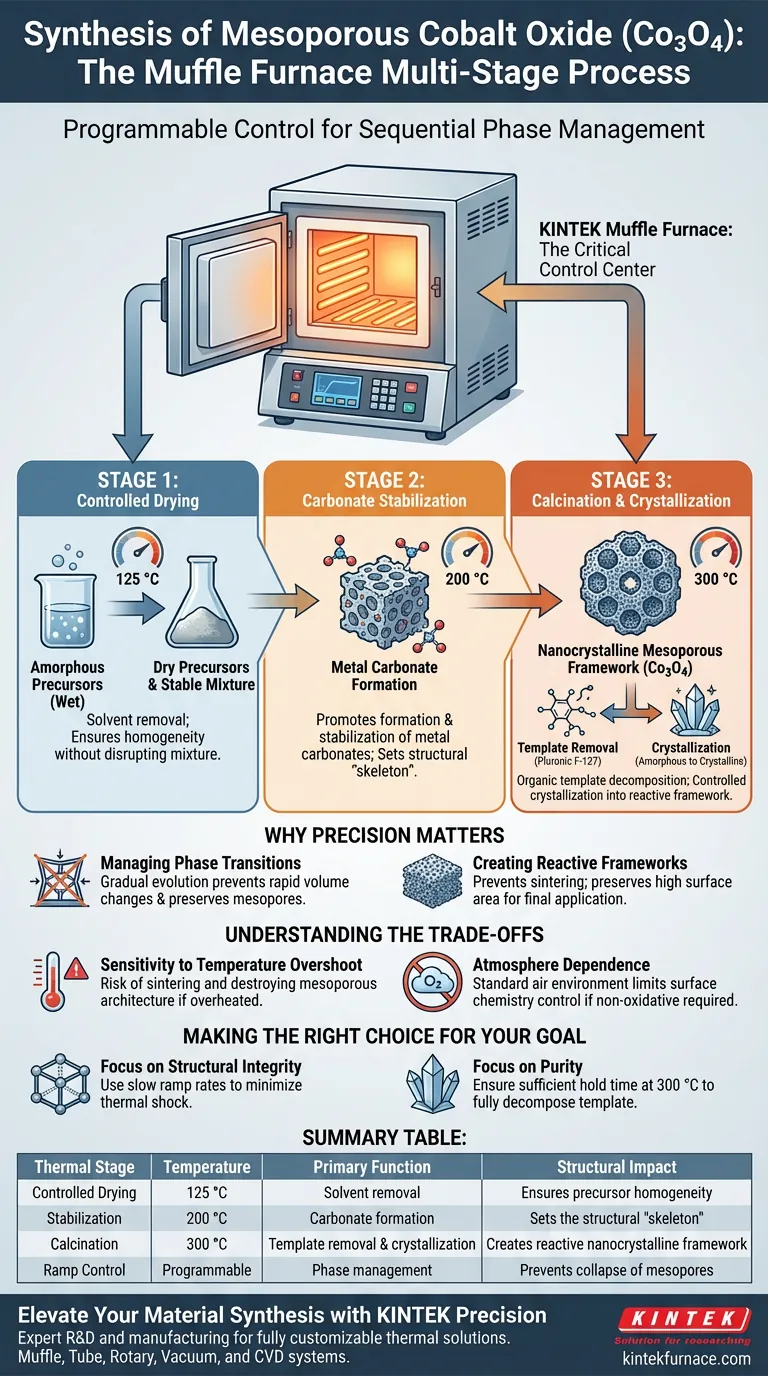

A laboratory muffle furnace serves as the critical, programmable control center for the synthesis of mesoporous cobalt oxide (Co3O4). It enables a specific multi-stage thermal protocol—drying at 125 °C, stabilizing at 200 °C, and calcining at 300 °C—to convert amorphous precursors into a highly reactive nanocrystalline framework.

Core Takeaway The muffle furnace is not merely a heat source; it is a tool for sequential phase management. Its ability to execute distinct temperature plateaus allows for the precise removal of organic templates and the controlled crystallization of Co3O4, ensuring the mesoporous structure is preserved rather than collapsed.

The Mechanics of Multi-Stage Processing

The synthesis of mesoporous Co3O4 relies on a delicate balance between removing material and building structure. The muffle furnace facilitates this through three distinct thermal stages.

Stage 1: Controlled Drying (125 °C)

The first requirement is the removal of solvent moisture without disrupting the mixture's homogeneity. The furnace maintains a steady 125 °C environment to evaporate water content. This prepares the material for chemical transformation by ensuring the precursors are dry and stable.

Stage 2: Carbonate Stabilization (200 °C)

Before the final oxide is formed, the material must undergo an intermediate transformation. By ramping the temperature to 200 °C, the furnace promotes the formation and stabilization of metal carbonates. This step is vital for setting the structural "skeleton" of the material before the organic templates are removed.

Stage 3: Calcination and Crystallization (300 °C)

The final stage is where the functional material is created. At 300 °C, two critical events occur simultaneously:

- Template Removal: Organic soft templates, specifically Pluronic F-127, are thermally decomposed and removed.

- Crystallization: The previously amorphous mixture converts into a robust, nanocrystalline mesoporous framework.

Why Precision Matters for Mesoporous Structures

Using a muffle furnace addresses the "deep need" of the synthesis: structural integrity during chemical change.

Managing Phase Transitions

The transition from an amorphous mixture to a crystalline solid generates internal stress. The programmable nature of the muffle furnace allows for a gradual evolution of the material structure. This prevents the rapid volume changes that would occur with uncontrolled heating, which often leads to the collapse of the mesopores.

Creating Reactive Frameworks

The goal is not just to create cobalt oxide, but to create a highly reactive form of it. The precise thermal ceiling of 300 °C ensures the material crystallizes fully without sintering (fusing together). This preserves the high surface area required for the material's final application.

Understanding the Trade-offs

While the muffle furnace is the ideal tool for this process, there are inherent limitations and risks to consider.

Sensitivity to Temperature Overshoot

The gap between the calcination temperature (300 °C) and temperatures that might induce sintering is relatively narrow. If the furnace is poorly calibrated or has significant thermal fluctuation, you risk overheating the sample. This can destroy the mesoporous architecture you worked to create.

Atmosphere Dependence

Standard muffle furnaces typically operate in an air environment (oxidative). While this is perfect for creating oxides like Co3O4 and burning off organic templates, it limits your ability to control surface chemistry if a non-oxidative or inert environment is ever required for surface modification.

Making the Right Choice for Your Goal

To maximize the quality of your mesoporous cobalt oxide, align your furnace settings with your specific objectives.

- If your primary focus is Structural Integrity: Ensure your furnace is programmed with slow ramp rates between the 125 °C, 200 °C, and 300 °C stages to minimize thermal shock.

- If your primary focus is Purity: Verify that the 300 °C stage is held long enough to fully decompose the Pluronic F-127 template, as residual organics will impede reactivity.

The success of your synthesis depends entirely on the furnace's ability to maintain the distinct separation between the stabilization and calcination phases.

Summary Table:

| Thermal Stage | Temperature (°C) | Primary Function | Structural Impact |

|---|---|---|---|

| Controlled Drying | 125 °C | Solvent removal | Ensures precursor homogeneity |

| Stabilization | 200 °C | Carbonate formation | Sets the structural "skeleton" |

| Calcination | 300 °C | Template removal & crystallization | Creates reactive nanocrystalline framework |

| Ramp Control | Programmable | Phase management | Prevents collapse of mesopores |

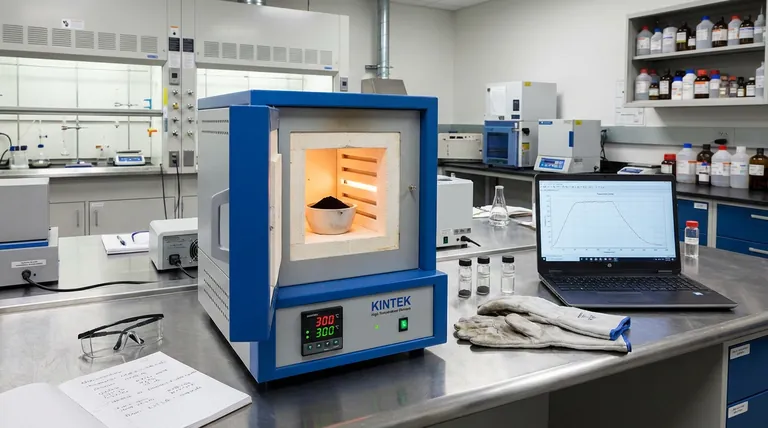

Elevate Your Material Synthesis with KINTEK Precision

Precision is the difference between a collapsed structure and a high-performance nanocrystalline framework. KINTEK provides the advanced thermal technology required for complex multi-stage protocols like Co3O4 synthesis.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory needs. Whether you require strict temperature uniformity or programmable ramp rates to preserve structural integrity, our high-temperature furnaces deliver the reliability your research demands.

Ready to optimize your thermal processing? Contact us today to consult with our experts on the perfect furnace solution for your lab.

Visual Guide

References

- Qingyang Wu, Marcus Einert. Soft-templated, mesoporous Co<sub>3</sub>O<sub>4</sub> thin films for electrocatalysis of the oxygen evolution reaction. DOI: 10.1039/d3ma01054f

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the common applications of the box furnace? Unlock Precise Heat Treatment for Your Lab

- How do high-temperature furnaces facilitate ZnZrOx and InZrOx catalysts? Optimize Your Solid Solution Synthesis

- What is the conclusion regarding the comparison between muffle furnaces and vacuum furnaces? Choose the Right Furnace for Your Process

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How do muffle furnaces assist in ash testing? Achieve Accurate Mineral Analysis for Quality Control

- How to keep samples in muffle furnace? A Step-by-Step Guide for Safe & Accurate Results

- How does a high-temperature muffle furnace contribute to the formation of the ZrO2-ZnO heterojunction?

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics