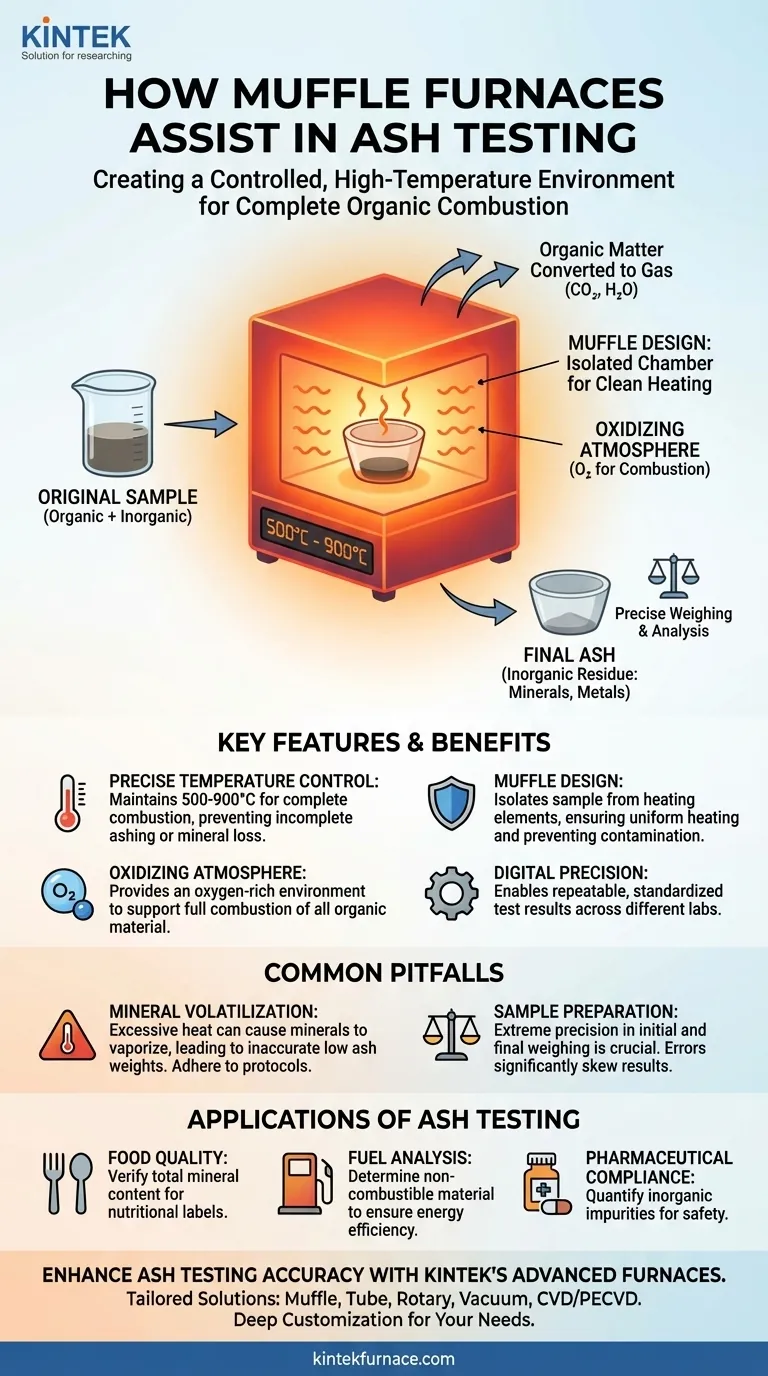

In essence, a muffle furnace assists in ash testing by creating an extremely hot, controlled environment to completely burn away all organic material from a sample. This process, known as incineration or ashing, leaves behind only the inorganic, non-combustible residue—the ash. The weight and composition of this ash can then be precisely analyzed to determine the quality, purity, and characteristics of the original substance.

The core function of a muffle furnace in ash testing is to provide a clean, high-temperature, and precisely controlled environment that ensures complete combustion of organic matter, thereby isolating the inorganic ash for accurate quantitative analysis.

The Fundamental Principle of Ashing

To understand the role of the muffle furnace, we must first understand the goal of ash testing. It is a process of separation designed to measure the total amount of inorganic minerals in a sample.

What is "Ash"?

Ash is the inorganic residue that remains after a substance is completely burned. It consists of minerals like calcium, potassium, magnesium, and other metallic and non-metallic elements that do not combust.

The Role of Complete Combustion

The primary goal is to remove all organic components—carbon, hydrogen, oxygen, and nitrogen—by converting them into gaseous byproducts like carbon dioxide and water vapor. A muffle furnace achieves this by maintaining high temperatures, typically between 500°C and 900°C, in the presence of air (oxygen).

Why Precise Temperature is Critical

Different materials require specific ashing temperatures and durations. If the temperature is too low, combustion will be incomplete, leaving unburnt carbon and yielding an inaccurate, artificially high ash weight. If it's too high, some minerals may volatilize (turn into vapor) and be lost, resulting in an artificially low ash weight.

How a Muffle Furnace Facilitates Accurate Ashing

A muffle furnace is specifically engineered to overcome the challenges of complete and clean combustion. Its design ensures the results are both repeatable and reliable.

The "Muffle" Design for Clean Heating

The term "muffle" refers to the furnace's inner chamber, which isolates the sample from the heating elements. This prevents direct contact with flames or contaminants from the heating source, ensuring the only thing affecting the sample is pure, radiant heat. This leads to uniform heating and prevents contamination of the ash.

Unwavering Temperature Control

Modern muffle furnaces use digital controllers to maintain a specific temperature with high accuracy. This allows technicians to follow standardized testing protocols (like those for food, fuel, or pharmaceuticals) precisely, ensuring that results are consistent and comparable across different labs and tests.

An Oxidizing Atmosphere

Ashing requires an oxygen-rich environment to support full combustion. The design of a muffle furnace allows for controlled airflow, ensuring the organic matter has enough oxygen to burn away completely, leaving only the pure mineral ash.

Common Pitfalls and Considerations

While essential, using a muffle furnace for ashing requires careful attention to detail. The accuracy of the final result depends on more than just the equipment itself.

The Risk of Mineral Volatilization

As mentioned, excessive heat can cause certain minerals, particularly chlorides and nitrates, to vaporize. This is the single most critical reason for adhering to established temperature protocols for specific materials.

Importance of Sample Preparation

The process starts before the sample even enters the furnace. It must be weighed with extreme precision using an analytical balance. Any error in the initial or final weight will directly and significantly skew the calculated ash percentage.

Time and Energy Use

Ashing is not an instantaneous process. It can take several hours to ensure complete combustion, making it a time-consuming and energy-intensive procedure. This must be factored into any laboratory workflow and budget.

Applying Ash Testing to Your Goal

The reason for performing an ash test dictates which aspect of the process is most critical.

- If your primary focus is food quality and nutrition: The goal is to verify the total mineral content listed on a nutritional label or to detect inorganic adulterants.

- If your primary focus is fuel analysis (e.g., coal): The goal is to determine the amount of non-combustible material, as high ash content reduces energy efficiency and can damage boilers.

- If your primary focus is pharmaceutical compliance: The goal is to quantify inorganic impurities in drug formulations, which is a critical step for regulatory approval and patient safety.

Ultimately, the muffle furnace serves as a high-precision tool for separating the combustible from the non-combustible, providing foundational data for quality, safety, and performance analysis.

Summary Table:

| Aspect | Role in Ash Testing | Key Benefit |

|---|---|---|

| Temperature Control | Maintains 500°C to 900°C for complete combustion | Prevents incomplete ashing or mineral loss |

| Muffle Design | Isolates sample from heating elements | Ensures uniform heating and prevents contamination |

| Oxidizing Atmosphere | Provides oxygen-rich environment | Supports full combustion of organic material |

| Digital Precision | Uses controllers for accurate temperature | Enables repeatable, standardized test results |

Enhance your laboratory's ash testing accuracy with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, improving efficiency and reliability in quality control. Contact us today to discuss how our products can benefit your specific applications in food, fuel, or pharmaceutical analysis!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis