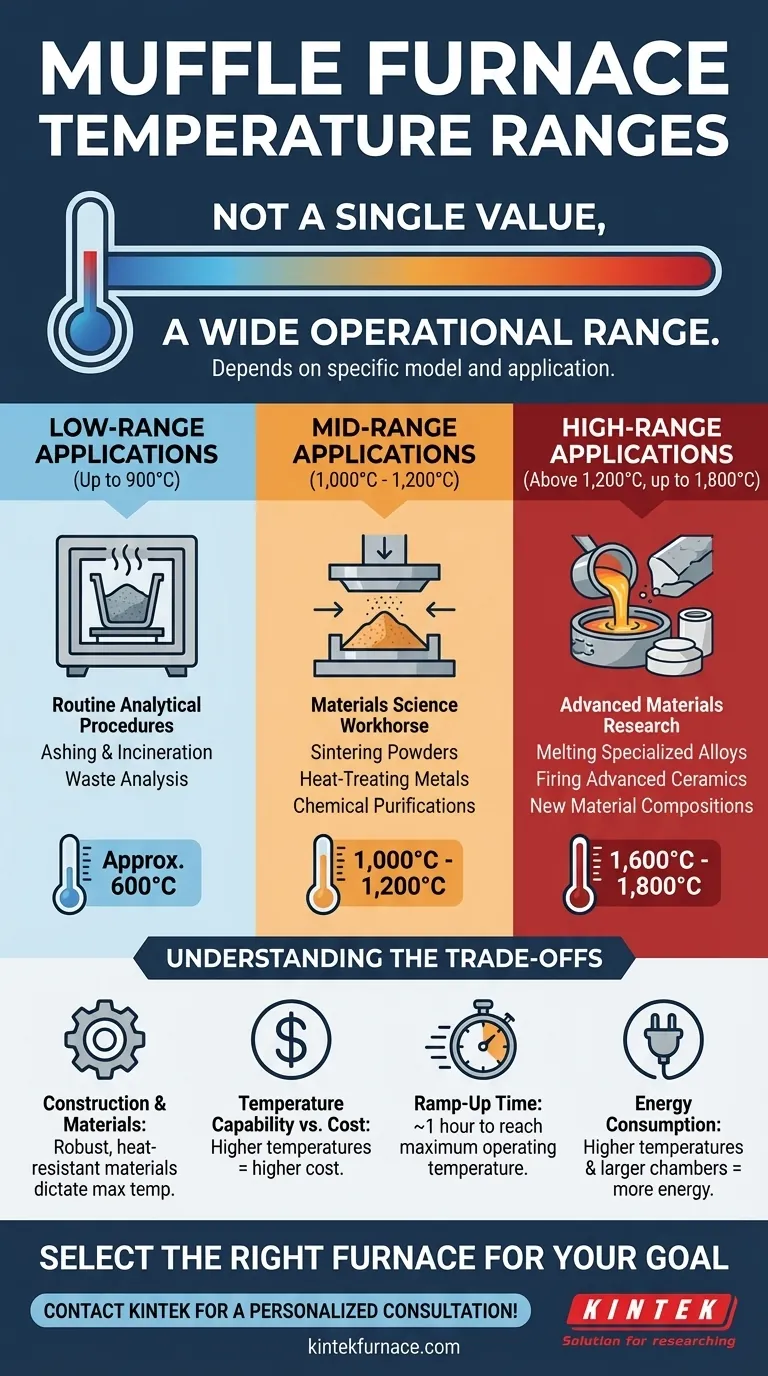

The temperature of a muffle furnace is not a single value, but rather a wide operational range that depends entirely on the specific model and its intended application. While some basic units operate around 600°C (1,112°F), standard models typically reach 1,200°C (2,192°F), and specialized high-temperature furnaces can achieve up to 1,800°C (3,272°F) or more.

A muffle furnace's temperature is a function of its design. The core question is not "what is the temperature," but "what temperature does my specific process require," as this will determine the type of furnace you need.

Why Muffle Furnace Temperatures Vary

A muffle furnace is fundamentally a high-temperature electric oven. Its capabilities are defined by its construction and its purpose. Understanding these factors is key to understanding its temperature range.

The Role of Construction and Materials

A furnace’s maximum temperature is dictated by the materials used in its heating chamber and insulation. The "muffle" itself is a protective shell, often made of ceramic, that isolates the sample from the direct radiation of the heating elements.

This design ensures uniform heating but requires robust, heat-resistant materials like firebrick and advanced ceramics to withstand the extreme internal environment. More expensive, higher-grade materials allow for higher maximum temperatures.

Standard vs. High-Temperature Models

The furnace market is generally divided into two tiers, which explains the broad temperature range you see cited.

Standard furnaces are the most common type found in general laboratories. They typically operate in the 1,000°C to 1,200°C range, making them suitable for a wide variety of common applications.

High-temperature furnaces are specialized pieces of equipment designed for advanced materials science and industrial processes. These models can reliably reach 1,600°C to 1,800°C to work with high-melting-point materials.

Matching Temperature to Application

The required temperature is directly tied to the scientific or industrial process being performed.

Lower-Range Applications (Up to 900°C)

Many routine analytical procedures do not require extreme heat. For example, ashing or incinerating organic samples, such as in wastewater analysis, is often performed at temperatures around 600°C.

Mid-Range Applications (1,000°C - 1,200°C)

This is the workhorse range for many materials science labs. Processes like sintering powders into a solid mass, heat-treating metals to alter their properties, and conducting various chemical purifications fall within this bracket.

High-Range Applications (Above 1,200°C)

Working with advanced materials demands the highest temperatures. This includes melting or testing specialized alloys, firing advanced ceramics, and researching new material compositions that require processing temperatures from 1,600°C to 1,800°C.

Understanding the Trade-offs

Choosing a muffle furnace involves balancing performance needs with practical constraints.

Temperature Capability vs. Cost

The relationship is direct: higher maximum temperatures require more advanced (and expensive) insulation, heating elements, and control systems. A furnace capable of 1,800°C can cost multiples of what a standard 1,200°C model does.

Ramp-Up Time

Reaching these extreme temperatures is not instantaneous. On average, a muffle furnace may require about one hour to reach its maximum operating temperature. This "ramp-up" time must be factored into any experimental or production schedule.

Energy Consumption

Maintaining temperatures above 1,000°C requires a significant and continuous supply of electrical power. Higher temperatures and larger chamber sizes will lead to substantially greater energy consumption and operational costs.

Making the Right Choice for Your Goal

Select a furnace based on the maximum temperature your most demanding process requires, with a small buffer for safety and flexibility.

- If your primary focus is routine analysis like ashing or solids testing: A basic furnace with a maximum temperature of 1,000°C to 1,100°C is sufficient and cost-effective.

- If your primary focus is general materials heat treatment or sintering: A standard 1,200°C furnace provides the versatility needed for most common lab applications.

- If your primary focus is advanced materials research or high-temp alloy testing: You must invest in a specialized high-temperature model capable of reaching 1,600°C to 1,800°C.

Ultimately, defining your specific application is the only way to determine the correct muffle furnace temperature for your needs.

Summary Table:

| Application Type | Typical Temperature Range | Common Uses |

|---|---|---|

| Low-Range | Up to 900°C | Ashing, Incineration, Waste Analysis |

| Mid-Range | 1,000°C - 1,200°C | Sintering, Heat Treatment, Purification |

| High-Range | Above 1,200°C (up to 1,800°C) | Advanced Alloys, Ceramics, Materials Research |

Ready to Find Your Perfect Muffle Furnace?

Your experimental success depends on precise temperature control. KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique requirements.

Our diverse product line, including Muffle Furnaces, Tube Furnaces, and specialized high-temperature models, is backed by deep customization capabilities. Whether you need a standard 1,200°C workhorse or a 1,800°C research-grade furnace, we can deliver a solution that fits your process and budget.

Let our experts help you select the ideal furnace for your application.

Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?