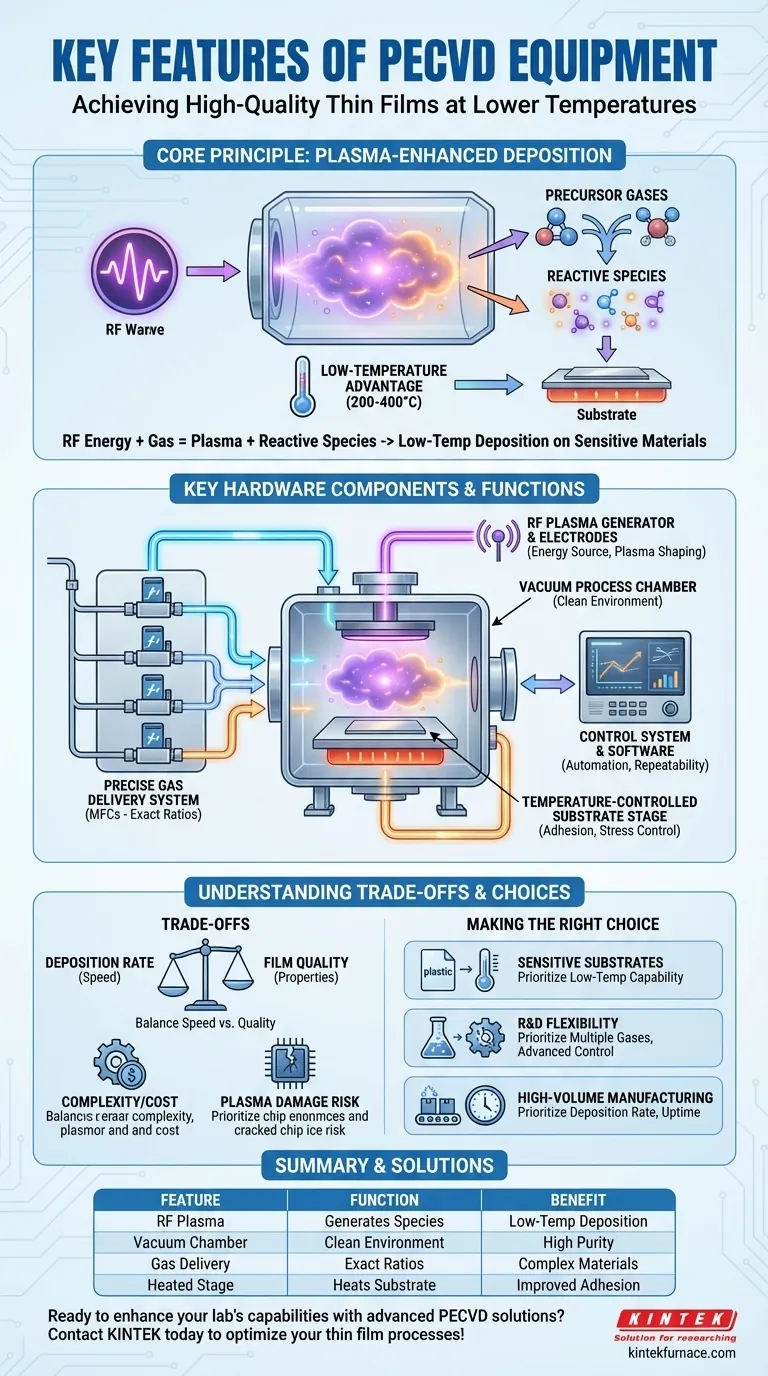

At its core, the key features of Plasma-Enhanced Chemical Vapor Deposition (PECVD) equipment are all designed to achieve one primary goal: depositing high-quality thin films at significantly lower temperatures than traditional methods. The essential features that enable this are a radio frequency (RF) plasma source, a vacuum process chamber, a precise gas delivery system, and a temperature-controlled substrate stage. These components work together to use plasma energy, rather than just heat, to drive the film-forming chemical reactions.

The fundamental value of PECVD is not just its list of components, but its ability to decouple the deposition process from high temperatures. This allows for the creation of durable, high-performance films on temperature-sensitive materials that would be damaged or destroyed by conventional deposition techniques.

The Core Principle: Plasma-Enhanced Deposition

The "PE" in PECVD is the defining feature. Understanding how the plasma works is key to understanding the entire system and its advantages.

What is Plasma and Why Does It Matter?

A plasma is a state of matter, often called the fourth state, where a gas is energized until its atoms are broken into a mix of ions and energetic electrons. In a PECVD system, a radio frequency (RF) generator applies energy to low-pressure precursor gases inside the chamber, creating this plasma.

These highly energetic electrons are the true workhorses of the process. They collide with the stable gas molecules and break them down into highly reactive species, or radicals.

The Low-Temperature Advantage

Traditional Chemical Vapor Deposition (CVD) relies solely on high thermal energy (often >600°C) to break down precursor gases and initiate reactions on the substrate surface.

PECVD replaces most of this thermal energy with energy from the plasma. Because the reactive species are already created within the plasma, the substrate only needs to be heated moderately (typically 200-400°C) to promote good film adhesion and quality. This makes it ideal for coating plastics, polymers, and complex microelectronic devices.

Key Hardware Components and Their Function

A PECVD system is an integrated set of subsystems, each with a critical role in controlling the deposition environment and resulting film properties.

The Process Chamber and Vacuum System

This is the sealed enclosure where the deposition occurs. It is connected to a powerful vacuum system capable of pumping the chamber down to a very low base pressure. This ensures a clean, controlled environment free from contamination.

The RF Plasma Generator and Electrodes

This is the engine of the PECVD process. It consists of an RF power supply and a matching network that delivers energy into the chamber, typically through a set of electrodes. One electrode holds the substrate, while the other helps generate and shape the plasma. Control over RF power is a primary lever for influencing film properties.

The Gas Delivery System

This system delivers precise amounts of various precursor gases into the chamber. Modern systems use mass flow controllers (MFCs) to guarantee exact, repeatable gas ratios. The ability to mix multiple gases is essential for depositing complex materials like silicon nitride or silicon oxynitride.

The Substrate Stage and Heating

This is the platform where the object being coated (the substrate) is placed. It is almost always heated to provide some thermal energy to the surface. Precise temperature control is critical for managing film stress, adhesion, and density.

The Control System and Software

Modern PECVD equipment is managed by integrated software, often through a touch screen interface. This "brains" of the operation allows operators to create and run complex recipes that automate changes in gas flow, pressure, temperature, and RF power over time.

Understanding the Trade-offs

While powerful, PECVD is not without its complexities. Objectively evaluating its trade-offs is crucial for making an informed decision.

Film Properties vs. Deposition Rate

There is often a trade-off between deposition speed and film quality. Increasing RF power and gas flow can deposit films faster, but it can also lead to higher internal stress or incorporate unwanted elements (like hydrogen), altering the film's optical or electrical properties.

Complexity and Cost

A PECVD system is inherently more complex than a simple thermal CVD furnace or some Physical Vapor Deposition (PVD) systems. The inclusion of an RF generator, matching network, and advanced vacuum controls adds to the initial cost and maintenance requirements.

Potential for Plasma-Induced Damage

The energetic ions within the plasma can bombard the substrate surface. While this can be beneficial for creating dense films, it can also cause damage to highly sensitive electronic device layers. Fine-tuning the plasma conditions is key to mitigating this risk.

Making the Right Choice for Your Goal

The most important features of a PECVD system depend entirely on your specific application and priorities.

- If your primary focus is coating temperature-sensitive substrates (like plastics or organics): The most critical feature is the system's ability to produce high-quality films at the lowest possible temperatures.

- If your primary focus is research and development: Prioritize a system with maximum flexibility, including multiple gas lines, wide-range MFCs, and advanced recipe software for precise parameter control.

- If your primary focus is high-volume manufacturing: Emphasize features like a fast deposition rate, high system uptime, automation capabilities, and ease of maintenance to maximize throughput and yield.

By understanding how these core features solve the fundamental challenge of low-temperature deposition, you can select and operate the right equipment for your specific technical needs.

Summary Table:

| Feature | Function | Benefit |

|---|---|---|

| RF Plasma Source | Generates reactive species | Enables low-temperature deposition (200-400°C) |

| Vacuum Process Chamber | Provides clean, controlled environment | Ensures high film purity and quality |

| Precise Gas Delivery System | Delivers exact gas ratios via MFCs | Allows for complex material deposition |

| Temperature-Controlled Substrate Stage | Heats substrate for adhesion | Manages film stress and improves performance |

| Control System and Software | Automates process parameters | Enhances repeatability and ease of use |

Ready to enhance your laboratory's capabilities with advanced PECVD solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnace solutions tailored for diverse labs. Our product line, including PECVD Systems, Muffle, Tube, Rotary Furnaces, and Vacuum & Atmosphere Furnaces, is complemented by strong deep customization to precisely meet your unique experimental needs. Contact us today to discuss how we can optimize your thin film deposition processes and drive your research or production forward!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures