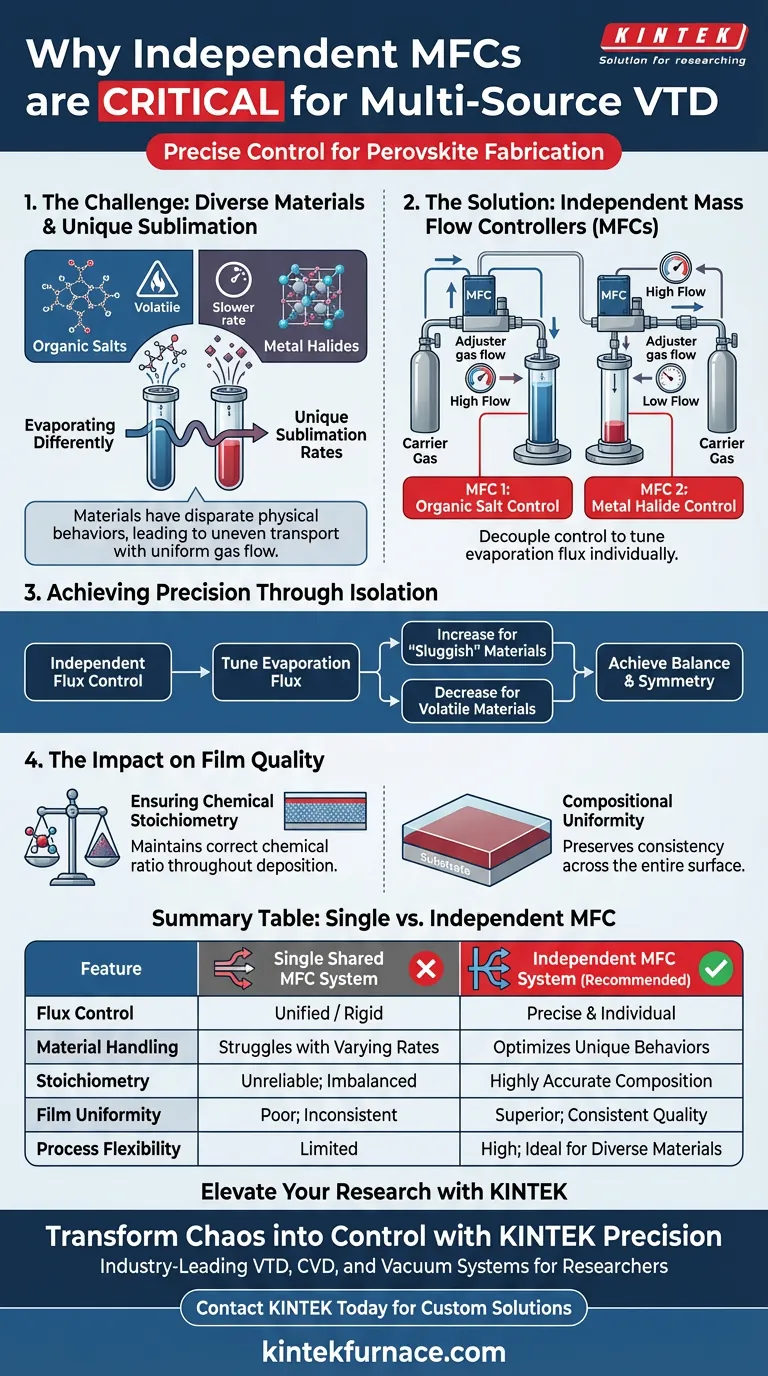

The necessity of independent Mass Flow Controllers (MFCs) in multi-source VTD devices is driven by the disparate physical behaviors of the materials involved in perovskite fabrication. Because the process relies on multiple precursors—specifically organic salts and metal halides—that possess unique sublimation properties, a uniform gas flow across all sources would result in uneven transport. Independent MFCs allow you to regulate the carrier gas flow for each source tube individually, granting you precise control over the evaporation flux of each distinct component.

Perovskite precursors evaporate at different rates due to unique physical properties. Independent MFCs enable precise control over the carrier gas for each specific component, ensuring the correct chemical stoichiometry and uniformity in the final thin film.

Managing Diverse Material Properties

The Challenge of Multiple Precursors

Perovskite materials are not singular compounds during the deposition phase; they are formed from a mixture of precursors.

Commonly, this involves combining organic salts with metal halides.

Unique Sublimation Rates

Each of these precursors possesses a unique sublimation property.

Consequently, they do not transition from solid to vapor at the same rate under identical conditions.

The Role of Carrier Gas

The carrier gas is responsible for transporting the vaporized material to the substrate.

If the gas flow is identical for all sources, materials with faster sublimation rates will be over-represented in the vapor stream.

Achieving Precision Through Isolation

Independent Flux Control

By installing an independent MFC for each source tube, you effectively decouple the control of one material from another.

This allows you to adjust the transport speed of the metal halide without inadvertently altering the transport of the organic salt.

Tuning Evaporation Flux

This hardware configuration enables the specific tuning of evaporation flux for each component.

Operators can increase flow for "sluggish" materials and decrease it for highly volatile ones to achieve balance.

Understanding the Trade-offs

Complexity vs. Control

Implementing independent MFCs increases the complexity and calibration requirements of the VTD system.

However, this complexity is the necessary cost of handling materials with such divergent physical characteristics.

The Consequence of Unified Flow

Attempting to run a multi-source VTD system with a single shared flow controller is a common pitfall.

This inevitably leads to an inability to compensate for natural variations in precursor behavior, resulting in failed depositions.

The Impact on Film Quality

Ensuring Chemical Stoichiometry

The ultimate goal of VTD is to create a film with a specific chemical composition.

Independent fluid control is the only reliable method to ensure the correct stoichiometry is maintained throughout the deposition process.

Compositional Uniformity

Beyond just the ratio of ingredients, the film must be consistent across its entire surface.

Precise, independent flow control ensures that the compositional uniformity of the final perovskite thin film is preserved.

Making the Right Choice for Your Goal

To maximize the effectiveness of a multi-source VTD system, you must leverage independent flow control to stabilize the inherent volatility of the process.

- If your primary focus is Chemical Purity: Calibrate each MFC individually to match the specific sublimation rate of its assigned precursor, ensuring exact stoichiometry.

- If your primary focus is Film Uniformity: Use the independent controls to fine-tune the evaporation flux, preventing concentration gradients across the substrate.

Independent MFCs transform a chaotic mix of evaporation rates into a synchronized, controllable deposition process.

Summary Table:

| Feature | Single shared MFC System | Independent MFC System (Recommended) |

|---|---|---|

| Flux Control | Unified/Rigid | Precise & Individual per precursor |

| Material Handling | Struggles with varying sublimation rates | Optimizes unique sublimation behaviors |

| Stoichiometry | Unreliable; prone to imbalance | Highly accurate chemical composition |

| Film Uniformity | Poor; inconsistent across surface | Superior; consistent thickness and quality |

| Process Flexibility | Limited to similar materials | High; ideal for organic salts & metal halides |

Elevate Your Thin Film Deposition with KINTEK Precision

Achieving perfect perovskite stoichiometry requires hardware that can handle complex material behaviors. KINTEK provides industry-leading Vapor Transport Deposition (VTD), CVD, and Vacuum systems designed specifically for researchers who demand precision.

Backed by our expert R&D and manufacturing, our systems feature customizable gas flow configurations and independent control modules tailored to your unique lab needs. Don't let uneven sublimation rates compromise your research—partner with KINTEK to ensure absolute compositional uniformity and high-purity results.

Ready to optimize your deposition process? Contact KINTEK today for a custom solution!

Visual Guide

References

- Dachang Liu. Vapor Transport Deposition Technology for Perovskite Films. DOI: 10.1002/admi.202500064

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is the purpose of using an industrial oven for the pretreatment of reinforcement powders? | Enhance Composite Bond

- Why is an excess of lithium carbonate added for LiScO2:Cr3+? Optimize Your High-Temp Phosphor Synthesis

- What is the role of mortar grinding combined with heat gun processing in catalyst synthesis? Achieving PtCln Dispersion

- What is the function of an inert gas supply system in black liquor pyrolysis? Achieve Precise Atmospheric Control

- Why Roast SiC Particles for 2024Al/Gr/SiC Composites? Optimize Surface Modification and Bonding

- How does a sputtering system contribute to the preparation of electrodes? Enhance Bismuth Telluride Characterization

- What is the function of solution and aging heat treatment furnaces? Optimize 17-4 PH Stainless Steel Properties

- What are the key characteristics of furnaces used in 3D printing sintering? Achieve Precision Sintering for High-Quality Parts