In essence, a box furnace is a highly versatile thermal processing tool used across industries and laboratories for heat treatment, materials testing, and high-temperature synthesis. Its common applications include the annealing, tempering, and quenching of small metal parts; the sintering of ceramics; and performing quality analysis in research settings.

The core value of a box furnace is not just its ability to get hot, but its capacity to provide precise, uniform heat to a static batch of material. This makes it the definitive choice for processes where consistency and repeatability are more critical than continuous throughput.

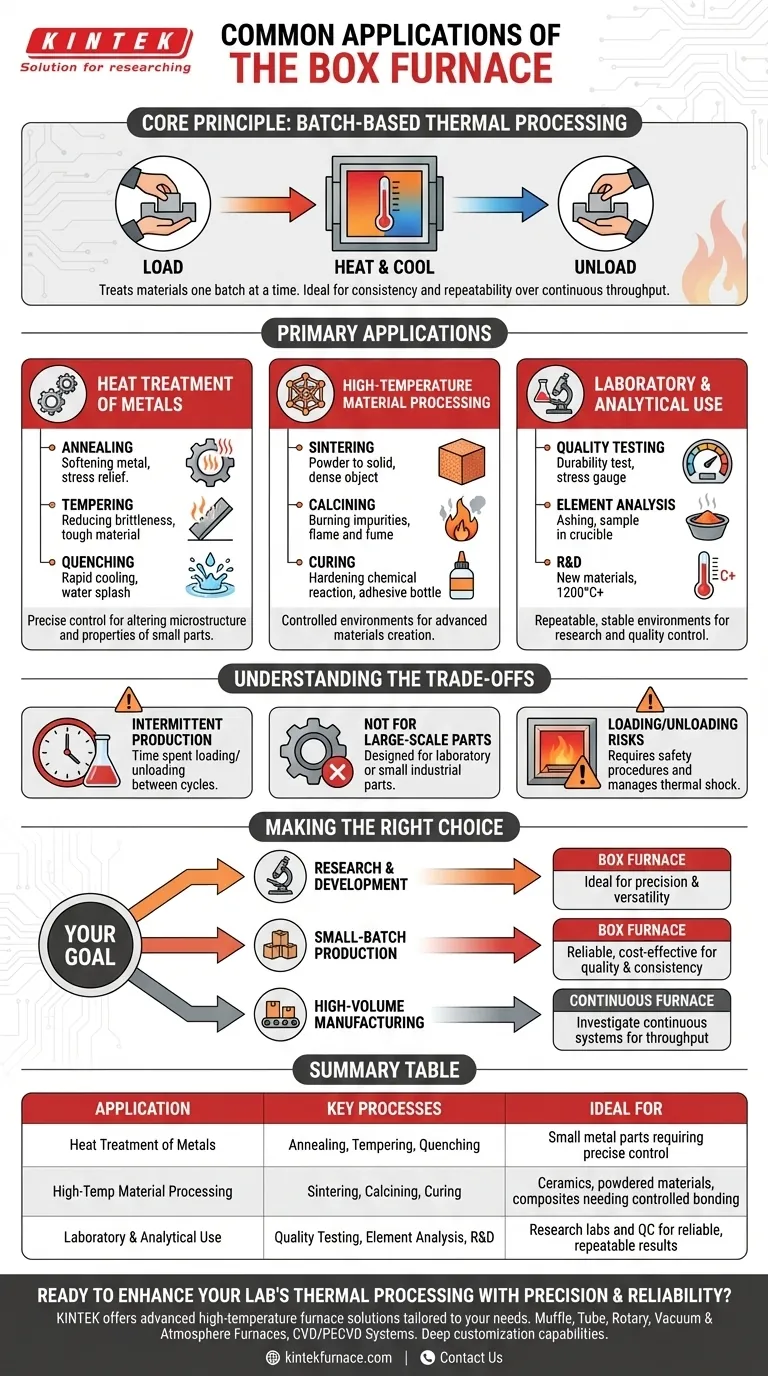

The Core Principle: Batch-Based Thermal Processing

A box furnace operates on a simple but powerful principle: treating materials one batch at a time. Unlike a continuous furnace where materials move through on a conveyor, a box furnace processes a static load within a self-contained chamber.

How It Works: The Load-Heat-Cool Cycle

Materials are loaded into the furnace through a single door. The furnace then executes a programmed heating, soaking (holding at temperature), and cooling profile. Once the cycle is complete, the door is opened and the finished batch is removed. This is known as intermittent production.

Key Advantage: Temperature Uniformity

Because the chamber is sealed and the workload does not move, a box furnace excels at providing highly uniform heat distribution. This ensures that every part in the batch receives the exact same thermal treatment, which is critical for consistent material properties.

Key Advantage: Unmatched Versatility

The simple, enclosed design allows a box furnace to handle a vast array of materials and processes. The same furnace can be used for annealing steel one day and sintering ceramics the next, simply by changing the temperature and time settings.

Primary Applications in Industry and Research

The unique characteristics of the box furnace make it indispensable for several key applications where precision is paramount.

Heat Treatment of Metals

This is a primary industrial use, especially for smaller components. The furnace's precise control is ideal for altering the microstructure of metals to achieve desired hardness, toughness, or ductility.

- Annealing: Heating and slowly cooling metal to soften it and improve machinability.

- Tempering: Heating a previously hardened part to a lower temperature to reduce brittleness.

- Quenching: Rapidly cooling a part after heating to lock in a hardened state.

High-Temperature Material Processing

Many advanced materials require carefully controlled high-temperature environments for their creation.

- Sintering: Heating powdered materials (like ceramics or metals) below their melting point to cause them to bond and form a solid, dense object.

- Calcining: Heating a material to a high temperature to burn off impurities or induce a phase transition.

- Curing: Using heat to trigger a chemical reaction to harden a material, such as an adhesive or composite.

Laboratory and Analytical Use

In research and quality control, repeatability is everything. Box furnaces provide the stable, controlled environment needed for reliable testing.

- Quality Testing: Subjecting materials or components to extreme temperatures to test their durability and performance.

- Element Analysis: Burning off organic matter from a sample (ashing) to analyze its inorganic content.

- Research & Development: Used in universities and scientific institutes for developing new materials and processes at temperatures often up to 1200°C or higher.

Understanding the Trade-offs

While incredibly useful, the box furnace is not the right tool for every job. Its design comes with inherent limitations.

The Constraint of Intermittent Production

The batch-based nature of a box furnace makes it unsuitable for high-volume, continuous manufacturing. The time spent loading, unloading, and cooling the furnace between cycles creates a bottleneck that conveyor-style furnaces avoid.

Not Ideal for Large-Scale Parts

Most box furnaces are designed for laboratory-scale samples or small industrial parts. Processing very large or heavy components requires specialized, larger, and often custom-built furnace solutions.

Careful Management of Loading/Unloading

Opening the door to a hot furnace introduces a significant temperature change and exposes the operator to heat. This requires established safety procedures and can induce thermal shock in highly sensitive materials if not managed correctly.

Making the Right Choice for Your Goal

Selecting a furnace depends entirely on your operational needs for precision, volume, and material type.

- If your primary focus is research and development: The precision, versatility, and repeatability of a box furnace make it an ideal choice for process development and material analysis.

- If your primary focus is small-batch production: A box furnace provides a highly reliable and cost-effective method for heat treating or processing components where quality and consistency are critical.

- If your primary focus is high-volume manufacturing: You should investigate continuous furnace systems, as the batch processing of a box furnace will limit your throughput.

Ultimately, understanding the box furnace's role as a precise, batch-oriented tool is the key to leveraging its power for your specific material processing needs.

Summary Table:

| Application | Key Processes | Ideal For |

|---|---|---|

| Heat Treatment of Metals | Annealing, Tempering, Quenching | Small metal parts requiring precise hardness and toughness control |

| High-Temperature Material Processing | Sintering, Calcining, Curing | Ceramics, powdered materials, and composites needing controlled bonding |

| Laboratory and Analytical Use | Quality Testing, Element Analysis, R&D | Research labs and quality control for reliable, repeatable results |

Ready to enhance your lab's thermal processing with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're in research, small-batch production, or need specialized heat treatment, our solutions ensure consistent performance and efficiency. Contact us today to discuss how we can support your projects and deliver the perfect furnace for your applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing