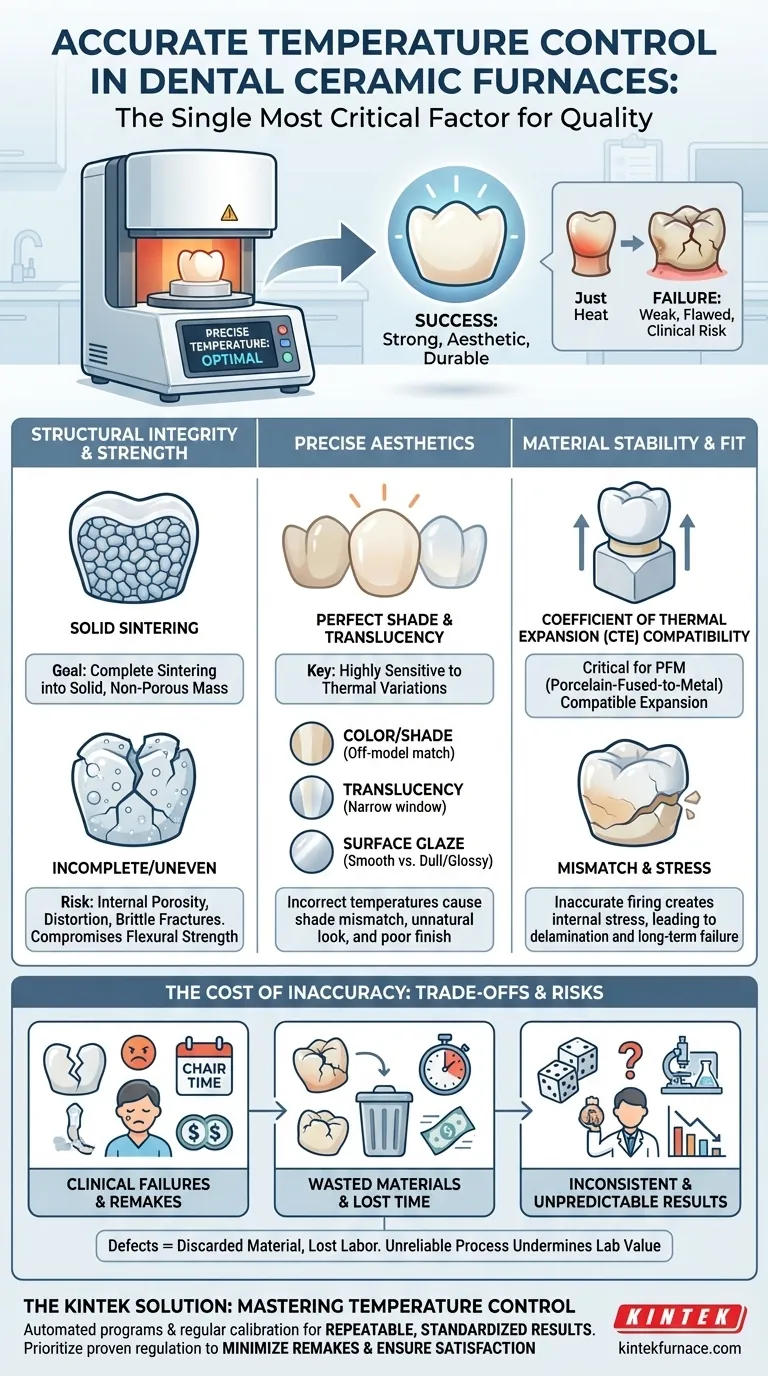

In short, accurate temperature control is the single most critical factor in producing a dental ceramic restoration that is strong, aesthetically pleasing, and durable. Without it, the physical and visual properties of the ceramic are compromised, leading to defects that can cause clinical failure.

In dental ceramics, temperature is not just heat; it is a precision instrument. Even minor deviations from the target firing cycle can cascade into significant problems, affecting everything from the restoration's strength and color to its long-term viability in the patient's mouth.

The Direct Impact of Temperature on Restoration Quality

A ceramic furnace does more than simply heat porcelain. It executes a precise, time-sensitive thermal program that transforms ceramic powder into a dense, solid, and stable final restoration. Every stage of this process is temperature-dependent.

Ensuring Structural Integrity and Strength

A primary goal of the firing cycle is to sinter ceramic particles into a solid, non-porous mass. If the temperature is too low or uneven, this process remains incomplete, creating internal porosity that severely weakens the final crown or veneer.

Conversely, if the temperature is too high, the ceramic can become distorted or brittle. Precise control is essential to achieve maximum flexural strength and prevent cracks or fractures under the stress of chewing.

Achieving Precise Aesthetics

The final appearance of a restoration is directly tied to the firing temperature. Key aesthetic properties are highly sensitive to thermal variations.

- Color and Shade: Incorrect temperatures can cause the shade to be off-model, failing to match the patient's adjacent teeth.

- Translucency: The glass-like translucency that makes a restoration look natural only develops within a very narrow temperature window.

- Surface Glaze: The final glaze firing, which gives the restoration its smooth, stain-resistant surface, requires absolute temperature accuracy to avoid a dull or overly glossy finish.

Guaranteeing Material Stability and Fit

Temperature controls the coefficient of thermal expansion (CTE) of the ceramic. This is especially critical for porcelain-fused-to-metal (PFM) crowns, where the ceramic and the metal substructure must expand and contract at compatible rates.

A mismatch, caused by inaccurate firing, can create immense internal stress. This can lead to delamination (porcelain chipping off the metal) or fractures, often long after the restoration has been placed.

Understanding the Trade-offs: The Cost of Inaccuracy

Investing in a furnace with poor temperature regulation, or failing to maintain an existing one, introduces significant risks and costs that go far beyond the initial price of the equipment.

Clinical Failures and Remakes

The most significant cost of inaccurate firing is clinical failure. A restoration that fractures, discolors, or does not fit properly must be remade.

This not only doubles the material and labor costs but also requires additional chair time for the dentist and patient, damaging the reputation of the lab and the practice.

Wasted Materials and Lost Time

Defects like bubbles, distortion, or porosity are often the direct result of temperature control issues. These flawed restorations must be discarded, wasting expensive ceramic materials and valuable technician time.

Inconsistent and Unpredictable Results

Without reliable temperature control, every firing cycle becomes a gamble. This lack of predictability makes it impossible to consistently produce high-quality work, undermining a dental lab's core value proposition.

Automated programs and regular calibration are not luxuries; they are essential for achieving repeatable, standardized results on which your business depends.

Making the Right Choice for Your Goal

When evaluating a ceramic furnace, prioritize its ability to deliver and maintain precise temperatures over all else.

- If your primary focus is clinical success and reliability: Invest in a furnace with proven, automated temperature regulation and a robust calibration process to minimize remakes and ensure patient satisfaction.

- If your primary focus is high-end aesthetics: Demand a furnace capable of extremely fine temperature control to consistently achieve the desired color, translucency, and surface texture for all-ceramic restorations.

- If your primary focus is lab efficiency and profitability: Recognize that consistent temperature control directly reduces material waste and costly remakes, improving your bottom line.

Ultimately, mastering temperature control transforms the firing process from an art into a reliable science, ensuring every restoration meets the highest standards of quality.

Summary Table:

| Aspect | Impact of Accurate Temperature Control |

|---|---|

| Structural Integrity | Prevents porosity and fractures, ensuring strong restorations |

| Aesthetics | Achieves precise color, translucency, and glaze for natural looks |

| Material Stability | Maintains coefficient of thermal expansion for long-term fit and durability |

Upgrade your dental lab with KINTEK's precision high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures your unique experimental needs are met, delivering reliable temperature control for strong, aesthetically perfect, and durable ceramic restorations. Contact us today to enhance your lab's efficiency and reduce costly remakes!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations