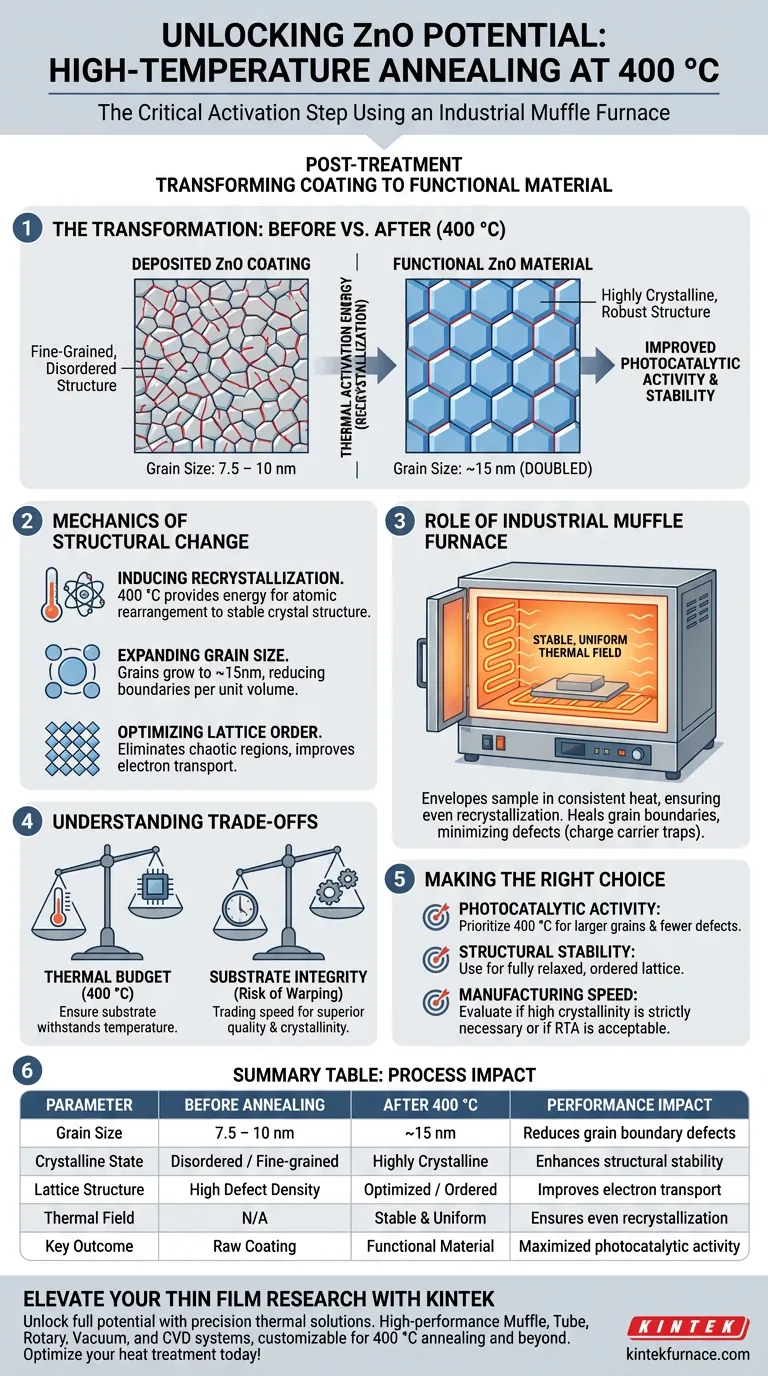

High-temperature annealing at 400 °C is the critical activation step for Zinc Oxide (ZnO) thin films, serving as the bridge between deposition and functional performance. This process utilizes the stable thermal environment of an industrial muffle furnace to drive recrystallization, effectively doubling the grain size from roughly 7.5–10 nm to 15 nm. By repairing lattice defects and enhancing structural order, this treatment directly unlocks the material's photocatalytic potential and long-term stability.

The core objective of this process is to transition the ZnO material from a disordered, fine-grained state into a robust, highly crystalline structure. By providing the thermal energy required for atomic rearrangement, you significantly reduce grain boundary defects, which is the primary driver for improved photocatalytic activity.

The Mechanics of Structural Transformation

Inducing Recrystallization

The 400 °C setpoint is not arbitrary; it provides the specific thermal activation energy required to initiate recrystallization in the Zinc Oxide film.

At lower temperatures, the atoms within the film lack the mobility to correct structural irregularities. The high-temperature environment allows these atoms to migrate and rearrange themselves into a more thermodynamically stable crystal structure.

Expanding Grain Size

A defining metric of this process is the tangible increase in grain size.

Before annealing, the ZnO grains typically measure between 7.5 nm and 10 nm. After treatment in the muffle furnace, these grains grow to approximately 15 nm. This growth is crucial because larger grains result in fewer boundaries per unit volume.

Optimizing Lattice Order

As grains grow and the crystal structure stabilizes, the internal arrangement of the lattice becomes more uniform.

This optimization eliminates atomic-level chaotic regions. A highly ordered lattice allows for better electron transport, which is fundamental to the material's performance in electronic and photonic applications.

The Role of the Industrial Muffle Furnace

Ensuring a Stable Thermal Field

The choice of an industrial muffle furnace is dictated by the need for a stable thermal field.

Unlike rapid thermal processing which focuses on speed, a muffle furnace envelopes the sample in a consistent, uniform heat. This uniformity is essential for ensuring that the recrystallization occurs evenly across the entire surface of the thin film, preventing localized structural weak points.

Reducing Grain Boundary Defects

The combination of sufficient heat and thermal stability targets grain boundary defects.

Grain boundaries often act as "traps" for charge carriers, reducing the efficiency of the material. By growing the grains and healing these boundaries, the muffle furnace annealing process minimizes these defects, directly enhancing the material's photocatalytic activity.

Understanding the Trade-offs

Thermal Budget vs. Substrate Integrity

While 400 °C is optimal for ZnO recrystallization, it represents a significant thermal budget.

You must ensure your substrate can withstand this temperature without warping or degrading. If the substrate is temperature-sensitive (like certain polymers), this specific annealing process cannot be used without compromising the mechanical integrity of the device.

Process Time vs. Throughput

Muffle furnace annealing is typically a slower process compared to rapid thermal annealing (RTA).

While it provides superior uniformity and stability for this specific phase transformation, it creates a bottleneck in manufacturing throughput. You are trading processing speed for higher structural quality and crystallinity.

Making the Right Choice for Your Goal

This annealing process is a tool, not a universal rule. Apply it based on your specific performance requirements.

- If your primary focus is Photocatalytic Activity: Prioritize this 400 °C treatment to maximize grain size and minimize the defect sites that trap charge carriers.

- If your primary focus is Structural Stability: Use this process to ensure the lattice is fully relaxed and ordered, preventing degradation over time.

- If your primary focus is Manufacturing Speed: Evaluate if the high crystallinity provided by the muffle furnace is strictly necessary, or if a faster, lower-quality method (like RTA) is acceptable for your tolerance levels.

The 400 °C annealing step is the difference between a deposited coating and a high-performance functional material.

Summary Table:

| Process Parameter | Before Annealing | After 400 °C Annealing | Impact on Performance |

|---|---|---|---|

| Grain Size | 7.5 nm – 10 nm | ~15 nm | Reduces grain boundary defects |

| Crystalline State | Disordered/Fine-grained | Highly Crystalline | Enhances structural stability |

| Lattice Structure | High Defect Density | Optimized/Ordered | Improves electron transport |

| Thermal Field | N/A | Stable & Uniform | Ensures even recrystallization |

| Key Outcome | Raw Coating | Functional Material | Maximized photocatalytic activity |

Elevate Your Thin Film Research with Precision Thermal Solutions

Unlock the full potential of your materials with KINTEK’s advanced thermal technology. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of 400 °C annealing and beyond.

Whether you need to double grain size or ensure a perfectly uniform lattice structure, our furnaces are fully customizable to fit your unique laboratory or industrial needs. Partner with KINTEK to achieve superior structural order and long-term stability in your thin film applications.

Ready to optimize your heat treatment process? Contact us today to consult with our experts!

Visual Guide

References

- Radka Gegova-Dzhurkova, I. Miloushev. Enhanced Photocatalytic Performance under Ultraviolet and Visible Light Illumination of ZnO Thin Films Prepared by Modified Sol-Gel Method. DOI: 10.3390/molecules29174005

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does a laboratory muffle furnace contribute to the multi-stage thermal treatment of mesoporous cobalt oxide (Co3O4)?

- What is the primary function of a high-temperature muffle furnace in LFP regeneration? Restore Battery Life with Precision

- What are the advantages of repeated calcination-reconstruction cycles for CuO nanoparticles? Master Precision Control

- How does a high-precision resistance furnace ensure T6 solution treatment? Achieve Peak Alloy Strength with KINTEK

- What maintenance practices extend a muffle furnace's lifespan? Boost Reliability with Proactive Care

- In which industries are muffle furnaces commonly used? Essential for Clean High-Temp Processing

- What is the temperature of a muffle oven? A Guide to Choosing the Right Range for Your Lab

- What are the proper procedures after completing an experiment with the muffle furnace? Ensure Safety and Data Accuracy