In short, dental ceramics are processed in furnaces to transform them from a weak, chalk-like state into a hard, dense, and aesthetically pleasing final restoration. This heating process, known as sintering, is what gives crowns, veneers, and bridges the necessary strength to withstand the immense forces of chewing.

The furnace is not simply an oven for hardening; it is a controlled environment that fundamentally re-engineers the ceramic's internal structure. This process is essential for achieving the required clinical durability and natural appearance of the final restoration.

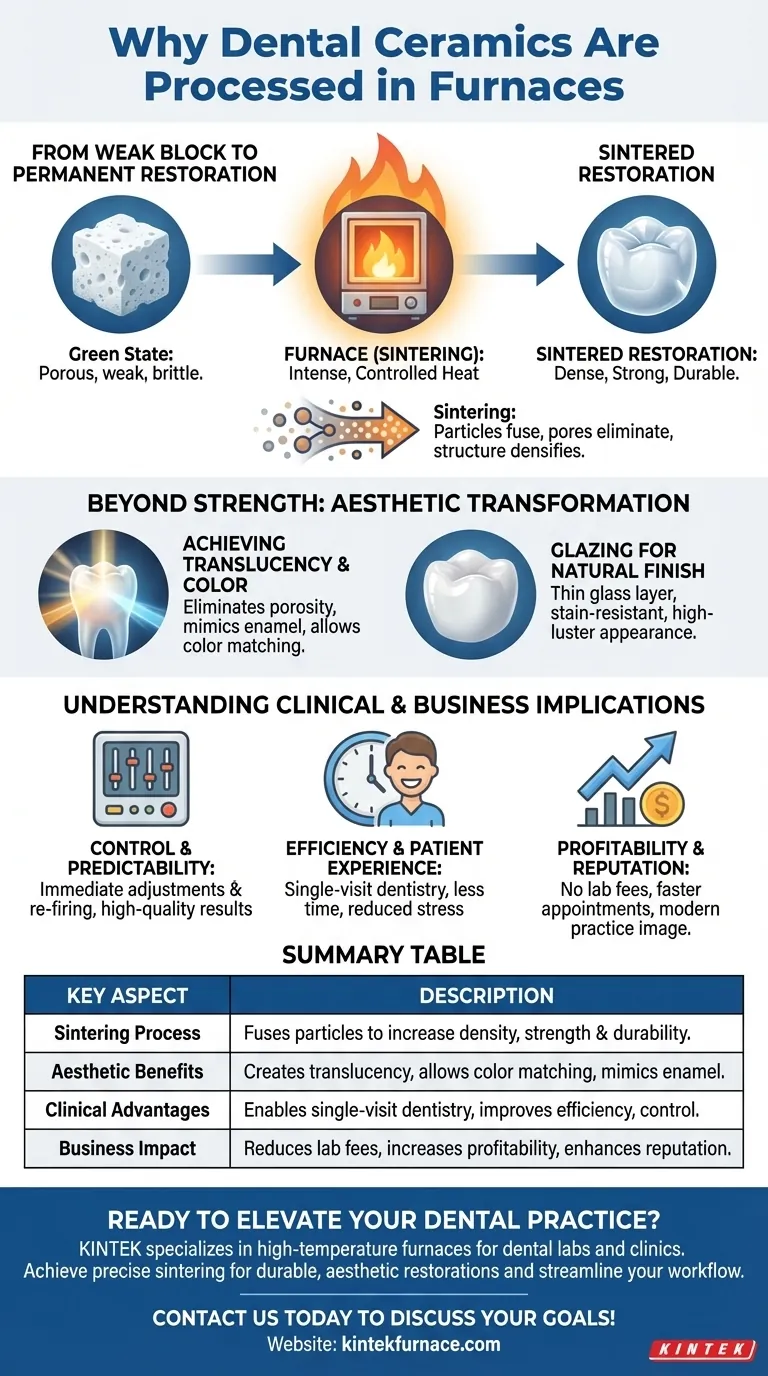

From Weak Block to Permanent Restoration

The journey of a dental ceramic from a pre-processed block to a final crown is a story of radical transformation. The furnace is the critical instrument that makes this transformation possible.

The "Green State"

Before firing, a ceramic restoration exists in a pre-sintered or "green state." It is a porous structure of compressed ceramic particles, often held together by a binder.

In this state, the material is soft enough to be easily milled by a machine or shaped by a technician. However, it is far too weak and brittle to function in the mouth.

The Role of Heat: Sintering

The furnace applies precise and controlled heat, initiating a process called sintering. During sintering, the furnace temperature is raised to just below the ceramic's melting point.

This intense heat causes the individual ceramic particles to fuse at their contact points. As they bond, the spaces and pores between them are eliminated, and the entire structure densifies and shrinks into a solid, monolithic mass.

The Result: Strength and Durability

The primary outcome of sintering is a dramatic increase in strength and fracture toughness. The unified, non-porous structure is capable of resisting the functional forces generated during chewing and grinding, ensuring the long-term survival of the restoration.

Beyond Strength: The Aesthetic Transformation

The furnace is equally critical for achieving the aesthetic qualities that make ceramics the material of choice for lifelike dental work.

Achieving Translucency and Color

The sintering process is what creates the ceramic’s translucency. By eliminating porosity, light can pass through the material in a way that mimics natural tooth enamel.

Furthermore, custom stains and shades can be applied and fired, allowing the final restoration to be perfectly matched to the patient’s surrounding teeth.

Glazing for a Natural Finish

In a final firing cycle, a thin layer of glass, or glaze, is fused to the restoration's surface. This creates a smooth, high-luster finish that is stain-resistant and kind to opposing teeth. The glaze seals any remaining microporosities and gives the crown its final, vital appearance.

Understanding the Clinical and Business Implications

For a dental practice, having an in-office furnace is about more than just material science; it’s about workflow and patient care.

Control and Predictability

An in-office furnace gives the clinician complete control over the final outcome. Adjustments to shade, contour, or fit can be made and re-fired immediately, ensuring a predictable and high-quality result without external lab delays.

Efficiency and Patient Experience

This control enables "single-visit dentistry." A patient can be prepared for a crown, have it digitally designed, milled, fired, and cemented in one appointment, drastically improving convenience and reducing patient stress.

Profitability and Reputation

By eliminating lab fees and reducing appointment times, an in-office furnace can significantly increase a practice's profitability. It also enhances its reputation as a modern, technologically advanced provider of care.

Making the Right Choice for Your Goal

Understanding the role of the furnace is key to optimizing your clinical workflow, whether you process ceramics in-office or work with a lab.

- If your primary focus is maximum control and single-visit convenience: An in-office furnace is the cornerstone of a complete chairside CAD/CAM system, giving you full command over the process.

- If your primary focus is minimizing initial investment: Partnering with a high-quality dental laboratory is an effective strategy, though it sacrifices the speed and on-the-spot control of an in-office workflow.

Ultimately, mastering the principles of ceramic processing empowers you to deliver stronger, more beautiful, and longer-lasting restorations for your patients.

Summary Table:

| Key Aspect | Description |

|---|---|

| Sintering Process | Fuses ceramic particles at high heat to eliminate pores and increase density, resulting in enhanced strength and durability. |

| Aesthetic Benefits | Creates translucency and allows for color matching, providing a natural appearance that mimics tooth enamel. |

| Clinical Advantages | Enables single-visit dentistry, improves workflow efficiency, and offers control over restoration quality. |

| Business Impact | Reduces lab fees, increases profitability, and enhances practice reputation through advanced technology. |

Ready to elevate your dental practice with advanced furnace solutions? KINTEK specializes in high-temperature furnaces tailored for dental laboratories and clinics. Leveraging our exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, and Vacuum Furnaces, with strong deep customization to meet your unique needs. Achieve precise sintering for durable, aesthetic restorations and streamline your workflow—contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations