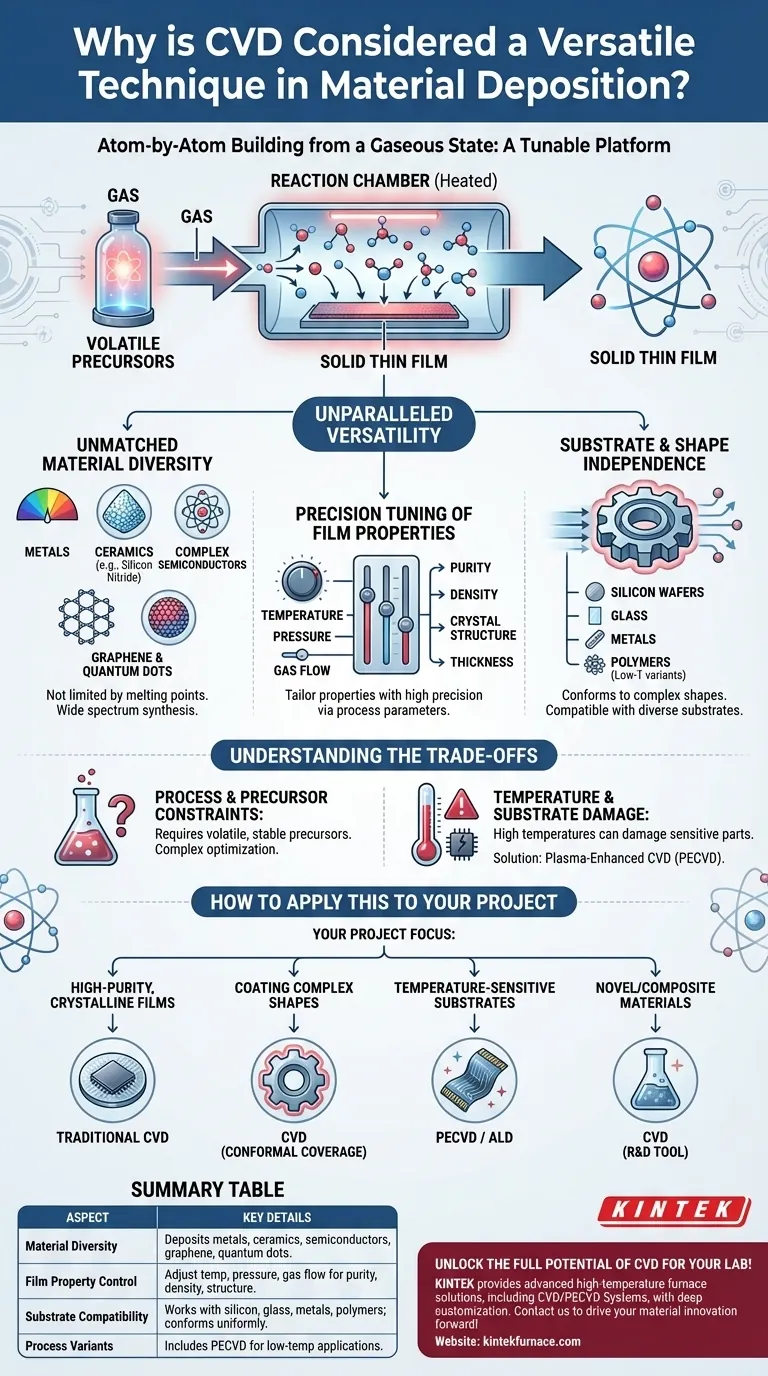

At its core, Chemical Vapor Deposition (CVD) is considered exceptionally versatile because it builds materials atom-by-atom from a gaseous state. This fundamental approach allows it to be adapted for an unparalleled range of materials, substrates, and final film properties, moving far beyond a single deposition method into a highly tunable material fabrication platform.

The true versatility of CVD is not just in the wide variety of materials it can deposit, but in its precise control over the entire process—from the chemical precursors to the final atomic structure of the film. This makes it a foundational tool for both mass production and cutting-edge materials science.

The Core Principles of CVD's Adaptability

CVD's flexibility stems from its basic mechanism: volatile chemical precursors are introduced into a reaction chamber where they decompose or react on a heated substrate, forming a solid thin film. The versatility arises from the ability to control every variable within this process.

Unmatched Material Diversity

Because the deposition originates from gas-phase chemistry, CVD is not limited by the melting points or sputtering characteristics of a source material. This allows for the synthesis of an incredibly broad spectrum of materials.

This includes metals, ceramics (like silicon nitride), and complex semiconductors. It is also a leading method for producing advanced materials like graphene and quantum dots, showcasing its role in both industrial and research settings.

Precision Tuning of Film Properties

By carefully manipulating process parameters, engineers can tailor the final properties of the deposited film with high precision.

Controlling variables like temperature, pressure, and precursor gas flow rates allows for direct influence over the film's purity, density, crystal structure, and thickness. This means a single CVD system can be configured to produce a hard, abrasion-resistant coating or an ultra-pure, crystalline layer for electronics.

Substrate and Shape Independence

The gaseous precursors naturally flow to conform to any exposed surface within the reaction chamber. This makes CVD exceptionally effective at coating complex, non-planar shapes uniformly.

Furthermore, the process is compatible with a vast range of substrate materials, including silicon wafers, glass, metals, and even temperature-sensitive polymers in certain low-temperature CVD variants.

Understanding the Trade-offs

While powerful, the versatility of CVD comes with inherent complexities. It is not a universal solution, and understanding its limitations is critical for proper application.

Process and Precursor Constraints

The primary requirement for CVD is the availability of suitable volatile precursors—chemicals that can be readily vaporized and transported. For some elements or compounds, finding a stable, non-toxic, and efficient precursor can be a significant challenge.

Additionally, achieving the desired film properties often requires extensive process optimization. The interplay between temperature, pressure, and gas chemistry is complex and demands significant expertise to master.

Temperature and Substrate Damage

Traditional thermal CVD processes often operate at very high temperatures (hundreds or even over 1000°C) to drive the necessary chemical reactions.

These temperatures can easily damage or destroy sensitive substrates, such as plastics or pre-processed semiconductor devices. This limitation has driven the development of variants like Plasma-Enhanced CVD (PECVD), which use plasma to enable reactions at much lower temperatures, thereby expanding its applicability.

How to Apply This to Your Project

Choosing to use CVD depends entirely on the desired outcome for your material or device.

- If your primary focus is high-purity, crystalline films: The precise control offered by traditional CVD is ideal for demanding applications like semiconductor fabrication.

- If your primary focus is coating complex shapes uniformly: CVD's gas-phase nature provides superior conformal coverage compared to line-of-sight methods like sputtering.

- If your primary focus is coating temperature-sensitive substrates: You must look to lower-temperature variants like PECVD or Atomic Layer Deposition (ALD) to avoid damaging your part.

- If your primary focus is creating novel or composite materials: The chemical flexibility of CVD makes it a powerful research and development tool for material discovery.

Ultimately, understanding CVD as a tunable chemical platform, rather than a single technique, is the key to leveraging its power for material innovation.

Summary Table:

| Aspect | Key Details |

|---|---|

| Material Diversity | Deposits metals, ceramics, semiconductors, graphene, and quantum dots from gas-phase chemistry. |

| Film Property Control | Adjust temperature, pressure, and gas flow for purity, density, crystal structure, and thickness. |

| Substrate Compatibility | Works with silicon, glass, metals, and polymers; conforms to complex shapes uniformly. |

| Process Variants | Includes Plasma-Enhanced CVD (PECVD) for low-temperature applications to protect sensitive substrates. |

Unlock the full potential of Chemical Vapor Deposition for your lab! Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need high-purity films, uniform coatings on complex shapes, or tailored solutions for temperature-sensitive substrates, we're here to help. Contact us today to discuss how our CVD systems can drive your material innovation forward!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection