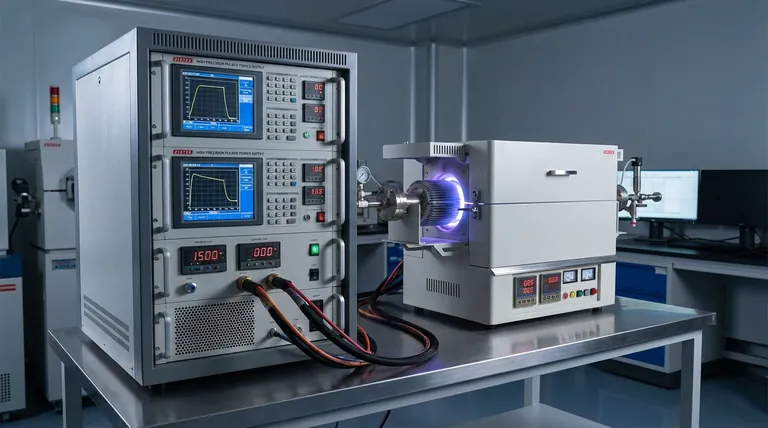

A high-precision pulsed power supply is the operational heart of High Power Impulse Magnetron Sputtering (HIPIMS) nitriding. It is strictly required to generate the short, high-density current pulses necessary to highly ionize the working gas. Without this precision, the system cannot achieve the specific plasma environment needed to enhance chemical activity while simultaneously preventing target overheating.

Core Takeaway The power supply serves as a sophisticated control mechanism, not just an energy source. Its ability to decouple plasma density from the discharge duty cycle allows for the creation of abundant active nitrogen ions for surface treatment without the thermal damage associated with continuous high-power operation.

The Mechanics of Enhanced Ionization

Achieving High Current Density

The primary function of the power supply is to generate extremely short pulses of energy.

By compressing energy into these brief windows, the system achieves a peak current density far higher than standard sputtering methods.

Creation of Active Nitrogen Species

This high current density is the catalyst for chemically active plasma.

It forces the working gas to undergo intense ionization.

This process produces a significant quantity of both active molecular nitrogen ions ($N_2^+$) and atomic nitrogen ions ($N^+$), which are essential for effective nitriding.

Thermal Management and Process Control

Decoupling Density from Heat

A major challenge in high-power sputtering is managing the thermal load on the target material.

High precision allows for the independent adjustment of plasma density and the discharge duty cycle.

This means you can maintain a high density of ions (for reactivity) while keeping the "on-time" of the pulse short enough to prevent target overheating.

Preventing Target Damage

If the power supply lacks precision, the distinct separation between pulse and cooling time blurs.

This can lead to thermal runaway, where the target melts or degrades rather than sputtering efficiently.

Precise control ensures the target remains chemically active but physically stable.

Industrial Application and Uniformity

Supporting Multi-Source Systems

In industrial settings, systems often utilize four-cathode setups with multiple magnetron targets (such as chromium or niobium).

A precise power supply coordinates these sources to produce consistent high-density metal and gas ion fluxes.

Uniformity on Complex Geometries

The combination of high-precision power and planetary rotating bases allows for uniform treatment of complex 3D shapes.

The highly ionized plasma environment ensures that even difficult-to-reach surfaces receive consistent nitriding, facilitating large-scale efficient production.

Understanding the Operational Trade-offs

Complexity of Parameter Optimization

While high precision offers control, it introduces complexity in process setup.

Operators must carefully balance pulse duration, frequency, and voltage; incorrect settings can lead to unstable discharges or insufficient ionization.

The Sensitivity of Duty Cycles

The advantage of independent duty cycle adjustment is also a potential point of failure.

If the duty cycle is set too high in an attempt to increase deposition rates, the cooling phase is compromised.

This negates the thermal benefits of HIPIMS, leading to potential equipment damage or poor coating quality.

Making the Right Choice for Your Goal

To maximize the effectiveness of HIPIMS nitriding, align your power supply settings with your specific production objectives.

- If your primary focus is Surface Hardness: Prioritize settings that maximize peak current density to generate the highest possible concentration of atomic nitrogen ions.

- If your primary focus is Component Longevity: Focus on optimizing the discharge duty cycle to maintain high plasma activity while strictly limiting the thermal load on the target.

- If your primary focus is Complex Geometry: Ensure your power supply supports multi-source synchronization to maintain uniform plasma density across rotating, three-dimensional workpieces.

Precision in power delivery is the difference between a standard coating and a chemically superior surface modification.

Summary Table:

| Feature | Necessity in HIPIMS Nitriding | Benefit to Process |

|---|---|---|

| Current Density | Generates high-density current pulses | Maximizes ionization of $N_2$ and $N^+$ ions |

| Thermal Control | Decouples plasma density from duty cycle | Prevents target overheating and melting |

| Pulse Precision | High-speed switching and timing control | Maintains physical stability of target materials |

| Ionization Species | Creates abundant active molecular nitrogen | Enhances chemical activity for harder surfaces |

| Multi-Source Sync | Coordinates multiple magnetron targets | Ensures uniformity on complex 3D geometries |

Transform Your Surface Engineering with KINTEK Precision

Don't let thermal instability or low ionization limit your coating quality. KINTEK’s high-precision power systems are designed to meet the rigorous demands of HIPIMS nitriding, offering the control needed to decouple plasma density from thermal load.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for your unique research or industrial needs. Whether you are aiming for superior surface hardness or uniform treatment of complex 3D geometries, our team is ready to provide the specialized equipment you require.

Contact KINTEK today to discuss your custom furnace and power supply solutions!

Visual Guide

References

- Arutiun P. Ehiasarian, P.Eh. Hovsepian. Novel high-efficiency plasma nitriding process utilizing a high power impulse magnetron sputtering discharge. DOI: 10.1116/6.0003277

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does a PACVD system prepare friction-reducing layers? Enhance Surface Lubricity with Plasma-Assisted CVD

- What is the difference between sputtering and PECVD? Choose the Right Thin Film Deposition Method

- What are the applications of silicon nitride (SiN) deposited via PECVD? Unlock Versatile Thin-Film Solutions

- How does PECVD contribute to microelectronics and MEMS devices? Enable Low-Temperature Thin Film Deposition

- What role does PECVD play in solar cell production? Boost Efficiency with Advanced Thin-Film Deposition

- How did PECVD systems evolve over time? From Batch to Single-Wafer for Precision

- What are the advantages of plasma CVD compared to other processes? Achieve Lower-Temp, High-Quality Film Deposition

- What are the key features of PECVD equipment? Unlock Low-Temperature Thin Film Deposition