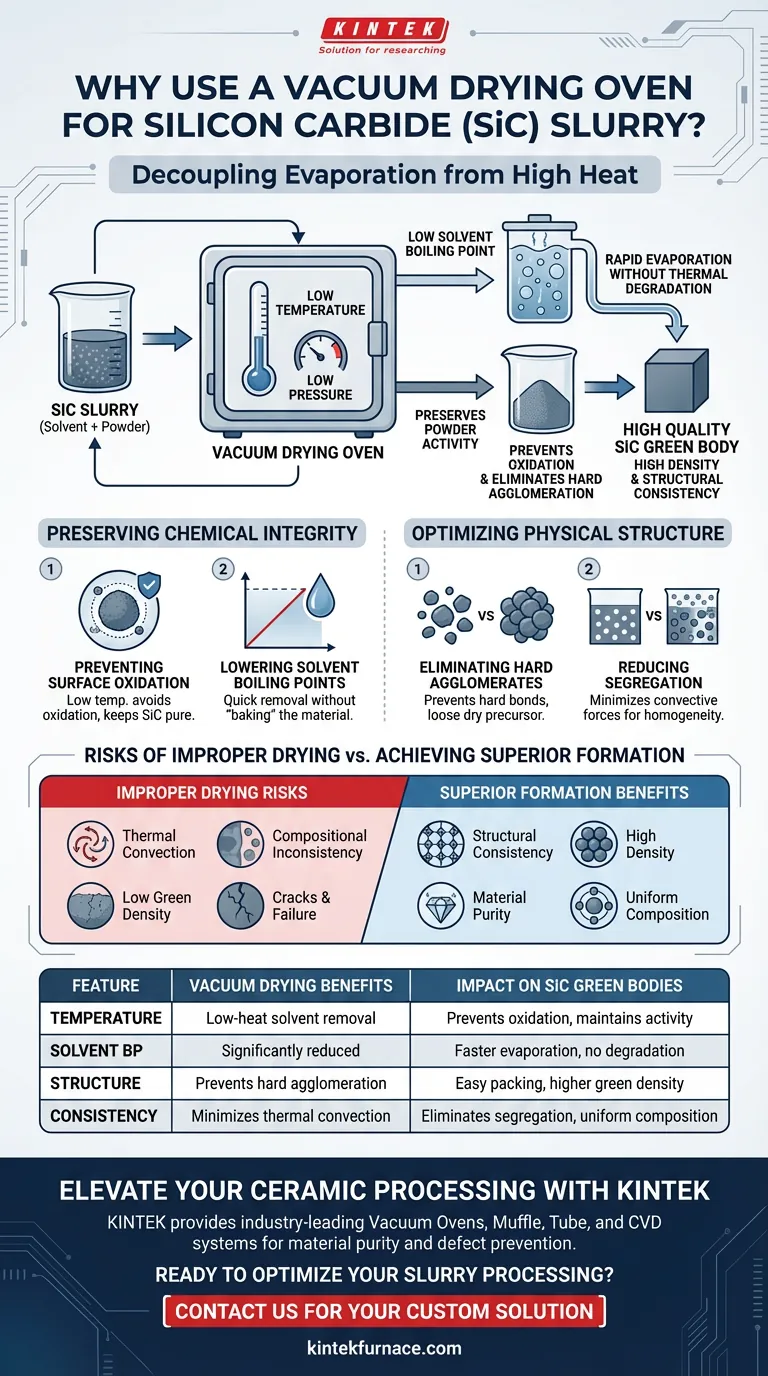

The necessity of using a vacuum drying oven for Silicon Carbide (SiC) slurry lies in its ability to decouple evaporation from high heat. By operating in a low-pressure environment, the oven significantly lowers the boiling point of solvents like anhydrous ethanol, allowing them to be removed rapidly without subjecting the powder to damaging temperatures.

The core value of vacuum drying is the preservation of powder activity and homogeneity. It eliminates the risks of oxidation and hard agglomeration, ensuring the subsequent green bodies achieve high density and structural consistency.

Preserving Chemical Integrity

Preventing Surface Oxidation

Silicon Carbide is sensitive to high temperatures, particularly in the presence of air. Standard drying methods often require heat levels that induce surface oxidation on the powder particles.

Vacuum drying operates at much lower temperatures. This low-thermal approach keeps the chemical composition of the SiC powder pure and maintains its initial surface activity.

Lowering Solvent Boiling Points

In a vacuum, the pressure is reduced significantly. This physical change drops the boiling point of solvents contained in the slurry.

Consequently, solvents can be removed quickly and completely without "baking" the material. This is critical for efficient processing without thermal degradation.

Optimizing Physical Structure

Eliminating Hard Agglomerates

Prolonged heating in standard ovens often causes particles to bind together, forming hard agglomerates. These clumps create defects and weak points in the final ceramic product.

Vacuum drying is rapid and occurs at low temperatures, preventing these hard bonds from forming. The result is a loose, dry precursor powder that is easy to process.

Reducing Segregation

Standard drying can induce intense thermal convection—hot air currents that move particles around. This often leads to segregation, where different components of the slurry separate, causing uneven composition.

Vacuum drying minimizes these convective forces. This ensures the mixture remains homogeneous throughout the drying phase.

Understanding the Risks of Improper Drying

The Cost of Thermal Convection

If you rely on high-temperature air drying, you risk compositional inconsistency. The physical movement of solvents and particles caused by heat currents destroys the uniformity of your slurry mix.

Impact on Green Density

Using powder that has suffered oxidation or agglomeration leads to poor packing during the pressing stage. This results in low green density and inconsistent structural integrity in the molded body, leading to cracks or failure during sintering.

Achieving Superior Green Body Formation

If your primary focus is Structural Consistency:

- Prioritize vacuum drying to prevent component segregation and ensure the material composition is uniform throughout the green body.

If your primary focus is High Density:

- Use vacuum drying to eliminate hard agglomerates, ensuring the powder remains loose and packs tightly during the molding process.

If your primary focus is Material Purity:

- Rely on the low-temperature capabilities of vacuum processing to prevent surface oxidation and maintain the original activity of the SiC powder.

Vacuum drying is not just a drying step; it is a quality control measure that guarantees the physical and chemical foundation of your final ceramic product.

Summary Table:

| Feature | Vacuum Drying Benefits | Impact on SiC Green Bodies |

|---|---|---|

| Temperature | Low-heat solvent removal | Prevents surface oxidation and maintains powder activity |

| Solvent Boiling Point | Significantly reduced | Faster evaporation without thermal degradation |

| Particle Structure | Prevents hard agglomeration | Ensures easy packing and higher green density |

| Consistency | Minimizes thermal convection | Eliminates component segregation for uniform composition |

Elevate Your Ceramic Processing with KINTEK

Precision in the drying stage is critical for the structural integrity of Silicon Carbide components. KINTEK provides industry-leading thermal solutions, including high-performance Vacuum Ovens, Muffle, Tube, and CVD systems, specifically engineered to preserve material purity and prevent defects.

Backed by expert R&D and world-class manufacturing, our systems are fully customizable to meet your unique laboratory or production requirements. Don't let oxidation or agglomeration compromise your results—partner with KINTEK for superior homogeneity and density.

Ready to optimize your slurry processing? Contact us today to find your custom solution.

Visual Guide

References

- Jie Long, Орест Кочан. Preparation of Oily Sludge-Derived Activated Carbon and Its Adsorption Performance for Tetracycline Hydrochloride. DOI: 10.3390/molecules29040769

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What advancements have been made in vacuum furnace energy efficiency and environmental impact? Discover Cleaner, More Efficient Heat Treatment

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What methods are used for cooling parts after vacuum furnace heat treatment? Optimize Your Metal Properties

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What was the traditional insulation setup in vacuum furnaces, and how has it changed? Discover the Modern All-Felt System

- Why is high-temperature treatment in a vacuum annealing furnace required after the assembly of multilayer heterostructures?

- Why are vanadium windows used in vacuum furnaces for neutron scattering? Achieve Peak Signal Integrity for SDSS2507

- What is the necessity of using a vacuum chamber before curing epoxy? Eliminate Defects for Superior Material Integrity