of material.

The heat induces the outward diffusion of organic components.

This migration of material from the center to the periphery is what ultimately results in the formation of clear, defined internal cavities.

The Role of the Tubular Furnace

Maintaining Exact Heating Rates

The tubular furnace is essential because it allows for the strict regulation of the heating rate.

It is not enough to simply reach 800 °C; the rate at which the temperature rises determines if the anti-shrinkage mechanism engages correctly.

Balancing Opposing Forces

The furnace acts as the mediator between two competing physical forces.

It ensures the interfacial interaction force provided by the silica shell remains strong enough to counteract the core's contraction.

Without this balance, the mechanics of the microsphere would fail, compromising the hollow design.

Risks of Thermal Instability

Structural Collapse

If the temperature control fluctuates or the heating rate is imprecise, the delicate force balance is disrupted.

If the inward shrinking force of the organic core overpowers the outer shell's resistance, the microsphere may collapse or deform.

Incomplete Cavity Formation

Inadequate thermal management can fail to trigger the necessary outward diffusion of organic components.

This results in microspheres with blocked or partially filled interiors, rather than the desired hollow SiO2/C structure.

Optimizing the Carbonization Process

To achieve high-quality hollow microspheres, you must treat temperature as a dynamic tool rather than a static setting.

- If your primary focus is Structural Integrity: Prioritize the heating rate to ensure the silica shell's interaction force develops fast enough to counteract core shrinkage.

- If your primary focus is Cavity Definition: Ensure the furnace holds a stable 800 °C to maximize the outward diffusion of organic components.

Mastering the thermal environment is the only way to turn the theoretical mechanics of anti-shrinkage into a physical reality.

Summary Table:

| Process Factor | Role in Carbonization | Impact on Microsphere |

|---|---|---|

| 800 °C Target | Triggers phenolic resin to carbon conversion | Ensures stable carbon shell formation |

| Heating Rate | Regulates interfacial anti-shrinkage mechanism | Prevents structural collapse/deformation |

| Nitrogen Atmosphere | Provides inert environment for carbonization | Prevents oxidation of organic components |

| Thermal Stability | Induces outward diffusion of components | Creates clear, defined internal cavities |

Elevate Your Material Research with KINTEK

Precision is the difference between structural success and failure in advanced carbonization. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems designed to provide the exact thermal regulation required for your unique lab applications. Whether you are developing hollow SiO2/C microspheres or advanced composites, our customizable high-temp furnaces ensure perfect heating rates and atmospheric control every time.

Ready to achieve superior structural integrity? Contact KINTEK today to find the ideal furnace solution for your specialized research needs!

Visual Guide

References

- Lixue Gai, Yunchen Du. Compositional and Hollow Engineering of Silicon Carbide/Carbon Microspheres as High-Performance Microwave Absorbing Materials with Good Environmental Tolerance. DOI: 10.1007/s40820-024-01369-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why is it important to calibrate the temperature profile of a tube furnace? Ensure Accurate and Repeatable Results

- What are common uses of tube furnaces? Precision Heating for Material Synthesis and Control

- What are the primary functions of a tube furnace in the thermal pre-treatment research of aluminum alloy powder?

- What are some common applications of tubular furnaces? Unlock Precision in High-Temperature Processing

- What is the recommended procedure for using a tube furnace after long periods of inactivity? Prevent Damage with Proper Bake-Out

- What are the technical specifications of the two-heating-zone tube furnace? Unlock Precise Thermal Gradients

- What role does a high-temperature tube furnace play in transforming photopolymerized parts into fully aromatic polyimide?

- How does a high-temperature tube furnace ensure environmental stability for SOEC? Precision Heat & Atmosphere Control