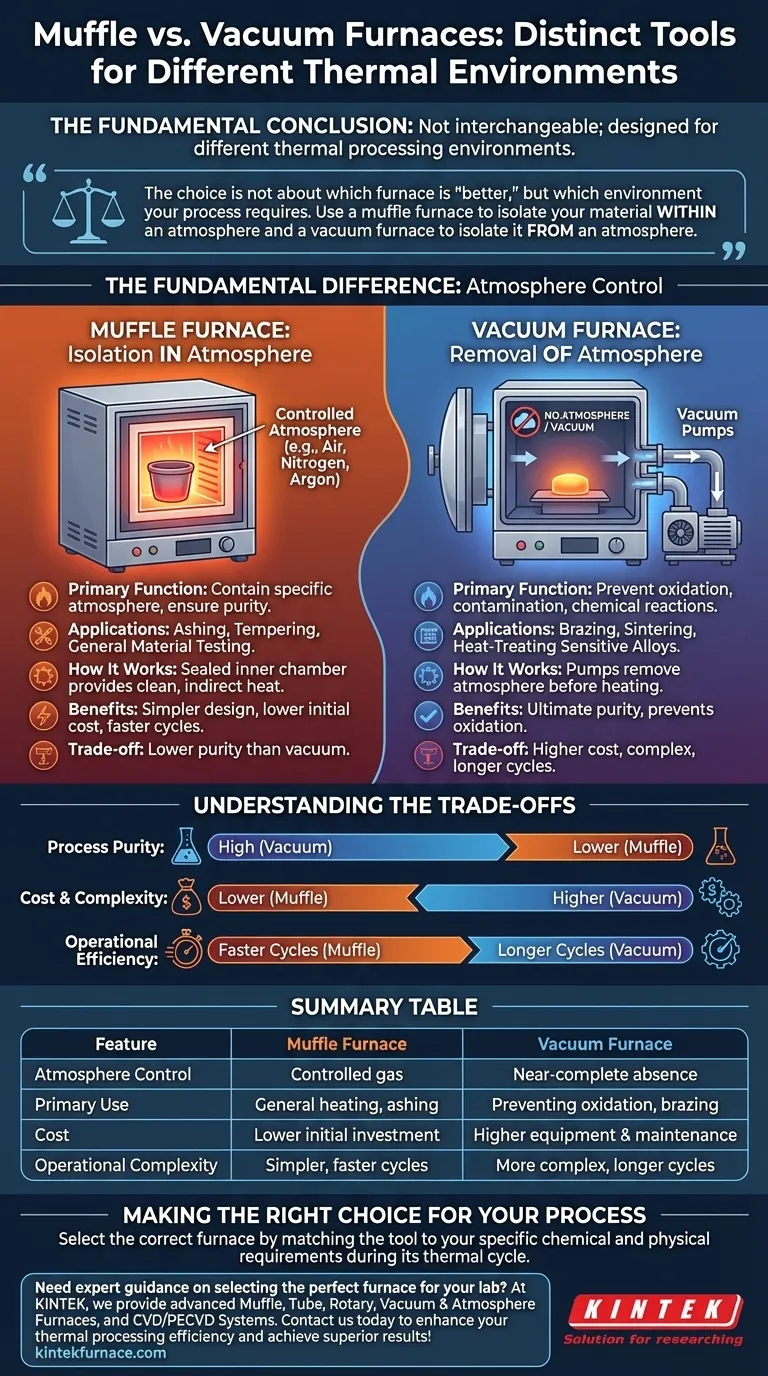

The fundamental conclusion is that a muffle furnace and a vacuum furnace are not interchangeable; they are distinct tools designed for fundamentally different thermal processing environments. A muffle furnace excels at providing uniform heat within a controlled gas atmosphere, while a vacuum furnace is specifically designed for processes that require the near-complete absence of an atmosphere to prevent oxidation and contamination.

The choice is not about which furnace is "better," but which environment your process requires. Use a muffle furnace to isolate your material within an atmosphere and a vacuum furnace to isolate it from an atmosphere.

The Fundamental Difference: Atmosphere Control

The core distinction between these two furnaces lies in how they manage the environment surrounding the material being heated. This single factor dictates their design, application, and cost.

How a Muffle Furnace Works: Isolation in Atmosphere

A muffle furnace uses a sealed inner chamber (the "muffle") to isolate the workpiece from the heating elements and any combustion byproducts. This design provides clean, indirect heat.

The key function is to contain a specific atmosphere, which could be normal air or a controlled gas like nitrogen or argon, ensuring it remains pure and stable around the sample.

This makes it ideal for applications like ashing, tempering, and general material testing where uniform heating in a specific gas is the primary goal.

How a Vacuum Furnace Works: Removal of Atmosphere

A vacuum furnace is designed for the opposite purpose: to remove the atmosphere from the chamber. It uses a system of pumps to evacuate air and other gases before the heating cycle begins.

The primary benefit is preventing high-temperature oxidation, contamination, and other unwanted chemical reactions that occur when reactive materials are heated in the presence of air.

Processes like brazing, sintering of exotic metals, and heat-treating highly sensitive alloys absolutely require a vacuum environment to succeed.

Understanding the Trade-offs

Choosing between these furnaces involves a clear trade-off between process requirements, cost, and operational complexity. Your material's sensitivity is the deciding factor.

Process Purity vs. Simplicity

If your material will be damaged by exposure to oxygen or other gases at high temperatures, a vacuum furnace is non-negotiable. It provides the ultimate level of purity.

For most other applications where the goal is simply uniform heat treatment, a muffle furnace offers a simpler, more direct solution.

Initial Cost and Complexity

Muffle furnaces are mechanically simpler, resulting in a significantly lower initial investment and less demanding maintenance schedules.

Vacuum furnaces are inherently more complex. The addition of vacuum pumps, seals, gauges, and control systems substantially increases the equipment and ongoing maintenance costs, especially for high-vacuum systems.

Operational Efficiency

Muffle furnaces are generally straightforward to operate and have faster cycle times, as there is no need to pump down a vacuum.

Vacuum furnace cycles are often longer due to the time required to achieve the target vacuum level before heating and to safely cool the chamber before opening. For continuous, high-volume production, other designs like rotary furnaces may offer better throughput than either standard muffle or vacuum batch furnaces.

Making the Right Choice for Your Process

Your decision must be driven by the specific chemical and physical requirements of your material during its thermal cycle.

- If your primary focus is preventing oxidation, degassing, or reactions in sensitive materials: You must use a vacuum furnace to remove the reactive atmosphere.

- If your primary focus is general heating, ashing, or heat treatment in air or an inert gas: A muffle furnace is the more direct, reliable, and cost-effective solution.

- If your primary focus is budget and operational simplicity for non-reactive processes: The muffle furnace is the clear and superior choice.

Ultimately, selecting the correct furnace means precisely matching the tool to the required processing environment.

Summary Table:

| Feature | Muffle Furnace | Vacuum Furnace |

|---|---|---|

| Atmosphere Control | Controlled gas (e.g., air, inert gases) | Near-complete absence of atmosphere |

| Primary Use | General heating, ashing, tempering | Preventing oxidation, brazing, sintering |

| Cost | Lower initial investment | Higher equipment and maintenance costs |

| Operational Complexity | Simpler, faster cycles | More complex, longer cycles |

Need expert guidance on selecting the perfect furnace for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to enhance your thermal processing efficiency and achieve superior results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination