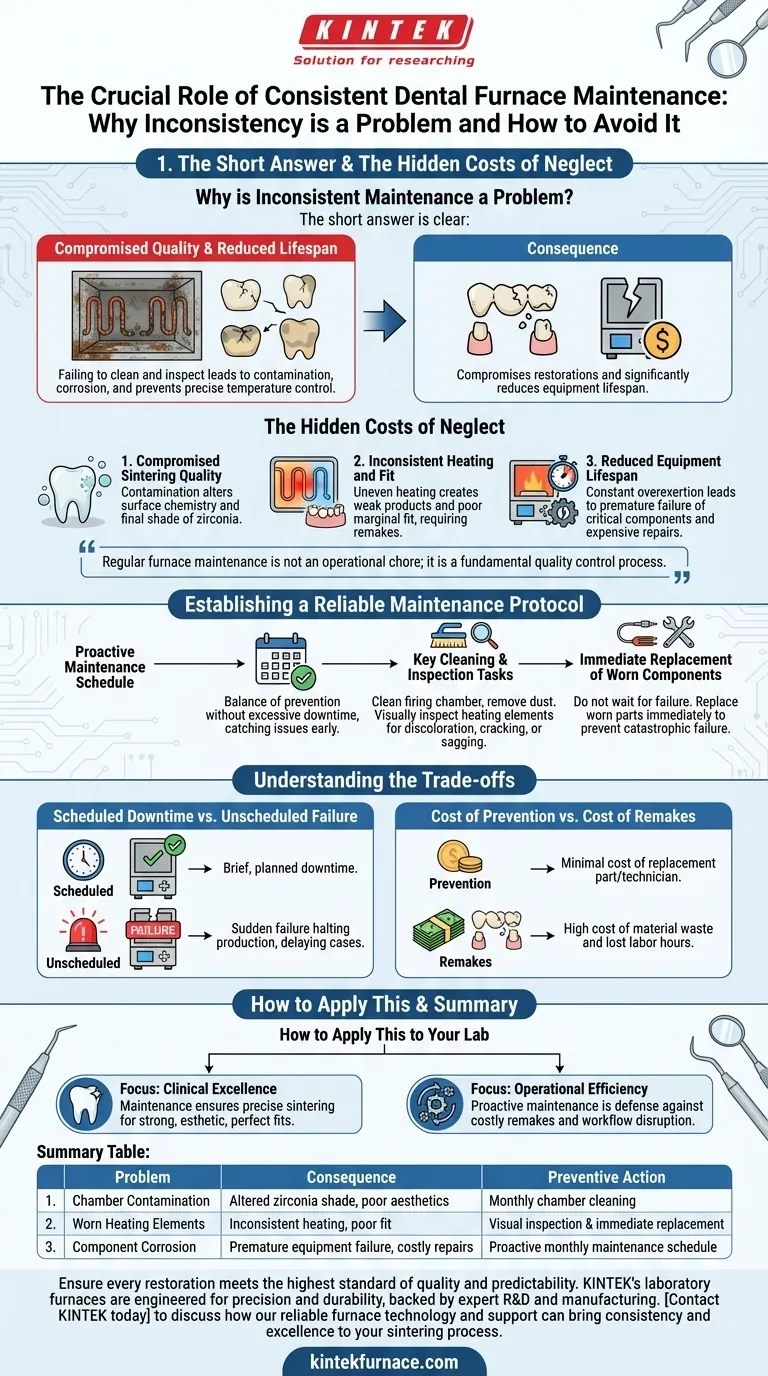

The short answer is clear: Inconsistent maintenance of a dental furnace directly compromises the quality of your restorations and significantly reduces the lifespan of your equipment. Failing to regularly clean furnace chambers and inspect heating elements leads to contamination and corrosion, which prevents the precise temperature control required for successful sintering.

Regular furnace maintenance is not an operational chore; it is a fundamental quality control process. It directly protects the integrity of your final product, prevents costly equipment failure, and ensures predictable results for every case.

The Hidden Costs of Neglect

Ignoring furnace upkeep introduces variables that undermine the precision your work demands. The consequences extend beyond the equipment itself, impacting workflow, material costs, and your lab's reputation.

Compromised Sintering Quality

A clean furnace provides a controlled, neutral atmosphere. Contamination from debris or corroded elements can release gases during the heating cycle, altering the surface chemistry and final shade of the zirconia or other ceramic materials. This leads to restorations that do not meet quality standards.

Inconsistent Heating and Fit

Dirty or aging heating elements do not heat evenly. This creates hot and cold spots within the chamber, resulting in incomplete or inconsistent sintering across the restoration. The consequence is a weakened final product with potential for poor marginal fit, requiring time-consuming adjustments or a complete remake.

Reduced Equipment Lifespan

Corrosion and contamination force heating elements to work harder to reach and maintain target temperatures. This constant overexertion leads to premature failure of the elements and other critical components, turning a predictable maintenance task into an expensive, unscheduled repair.

Establishing a Reliable Maintenance Protocol

The solution is to move from reactive repairs to a proactive maintenance schedule. A simple, repeatable checklist is the most effective way to ensure consistency and protect your investment.

The Monthly Maintenance Check

For most dental labs, a monthly check provides the right balance of prevention without excessive downtime. This schedule ensures that potential issues are caught long before they can impact a patient case.

Key Cleaning and Inspection Tasks

Your routine check should always include cleaning the furnace's firing chamber and inspecting the heating elements. Gently remove any dust or debris from the chamber floor. Visually inspect elements for any signs of discoloration, cracking, or sagging, as these are indicators of wear.

Immediate Replacement of Worn Components

Do not wait for a component to fail completely. If an element or thermocouple shows visible signs of wear and tear, it should be replaced immediately. Postponing replacement risks a catastrophic failure during a firing cycle, which can ruin an entire batch of restorations.

Understanding the Trade-offs

Implementing a maintenance program requires a small investment of time, but it pays significant dividends by preventing much larger problems.

Scheduled Downtime vs. Unscheduled Failure

Performing monthly maintenance requires a brief, scheduled period where the furnace is offline. This controlled downtime is vastly preferable to a sudden, unexpected equipment failure that can halt production, delay cases, and damage your lab's relationship with its clients.

The Cost of Prevention vs. The Cost of Remakes

The cost of a replacement heating element or a technician's time for maintenance is minimal compared to the cost of remaking a multi-unit zirconia bridge. Proactive maintenance is a direct investment in reducing material waste and lost labor hours associated with failed cases.

How to Apply This to Your Lab

A consistent approach to furnace maintenance is essential for any modern dental laboratory. Your specific focus will determine how you frame its importance.

- If your primary focus is clinical excellence: Consistent maintenance is the only way to eliminate equipment variables and guarantee the precise sintering needed for strong, esthetic, and perfectly fitting restorations.

- If your primary focus is operational efficiency: A proactive monthly maintenance schedule is your best defense against costly remakes, wasted materials, and unexpected equipment failures that disrupt workflow.

Ultimately, taking control of your equipment maintenance gives you direct control over the quality and predictability of your lab's output.

Summary Table:

| Problem from Inconsistent Maintenance | Consequence | Preventive Action |

|---|---|---|

| Chamber Contamination | Altered zirconia shade, poor aesthetics | Monthly chamber cleaning |

| Worn Heating Elements | Inconsistent heating, poor fit | Visual inspection & immediate replacement |

| Component Corrosion | Premature equipment failure, costly repairs | Proactive monthly maintenance schedule |

Ensure every restoration meets the highest standard of quality and predictability.

Inconsistent furnace maintenance introduces variables that compromise your final product and disrupt your workflow. Protect your investment and your reputation with a reliable maintenance protocol.

KINTEK's laboratory furnaces are engineered for precision and durability, backed by expert R&D and manufacturing. Whether you require a standard model or a fully customized solution for your unique dental lab needs, our team is here to support you.

Contact KINTEK today to discuss how our reliable furnace technology and support can bring consistency and excellence to your sintering process.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations