Controlled and consistent heating is the defining characteristic of a muffle furnace, and it is essential for ensuring process integrity and achieving reliable, repeatable outcomes. Without it, any results from scientific testing or material treatment would be unreliable, as you could never be certain if variations were due to the sample or to inconsistent furnace performance. This level of control is what makes the muffle furnace a cornerstone of modern laboratories and industrial processes.

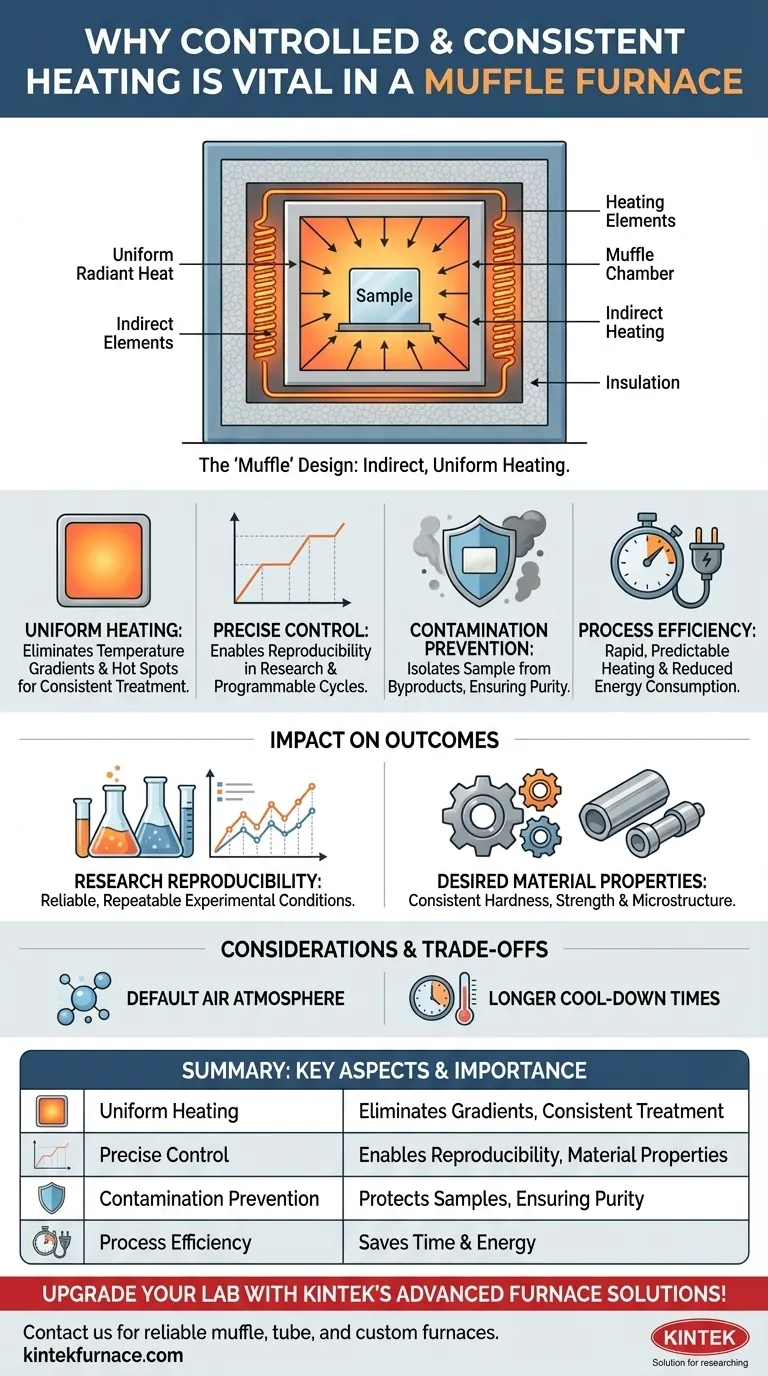

The core value of a muffle furnace lies in its design, which physically separates the material being heated from the raw heating elements. This "muffle" chamber ensures uniform, indirect heating, which eliminates temperature variations and prevents contamination, leading to highly accurate and reproducible results.

The Principle of Uniform Heating

The reliability of a muffle furnace stems directly from its ability to heat a sample evenly from all sides. This is not an accidental feature but a deliberate engineering outcome designed to solve the common problem of "hot spots" found in simpler heating devices.

Eliminating Temperature Gradients

A temperature gradient is a variation in temperature across a sample. If one part of your material is at 800°C while another is at 820°C, the resulting properties or analytical measurements will be inconsistent and inaccurate.

Muffle furnaces are designed to create a highly uniform thermal environment, bathing the sample in consistent radiant heat. This eliminates gradients and ensures the entire object experiences the exact same thermal history.

The Role of the Insulated Muffle

The term "muffle" refers to the furnace's inner chamber, which isolates the sample from the direct, harsh heat of the combustion flames or electrical elements.

Instead of being exposed directly, the sample is heated by uniform radiation from the chamber's hot walls. This indirect heating method is inherently more even and controllable than direct exposure.

Preventing Sample Contamination

This separation also serves another critical function: it protects the sample from byproducts of combustion or off-gassing from the heating elements.

For sensitive analytical procedures like determining the ash content of a material, or for creating high-purity alloys, this contamination-free environment is non-negotiable.

The Impact of Precise Control on Outcomes

Uniformity is one half of the equation; the other is the ability to precisely control the temperature over time. This includes the rate of heating (ramp rate), the duration at peak temperature (soak time), and the cooling rate.

Ensuring Reproducibility in Research

In a scientific setting, reproducibility is paramount. Controlled heating allows researchers to perfectly replicate thermal conditions from one experiment to the next.

For example, when testing how a new alloy behaves after exposure to high temperatures, engineers can trust that the furnace is producing the exact specified conditions, making the test results valid and comparable.

Achieving Desired Material Properties

In industrial processes like annealing, tempering, or sintering, the final physical properties of the material are a direct result of the thermal cycle it undergoes.

Precise control ensures that every part in a batch receives the exact same heat treatment. This guarantees consistent hardness, strength, and microstructure, which is critical for quality control in manufacturing everything from steel components to ceramic parts.

Enhancing Process Efficiency

Modern muffle furnaces offer rapid and predictable heating, often reaching temperatures over 1000°C in about an hour. Well-insulated chambers retain this heat effectively, reducing energy consumption.

This combination of speed and efficiency saves time and operational costs, making processes more economical.

Understanding the Trade-offs

While exceptional for its primary purpose, the design of a muffle furnace presents certain considerations that are important to understand for proper application.

Default Atmosphere is Air

A standard muffle furnace heats samples in the ambient air within its sealed chamber. If your process requires a specific inert (like argon) or reactive atmosphere, you will need a more specialized and costly retort or tube furnace designed for atmosphere control.

Thermal Mass and Cool-Down Times

The heavy insulation that ensures temperature uniformity and energy efficiency also retains a great deal of heat. This means that muffle furnaces can have long cool-down cycles. This is a trade-off to consider for high-throughput applications where rapid cycling is necessary.

Making the Right Choice for Your Goal

The importance of controlled heating depends entirely on your objective. Use these guidelines to frame your needs.

- If your primary focus is analytical testing (e.g., ashing, gravimetric analysis): Absolute temperature uniformity and control are non-negotiable to ensure your results are accurate and legally defensible.

- If your primary focus is materials processing (e.g., heat treating, annealing): You need precise control over ramp rates and soak times to guarantee the final material properties are consistent across the entire batch.

- If your primary focus is process development: The furnace's ability to reliably repeat thermal cycles allows you to isolate variables and confidently assess the impact of your changes.

Ultimately, understanding the importance of controlled heating empowers you to produce results you can trust, every single time.

Summary Table:

| Key Aspect | Importance |

|---|---|

| Uniform Heating | Eliminates temperature gradients for consistent sample treatment |

| Precise Control | Enables reproducibility in experiments and material properties |

| Contamination Prevention | Protects samples from byproducts, ensuring purity |

| Process Efficiency | Reduces energy use and saves time with rapid, predictable heating |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable muffle, tube, rotary, vacuum, atmosphere, and CVD/PECVD furnaces. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering consistent, contamination-free heating for accurate results. Contact us today to discuss how our furnaces can enhance your process integrity and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis