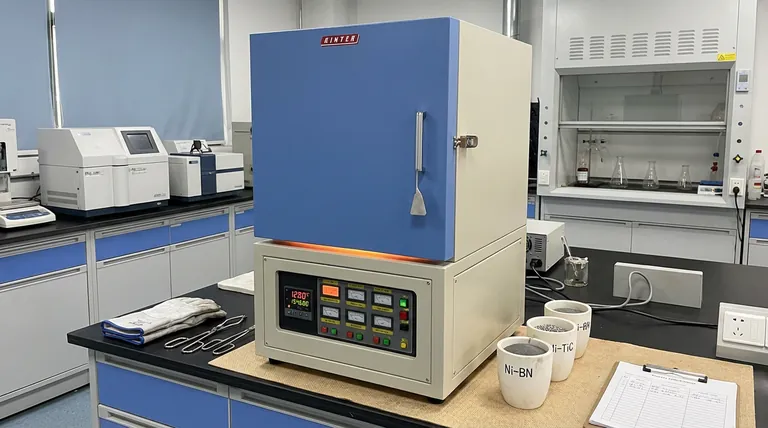

A muffle furnace is utilized for the high-temperature preheating of Ni-BN or Ni-TiC powder mixtures to ensure the absolute dehydration and degassing of the material prior to cladding. By subjecting the powders to temperatures around 1200°C for extended periods, typically up to 20 hours, the furnace eliminates deep-seated moisture and volatile impurities that would otherwise cause catastrophic defects during the coating process.

The rapid heating involved in cladding turns residual moisture into pressurized steam instantly. A muffle furnace prevents this by rigorously removing all volatiles beforehand, ensuring the final coating is dense, defect-free, and structurally sound.

The Mechanics of Defect Prevention

Eliminating Moisture and Volatiles

The primary function of the muffle furnace in this context is deep purification.

Powder mixtures like Ni-BN (Nickel-Boron Nitride) and Ni-TiC (Nickel-Titanium Carbide) are porous and naturally hygroscopic. They absorb moisture from the atmosphere which cannot be removed by simple surface drying.

The furnace provides a stable thermal environment at approximately 1200°C.

This high temperature must be maintained for extended durations, often reaching 20 hours. This ensures that not only surface water but also chemically bound moisture and other volatile impurities are completely driven out of the powder matrix.

preventing Rapid Vaporization Defects

This preheating step is dictated by the requirements of the subsequent process: microwave cladding.

Microwave cladding generates heat extremely rapidly. If moisture remains within the powder, it vaporizes instantly upon exposure to microwave energy.

This rapid expansion of gas creates internal pressure.

Without the preheating step, this gas becomes trapped in the solidifying metal, resulting in pores and bubbles. These defects significantly weaken the mechanical properties and corrosion resistance of the final coating.

Understanding the Trade-offs

Process Bottlenecks

While essential for quality, utilizing a muffle furnace for this purpose introduces a significant time constraint.

The requirement for a 20-hour cycle at 1200°C creates a bottleneck in production flow compared to the relatively fast cladding process itself.

Energy Consumption

The energy demand for maintaining such high temperatures for long durations is substantial.

Operators must weigh the cost of energy against the cost of scrapped parts due to porosity. There is no "shortcut" here; reducing temperature or time significantly increases the risk of coating failure.

Making the Right Choice for Your Goal

The use of a muffle furnace is a critical quality control gate in powder metallurgy cladding. Depending on your operational priorities, consider the following:

- If your primary focus is Coating Integrity: Adhere strictly to the 1200°C/20-hour protocol to guarantee zero porosity and maximum density in the final layer.

- If your primary focus is Process Efficiency: Do not attempt to shorten the heating duration; instead, batch process larger quantities of powder during the preheating phase to ensure a steady supply for the faster cladding station.

Success in high-quality cladding relies not just on the application method, but on the rigorous preparation of the raw materials.

Summary Table:

| Feature | Specification | Purpose |

|---|---|---|

| Powder Types | Ni-BN & Ni-TiC | Base materials for cladding |

| Preheating Temp | Approx. 1200°C | Complete degassing & dehydration |

| Duration | Up to 20 Hours | Removal of deep-seated moisture |

| Goal | Defect Prevention | Eliminate pores, bubbles, and cracks |

| Process Step | Pre-cladding Stage | Ensures coating density and integrity |

Elevate Your Material Integrity with KINTEK

Don't let moisture compromise your cladding quality. KINTEK provides high-performance, customizable Muffle, Tube, Rotary, Vacuum, and CVD systems engineered to withstand rigorous 1200°C cycles. Our lab high-temp furnaces are backed by expert R&D and manufacturing, ensuring your powder mixtures are perfectly prepared for defect-free results.

Ready to optimize your heat treatment process? Contact our specialists today to find the ideal thermal solution for your unique laboratory or industrial needs.

References

- Laith Jasim, Ankit Meheta. Advancing Surface Hardness and Wear Resistance: Microwave-Assisted Cladding of Ni-TiC Mixture onto SS-304. DOI: 10.1051/e3sconf/202450701017

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a muffle furnace play during the calcination of Ni/Al2O3 catalysts? Optimize Your Catalyst Stability

- What should be avoided when operating a muffle furnace? Key Safety Tips to Prevent Damage and Hazards

- What is the specific role of a Muffle Furnace in processing solar cell coatings? Unlock Superior Durability and Efficiency

- Why is input voltage an important factor in selecting a muffle furnace? Ensure Safety and Performance for Your Lab

- Why is a laboratory muffle furnace core to CCT nanocatalyst prep? Optimize Your Calcination Results

- What role does a laboratory muffle furnace play in the determination of phosphorus content? Essential Dry Ashing Guide

- What role does a muffle furnace play in the preparation of Cu-MnOx/GF catalytic electrodes? | Enhanced Synthesis Guide

- Why is an industrial-grade muffle furnace required for kaolin calcination? Ensure Precise Structural Transformation